Process method of electromagnetic riveting composite material

A composite material and electromagnetic riveting technology, which is applied in the field of electromagnetic riveting composite materials and composite material structure riveting, to achieve the effect of ensuring riveting quality and improving riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

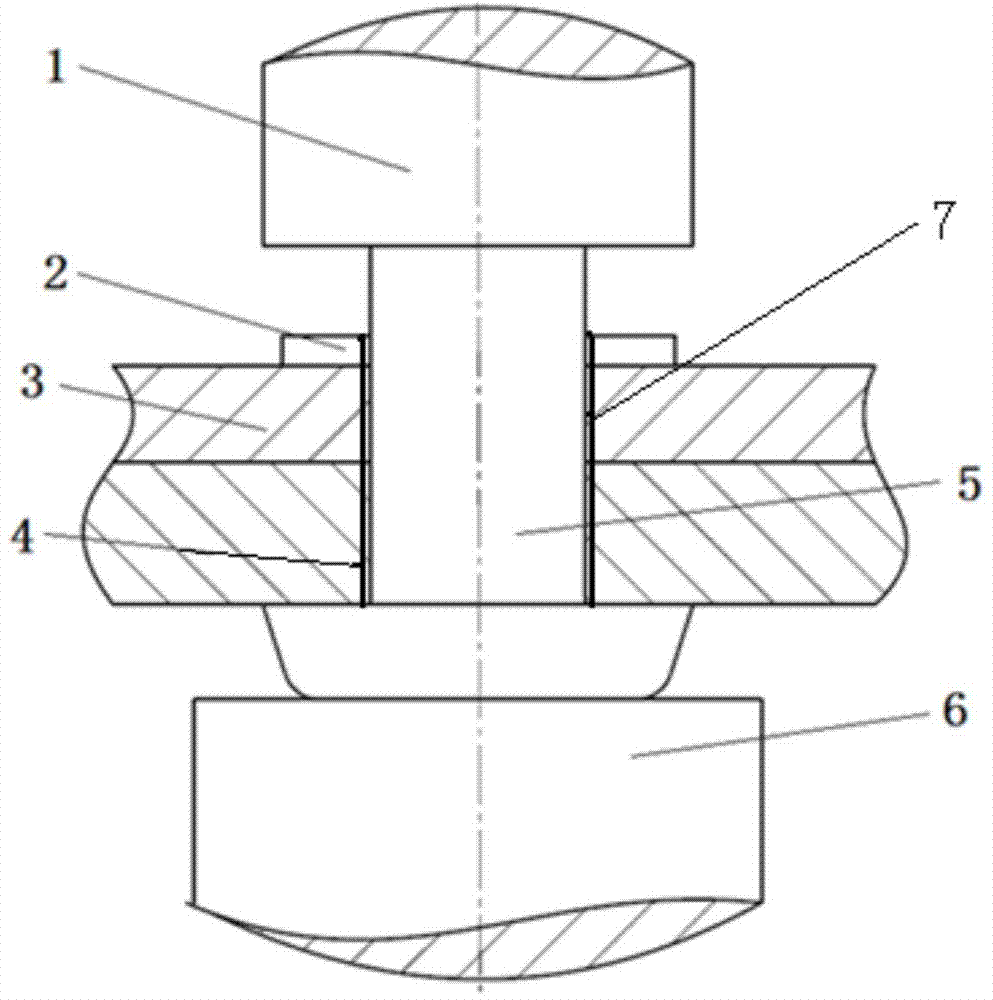

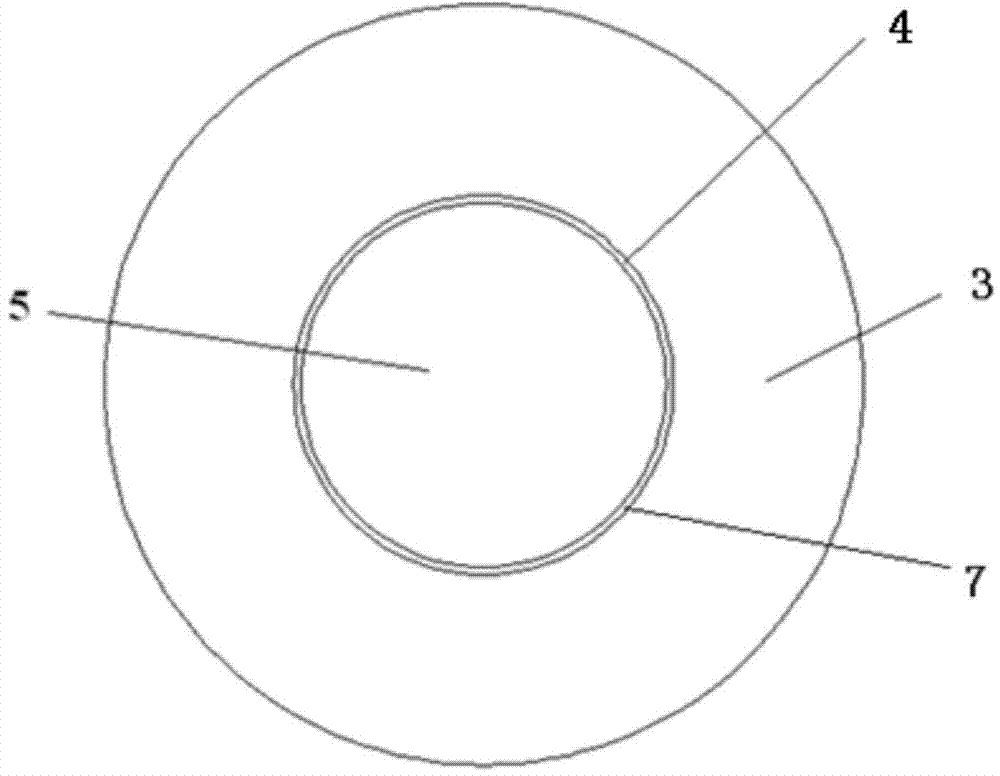

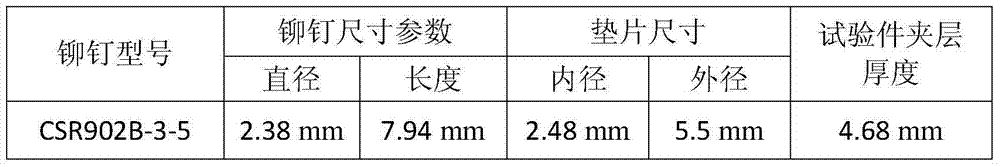

[0011] The riveting equipment 1 used in this embodiment is the electromagnetic riveting equipment currently used in production, and the top iron 6 is also a conventional tool used in production. First make rivet holes 4 on the composite material plate 3 according to the diameter of the rivets, and the hole making tools and hole making requirements are in accordance with HB / Z223.21‐2003 Aircraft Assembly Process Part 21 Riveting of composite materials; select titanium niobium rivets and titanium alloy pads Electromagnetic riveting equipment is used to select the appropriate riveting voltage for riveting. The aperture size of the rivet hole is the diameter of the rivet plus 0.1mm, not exceeding the diameter of the rivet plus 0.2mm; the inner diameter of the gasket is the diameter of the rivet plus 0.1mm, not exceeding Add 0.2mm to the diameter of the rivet; the thickness of the gasket is 0.8mm to 1.0mm. The aperture size is generally the diameter of the rivet plus 0.1mm to 0.2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com