Pavement construction with hierarchically completely encapsulated roadbed and construction method thereof

A technology of subgrade and structure, which is applied in the direction of on-site paved condensate pavement, roads, roads, etc., can solve problems such as uneven settlement, large footprint, and deepening of surface water and groundwater. The effects of small subgrade disease and damage, avoiding mud pumping on the road surface, and preventing road surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

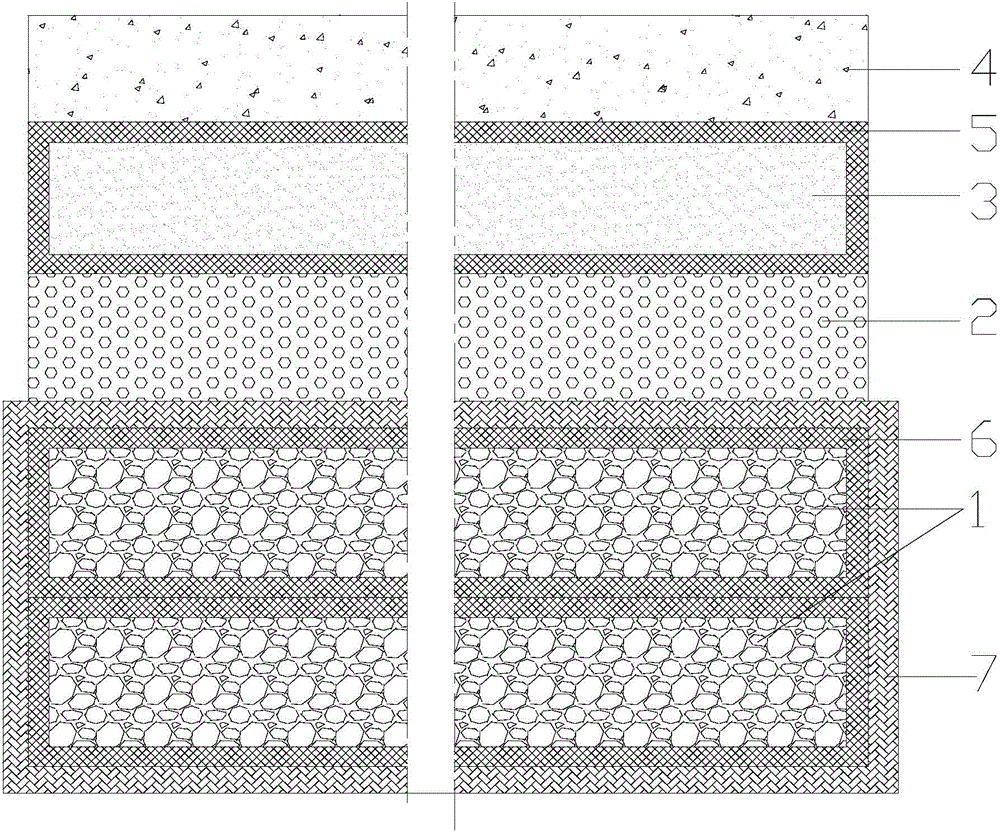

[0033] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the overlapping connection structure of the roadbed waterproof reinforcement layer and the waterproof vibration-damping functional layer of the present invention; Layer 2 and roadbed 1, the roadbed 1 is a multi-layer structure, each layer is fully covered with a roadbed waterproof reinforcement layer 6 in a sealed manner, and superimposed to form a whole roadbed 1; as shown in the figure, an independent multi-layer structure is formed Layer structure, relatively independent between layers, can be more coordinated for larger external forces to avoid uneven settlement; at the same time, the layers are fully covered with superimposed roadbeds formed by roadbed waterproof reinforcement layers, and the overall water content is better controlled , the reinforcement and hoop restraining capacity are more significant, and the bearing capacity and stability of the roadbed can be greatly impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com