Positioning fixture for assembling flexible printing circuit (FPC)

A flexible circuit board and positioning fixture technology, which is applied in the directions of printed circuits, printed circuit manufacturing, and assembling printed circuits with electrical components, can solve the problems of difficulty in ensuring the consistency of positioning pins and countersunk holes, affecting the positioning accuracy of positioning pins, etc. Accurate verticality, improved assembly accuracy, and easy installation of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

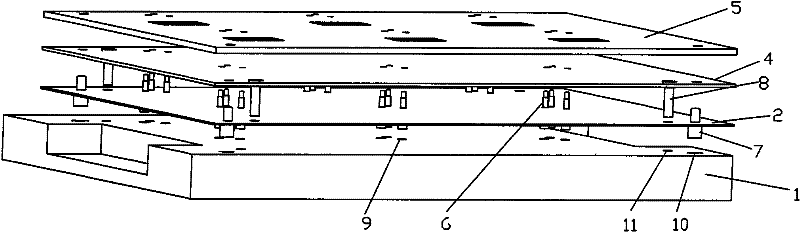

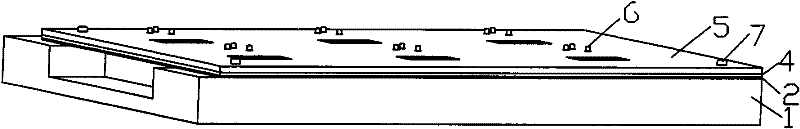

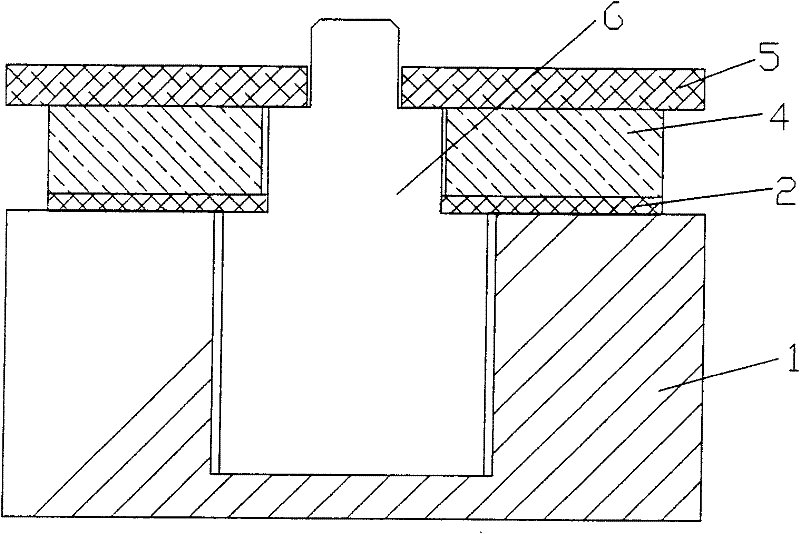

[0027] Such as figure 1 As shown, a positioning fixture for flexible circuit board assembly is composed of a layer of bottom plate 1, a layer of thin steel sheet 2 on the bottom plate 1, a layer of lock pressing plate 4 on the thin steel sheet 2, and a layer of lock pressing plate 4. One layer of FPC carrier board 5, vertically penetrates the thin steel sheet 2, the product positioning pin 6 of the lock pressing plate 4 and the FPC carrier board 5 and the carrier board positioning pin 7, vertically penetrates the locking pressing plate 4 and the thin steel sheet 2 downwards and The above-mentioned two-layer board and two kinds of positioning pins are fastened to the screws 8 on the bottom plate 1.

[0028] The processing requirements of each component are as follows:

[0029] The upper surface of the bottom plate 1 is processed with the counterbore 9 for the product positioning pin, the counterbore 10 for the positioning pin of the carrier plate, and the assembly screw hole 1...

Embodiment 2

[0049] Such as Figure 5 As shown, a positioning fixture for assembly of a flexible circuit board (FPC) according to the present invention consists of a base plate 1, a lower thin steel sheet 2 (1), a middle transition plate 3, and an upper thin steel sheet 2 ( 2), one layer of locking plate 4, one layer of FPC carrier board 5, vertically penetrate the five-layer board except the bottom plate 1 and insert the product positioning pin 6 of the bottom plate 1 and the carrier plate positioning pin 7, vertically penetrate two layers of thin steel sheets , the intermediate transition plate 3 and the lock pressing plate 4 and the screws 8 fastening the above-mentioned four-layer plate and two kinds of positioning pins on the bottom plate 1.

[0050] The processing requirements of each component are as follows:

[0051] The lower thin steel sheet 2 (1), the upper thin steel sheet 2 (2), the intermediate transition plate 3, the lock plate 4, and the FPC carrier plate 5 process holes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com