Device for online monitoring temperature of contact of substation equipment

A contact temperature and monitoring device technology, which is applied to measuring devices, thermometers, thermometers with physical/chemical changes, etc., can solve problems such as damage, equipment monitoring failure, and small space, so as to achieve convenient installation and use, ensure safe operation, The effect of simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

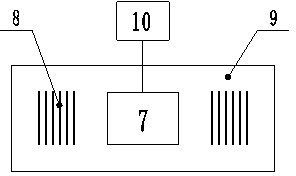

[0029] Such as figure 1 As shown, the online monitoring device for substation equipment contact temperature of the present invention includes a cross-region monitoring master station computer 1 installed in a cross-region monitoring master station, a monitoring center computer 2 installed in a substation monitoring center, and a bus gateway installed in a power distribution room 3. A temperature collector 4 installed on the switch cabinet and a passive wireless temperature sensor 5 installed on the surface of the tested element.

[0030] The cross-area monitoring master station computer 1 is connected with a plurality of monitoring center computers 2, and the monitoring center computer 2 is connected with a plurality of bus gateways 3, and the bus gateway 3 is connected with a plurality of temperature collectors 4 through a communication bus, so that Described temperature collector 4 links to each other with a plurality of passive wireless temperature sensors 5 through radio f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com