Wallpaper with perspective effect and fabrication process thereof

A technology of perspective effect and production process, applied in household appliances, printing, printing machines, etc., can solve the problems of high ink viscosity, poor fluidity, slow printing speed, etc., to achieve thickness and smoothness, enhanced controllability, and production. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

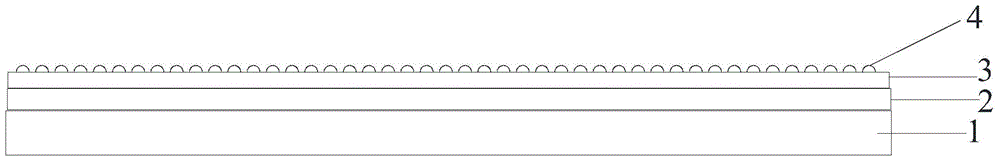

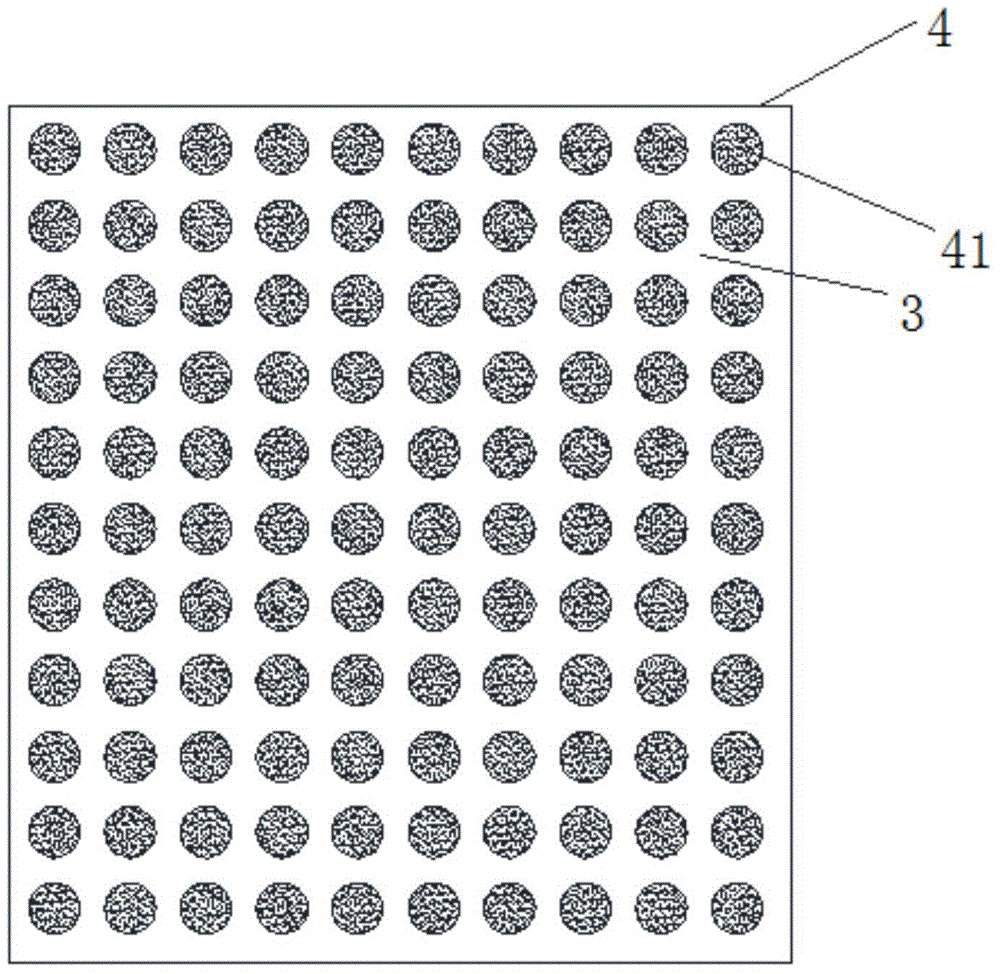

[0048] The wallpaper with perspective effect in this embodiment has the structure as mentioned above, and its manufacturing process is as follows:

[0049] Print the base color on the base layer to form the base color layer, and then use the water-based printing resin to print patterns on the base color layer by gravure printing process to form a pattern decoration layer, and form a coarse dot pattern see-through layer on the pattern decoration layer.

[0050] Wherein, the water-based printing resin is made of the following parts by weight:

[0051] Acrylic resin 100 parts;

[0052] Filling 80 parts;

[0053] Thickener 5 parts.

[0054] Wherein, the production process of the water-based printing resin is: adding the synthesized acrylic resin into the mixing tank, grinding the mixture of the acrylic resin and the filler in the mixing tank with grinding equipment; then adding the thickener into the mixing tank, Stir evenly, that is, the water-based printing resin for rough do...

Embodiment 2

[0059]The wallpaper with perspective effect in this embodiment has the structure as mentioned above, and its manufacturing process is as follows:

[0060] Print the base color on the base layer to form the base color layer, and then use the water-based printing resin to print patterns on the base color layer by gravure printing process to form a pattern decoration layer, and form a coarse dot pattern see-through layer on the pattern decoration layer.

[0061] Wherein, the water-based printing resin is made of the following parts by weight:

[0062] Acrylic resin 100 parts;

[0063] Filling 20 parts;

[0064] Thickener 10 parts.

[0065] Wherein, the production process of the water-based printing resin is: adding the synthesized acrylic resin into the mixing tank, grinding the mixture of the acrylic resin and the filler in the mixing tank with grinding equipment; then adding the thickener into the mixing tank, Stir evenly, that is, the water-based printing resin for rough do...

Embodiment 3

[0070] The wallpaper with perspective effect in this embodiment has the structure as mentioned above, and its manufacturing process is as follows:

[0071] Print the base color on the base layer to form the base color layer, and then use the water-based printing resin to print patterns on the base color layer by gravure printing process to form a pattern decoration layer, and form a coarse dot pattern see-through layer on the pattern decoration layer.

[0072] Wherein, the water-based printing resin is made of the following parts by weight:

[0073] Acrylic resin 100 parts;

[0074] Filling 60 parts;

[0075] Thickener 8 parts.

[0076] Wherein, the production process of the water-based printing resin is: adding the synthesized acrylic resin into the mixing tank, grinding the mixture of the acrylic resin and the filler in the mixing tank with grinding equipment; then adding the thickener into the mixing tank, Stir evenly, that is, the water-based printing resin for rough do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com