Flaring machine of plastic-steel-plastic composite pressure pipe

A technology of steel-plastic composite and pressure pipes, which is applied in the field of auxiliary installation equipment for steel-plastic composite pressure pipes, can solve the problems of high labor intensity for operators, small diameter of applicable pipes, and low degree of automation, so as to improve the degree of installation automation and reduce work Strength, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

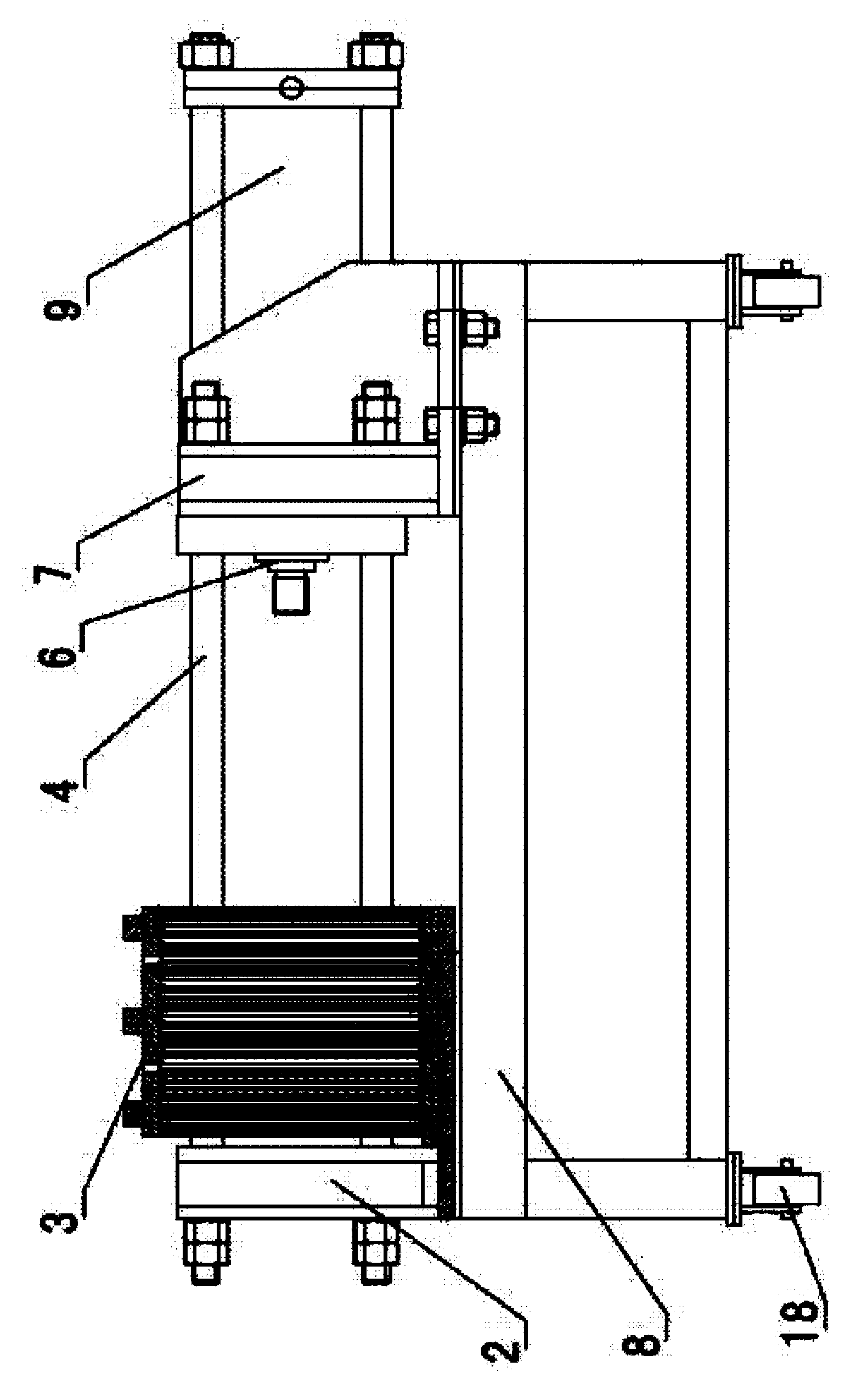

[0023] As shown in Figure l to image 3 A steel-plastic composite pressure pipe flaring machine shown is characterized in that it includes a frame 8, a flaring mechanism horizontally arranged above the end of the frame 8, and a clamping mechanism vertically arranged at the other end of the frame 8 and a control system; the flaring mechanism includes a flaring drive device horizontally fixed on the top of the frame 8 and a profiling indenter 5 located at the output end of the flaring drive device; The clamping drive device at the end of the frame 8 and the split ring clamp fixedly arranged above the frame 8; the axis of the ring clamp coincides with the axis of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com