Mixing station host system, mixing station comprising host system, and mixing equipment comprising host system

A main engine system and mixing main engine technology, which is applied in the field of mixing plants and mixing equipment, can solve the problems of unbalanced air pressure, high work intensity, easy to produce dragging scales, pulling scales, etc., to reduce dust pressure, prevent weighing, and suppress dust the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

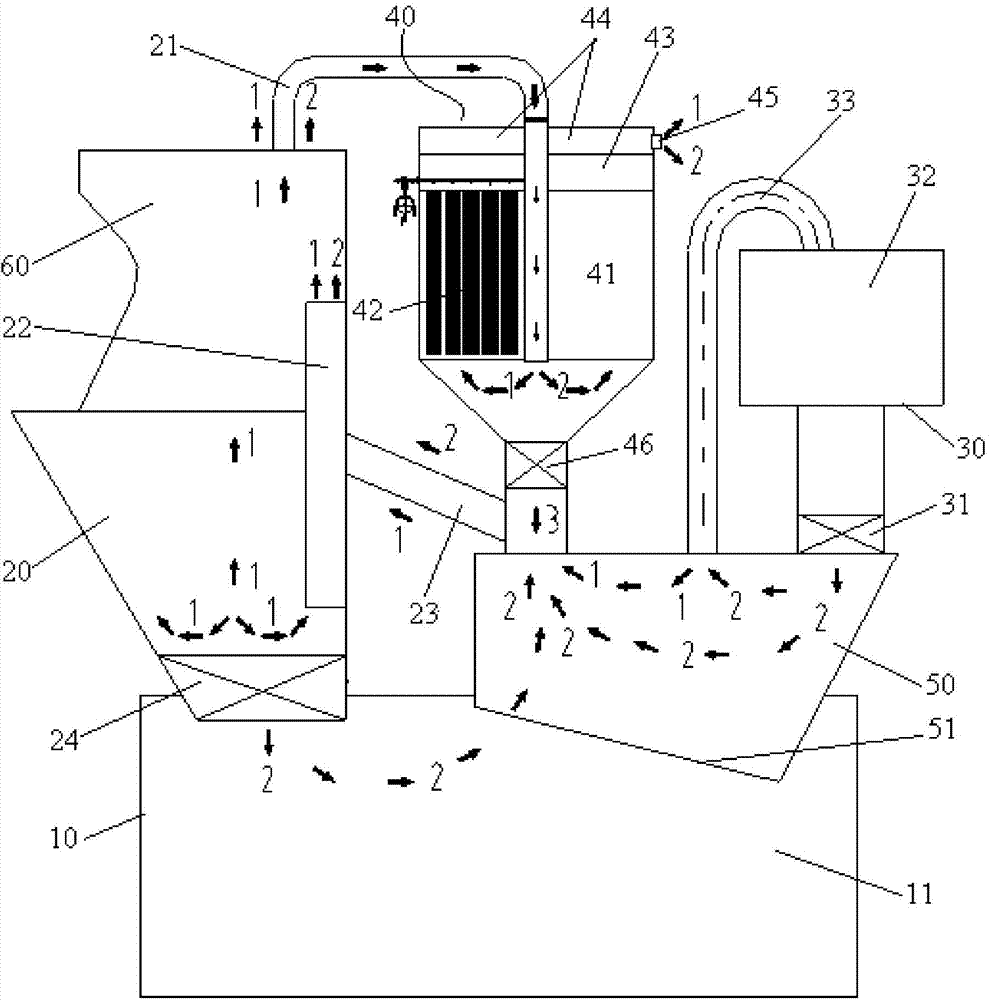

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

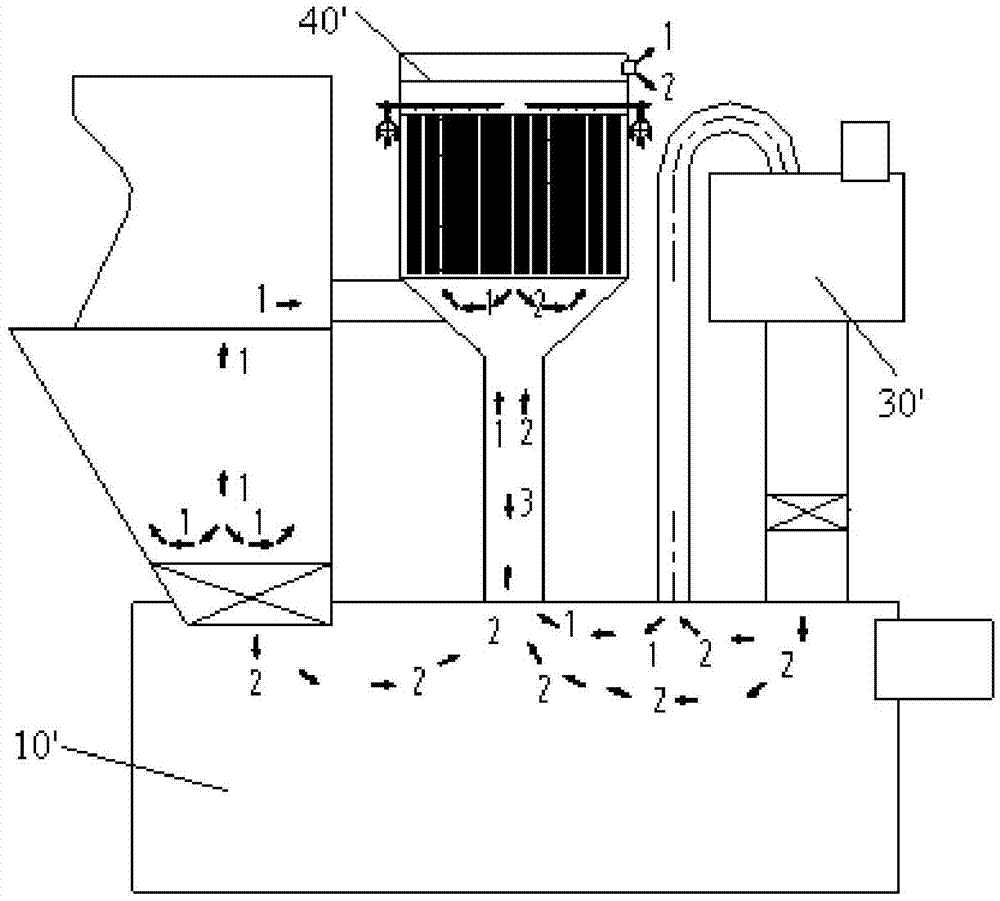

[0025] figure 2 The direction of the middle arrow indicates the flow direction of dust.

[0026] Such as figure 2 As shown, according to the embodiment of the present invention, the host system of the mixing station includes a mixing host 10 , an aggregate intermediate bin 20 , a powder scale 30 , a dust collector 40 and a transition hopper 50 . The aggregate intermediate bin is respectively connected to the main mixer 10 and the dust collector 40 , the powder scale 30 is connected to the transition hopper 50 , and feeds into the main mixer 10 through the transition hopper 50 . The transition hopper 50 includes a transition feed port, a transition discharge port 51 , a first dust removal communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com