A kind of nitric acid decolorization method and device

A decolorization and nitric acid technology, which is applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems that cannot meet the requirements and standards of downstream products, and achieve the effect of small investment and simple production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

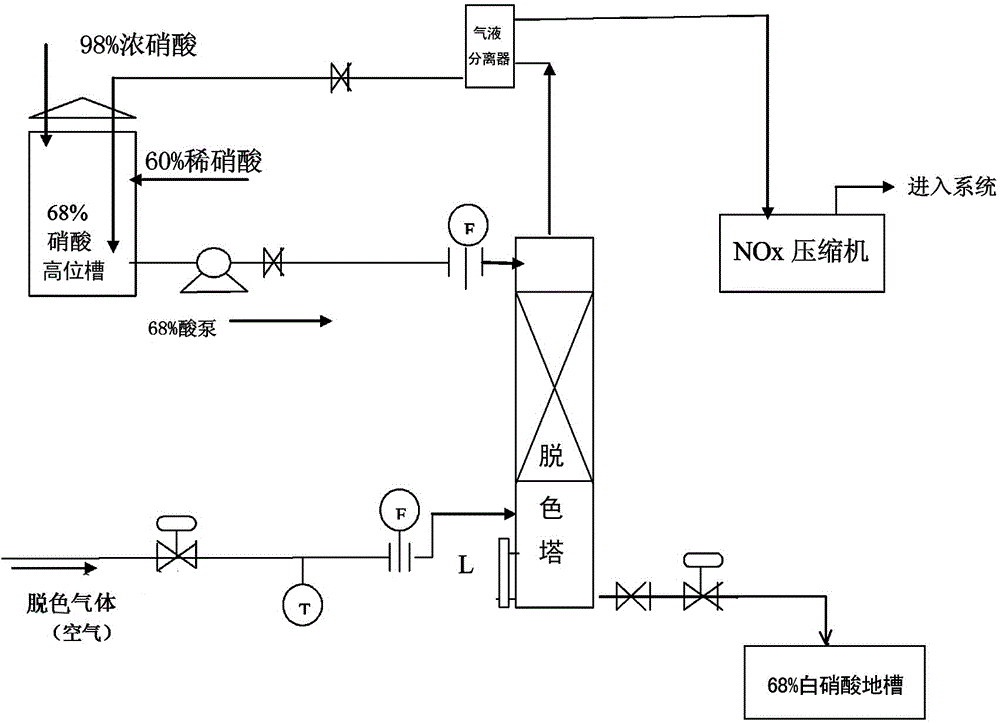

[0019] Such as figure 1 As shown, a kind of nitric acid stripping decolorization device provided by the present invention comprises a decolorization tower, the inlet pipe of the decolorization gas and the 68% white nitric acid storage tank (ground tank) are respectively connected to the bottom of the decolorization tower, and the high-level acid is respectively connected to the top of the decolorization tower through pipelines. The tank and the gas-liquid separator, an acid pump is also connected between the top of the decolorization tower and the high-level acid tank, the outlet pipe of the gas-liquid separator is connected to the NOx compressor, and the liquid outlet pipe of the gas-liquid separator is connected to the high-level acid tank.

[0020] Process flow of the present invention is:

[0021] In the elevated acid tank, add 0.75T of 60% dilute nitric acid and 0.25T of 98% concentrated nitric acid to prepare 68.% yellow nitric acid.

[0022] The outlet air of the air c...

Embodiment 2

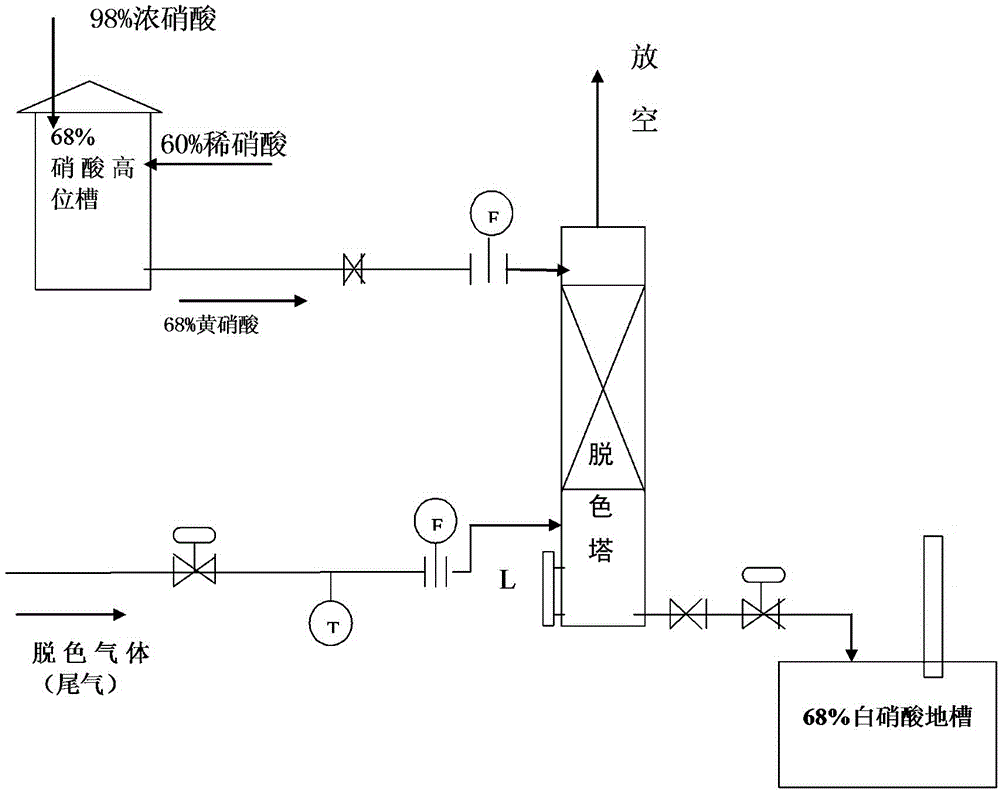

[0024] Embodiment two utilizes tail gas decolorization, can realize unpowered production:

[0025] Such as figure 2 As shown, in the high-level acid tank, mix 60% acid and 98% concentrated nitric acid in a certain proportion to prepare 68.% yellow nitric acid, which enters the upper part of the decolorization tower under the action of potential difference, and controls the flow rate of 8-10m 3 / h.

[0026] The exhaust gas from the outlet of the exhaust gas turbine (or expander) controls the flow (about 2000NM 3 / H), enter the decolorization tower and contact with the 68% acid from the upper part in countercurrent, the bleached 68% white nitric acid enters the 68% white nitric acid tank, and the decolorized tail gas is merged into the system tail gas and emptied together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com