Matching device and matching method for ultrasonic power supply

A technology of matching device and matching method, which is applied in the direction of fluid using vibration, etc., can solve problems such as complex circuit structure, unfixed output frequency, reliability and safety impact, and achieve wide application prospects, low cost and real-time response fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

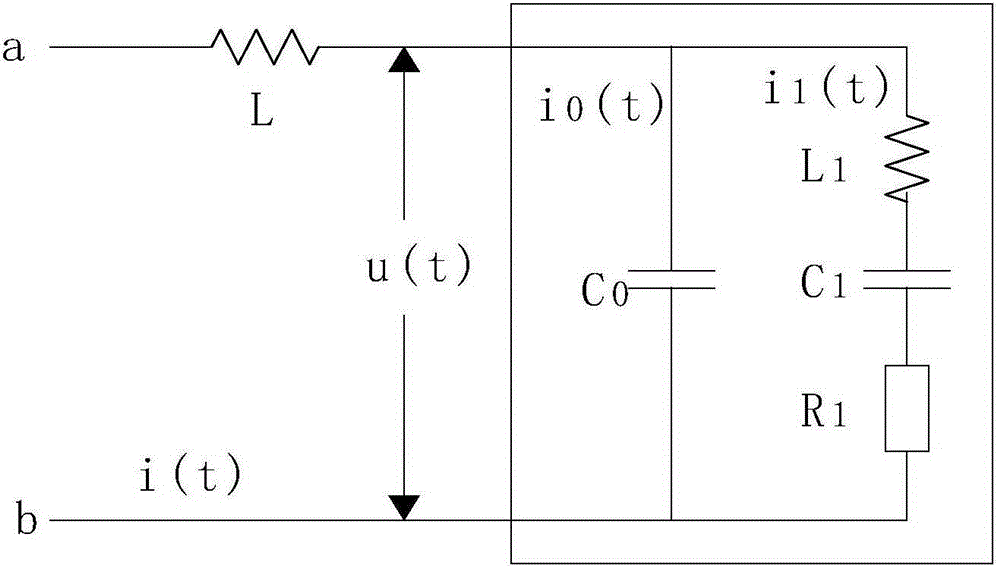

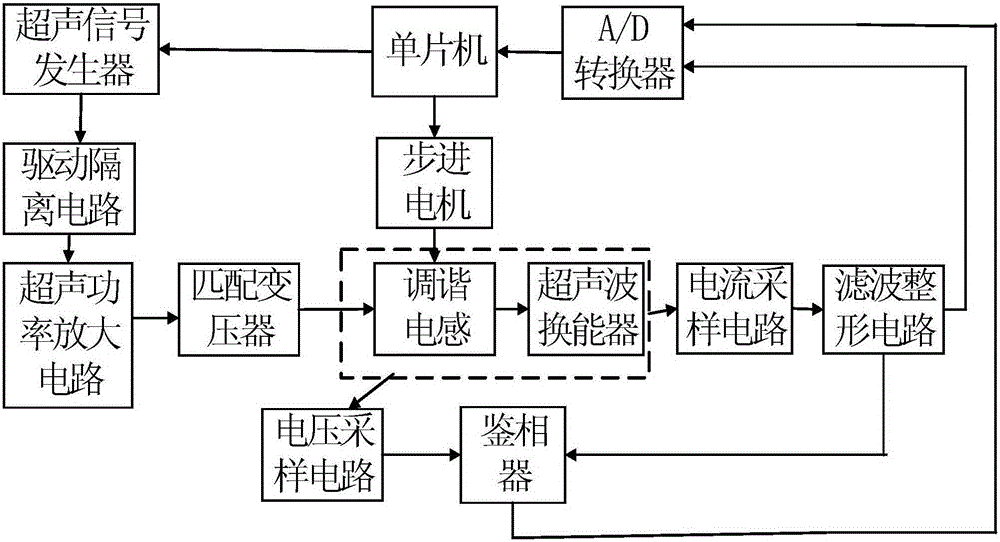

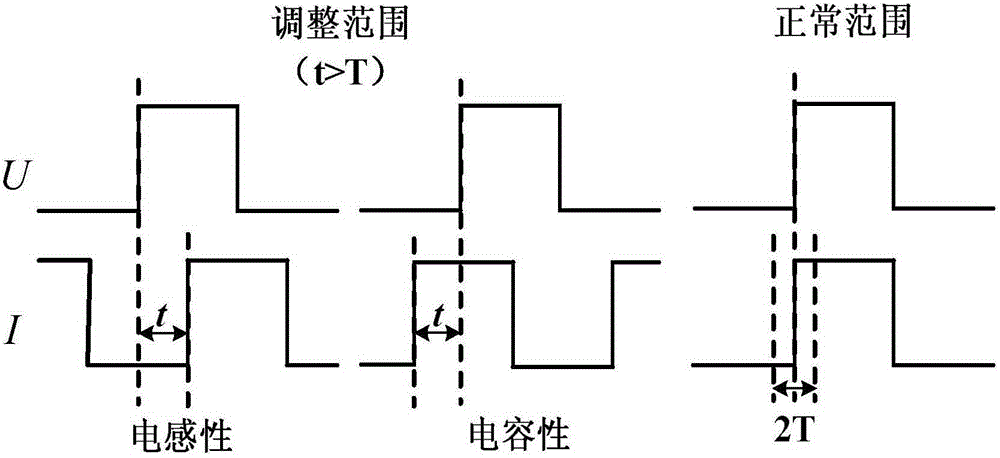

[0035] Such as Figure 2~4 As shown, a matching device for an ultrasonic power supply, which includes an ultrasonic signal generator, a drive isolation circuit, an ultrasonic power amplifier circuit, a matching transformer, a tuning inductor, an ultrasonic transducer, a voltage sampling circuit, a current sampling circuit, a filter shaping circuit, Phase detector, A / D converter, microcontroller and stepping motor; among them,

[0036] An ultrasonic signal generator, the output end of which is connected to the driving isolation circuit for generating ultrasonic driving signals;

[0037] A drive isolation circuit, the output end of which is connected to the ultrasonic power amplifier circuit for receiving the ultrasonic drive signal and driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com