Automatic curling machine

A crimping machine and automatic technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of low degree of automation, unsatisfactory, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

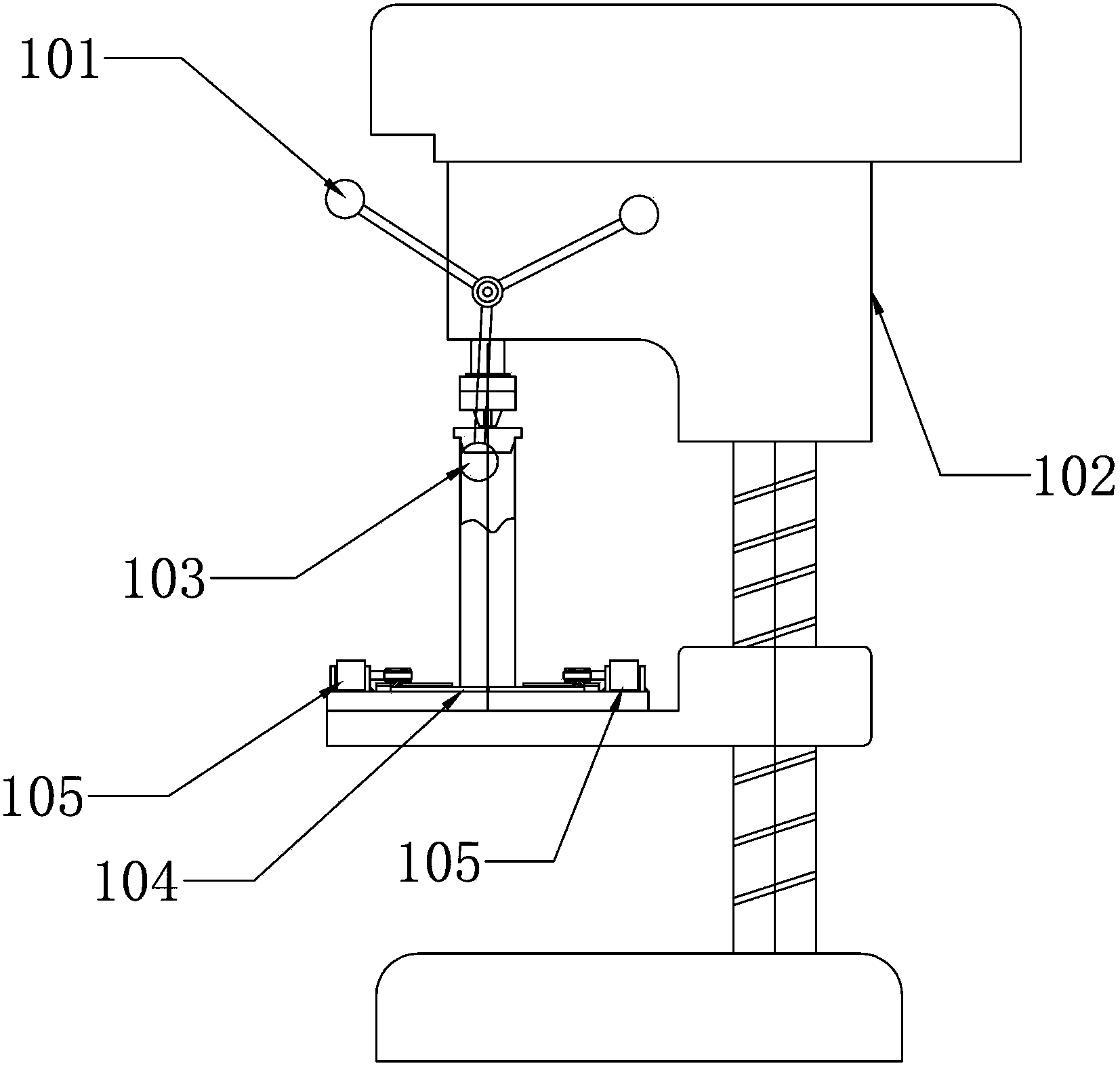

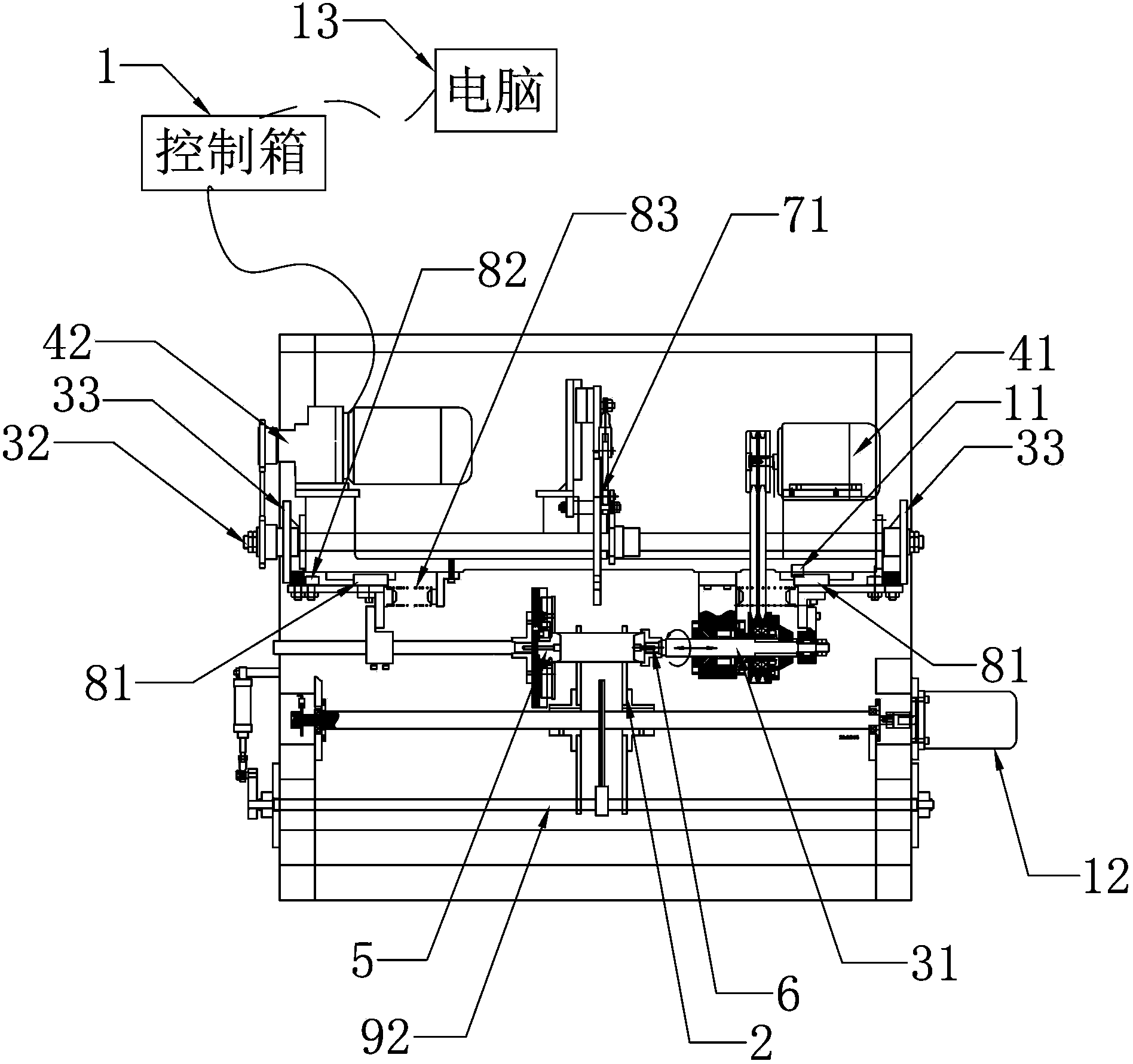

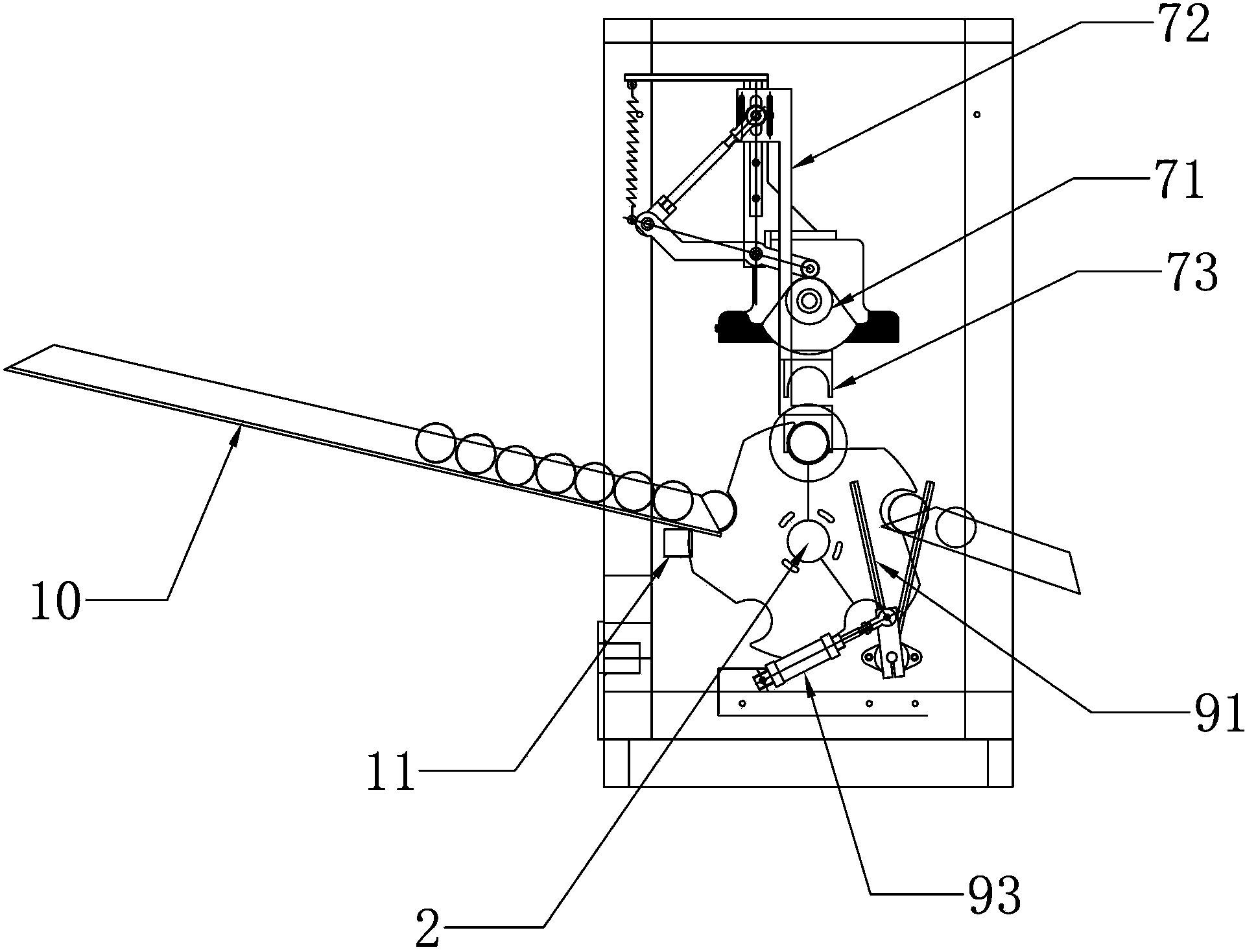

[0021] like figure 2 and image 3 As shown, the automatic crimping machine of the present invention includes a driving device, a feeding device, a crimping mold 5, a stretching mold 6, a tube holding device, a pulling device, a dial 2 and an electric control box 1; The electric control box 1 is used as the control center of the whole automatic crimping machine to control the orderly work of the automatic crimping machine; Feed shaft 31, feed camshaft 32, feed cam 33 and sliding mechanism are formed; The power source of described automatic crimping machine is provided by described driving device, comprises motor 41 and speed reducer 42; Described motor 41 is connected with the The feed shaft 31 is linked, and the reducer 42 is linked with the feed camshaft 32 through a chain; The cam 33 is interlocked, and the feed cam 33 is fixed on the feed cam shaft 32, and the sliding mechanism is connected with the feed cam shaft 32; Cooperate to complete the curling operation of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com