Method for making soft and hard double-sided circuit board

A technology of double-sided circuit board and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of substrate quality, uneven surface of FPC substrate, product scrapping, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] Such as figure 1 Shown, a kind of hard and soft double-sided circuit board manufacturing method comprises the following steps:

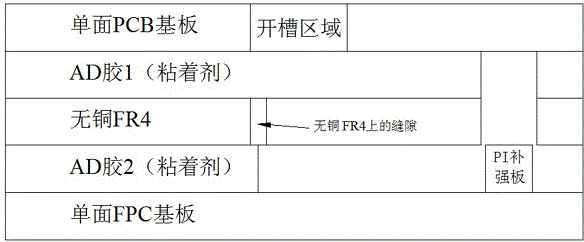

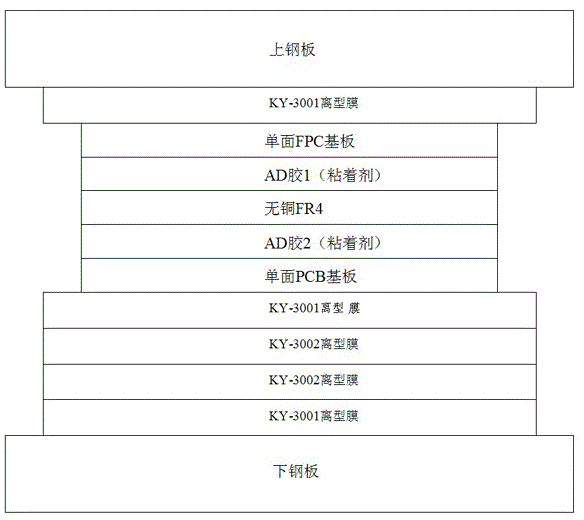

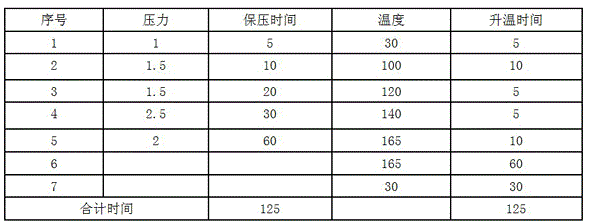

[0021] a) According to the thickness of the product, choose a PCB single-sided substrate plus a copper-free FR4 to replace the original single-sided substrate, for example: the thickness of the original single-sided substrate is 1.0MM, now use a 0.8MM single-sided substrate plus A piece of 0.2MM copper-free FR4 is synthesized and replaced, and the specific material selection can be freely matched according to the thickness of the product; the thickness of the copper-free FR4 material needs to be matched according to the thickness of the PI reinforcing plate, and the thickness of the FR4 material is the same as that of the PI The thickness difference of the reinforcing plate is controlled within ±0.05MM, otherwise the raised phenomenon on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com