Tool holder and tool holder attachment structure

一种工具保持、安装结构的技术,应用在制造工具、金属加工机械零件、定位装置等方向,能够解决无法主轴安装工具保持件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention is particularly applicable to tool holder mounting structures of the BT type in which the tapered shank of the tool holder is positioned within the tapered bore of the spindle.

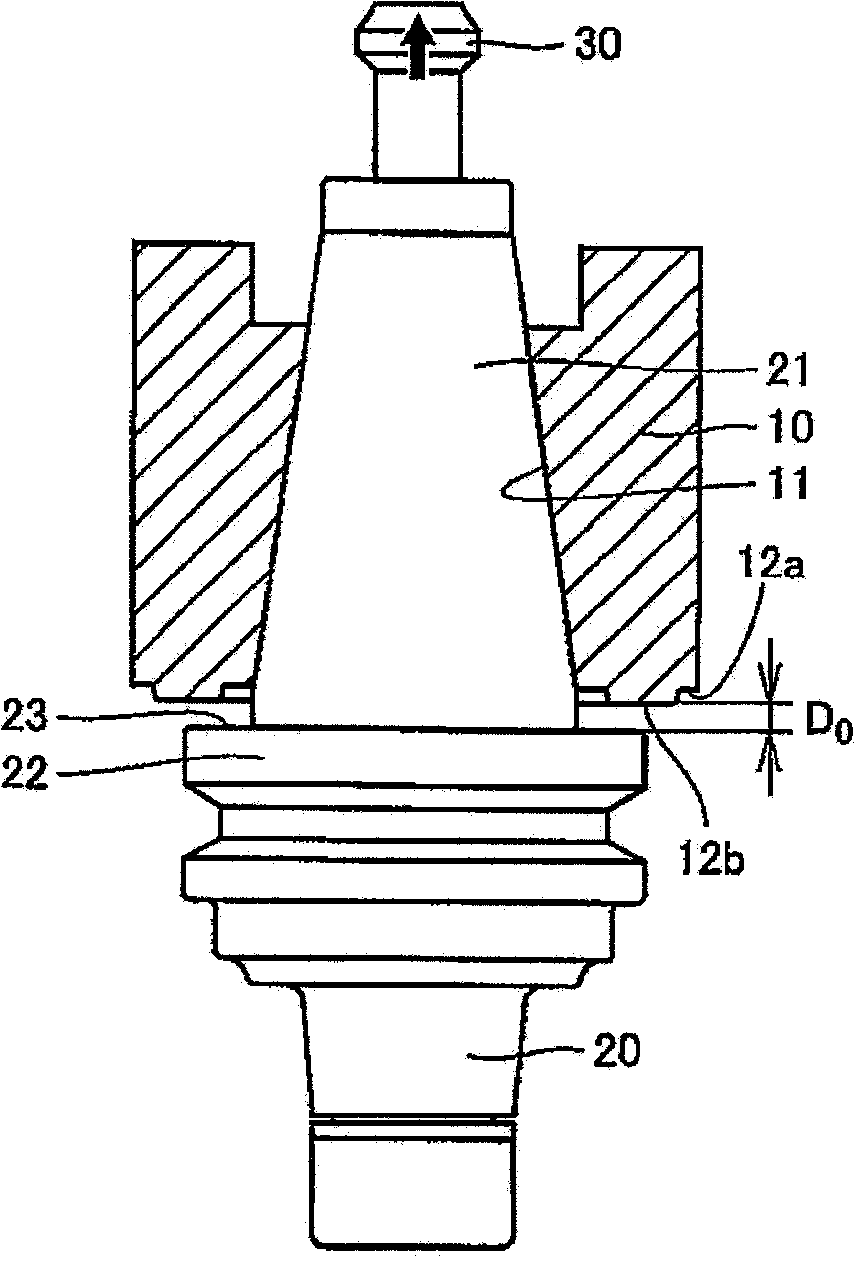

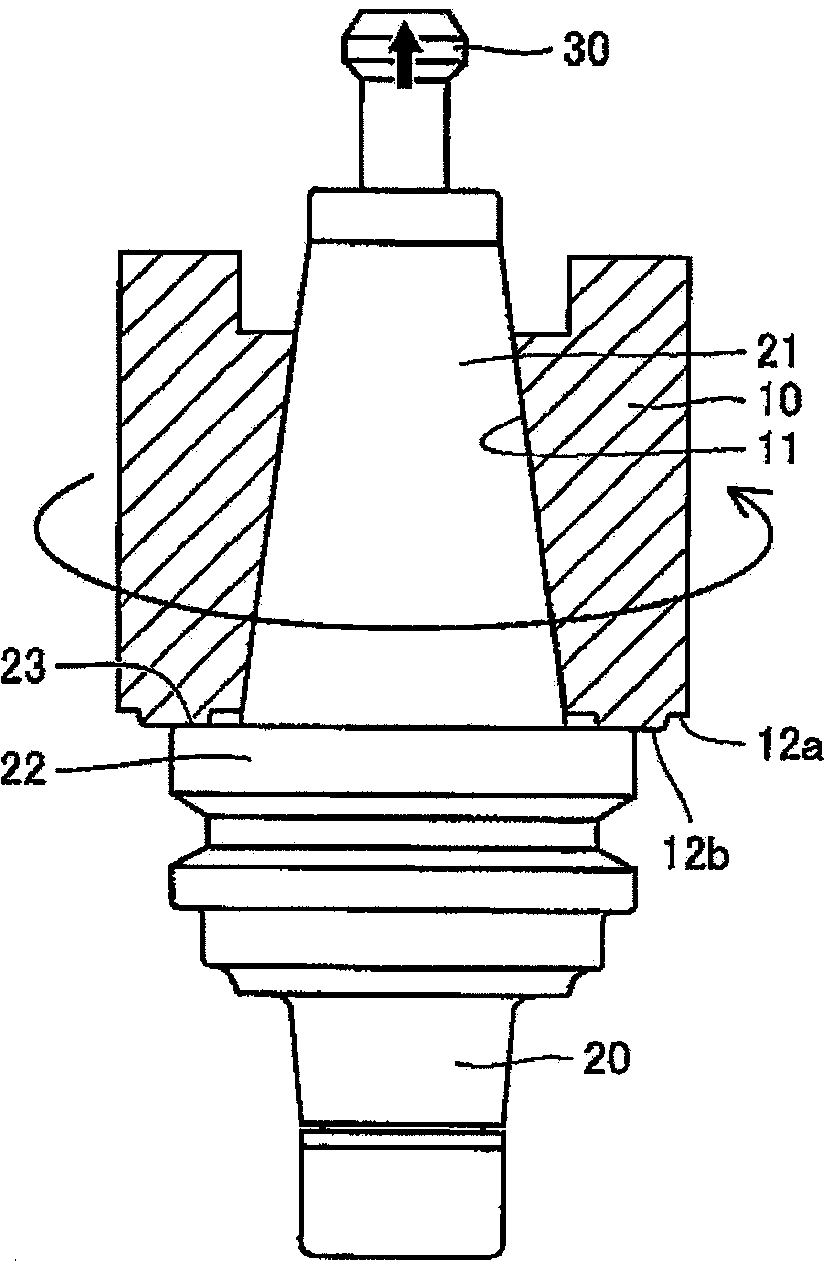

[0035] figure 1 It is a cross-sectional view showing a state where the tool holder is attached to the tapered hole of the main shaft of the machine tool. The main shaft 10 has a tip surface 12 a serving as a reference end surface and a tapered hole 11 extending axially inward from the tip surface 12 a.

[0036] The tool holder 20 includes a tapered shank portion 21 and a collar portion 22 , wherein the tapered shank portion 21 fits into the tapered hole 11 of the spindle 10 , and the collar portion 22 is held by a manipulator during automatic tool exchange. The flange portion 22 has a flange portion end surface 23 facing the distal end surface 12 a of the main shaft 10 .

[0037] figure 1 It shows a state where the tapered shank portion 21 of the mounting tool holder 20 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com