Metalworking fluids filtration system

A metalworking fluid and filtration system technology, applied in the direction of lubricating compositions, etc., can solve the problems of high cost, reduced service life and work efficiency, and short service life of cutting fluid, so as to maintain performance, meet space requirements, and service life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

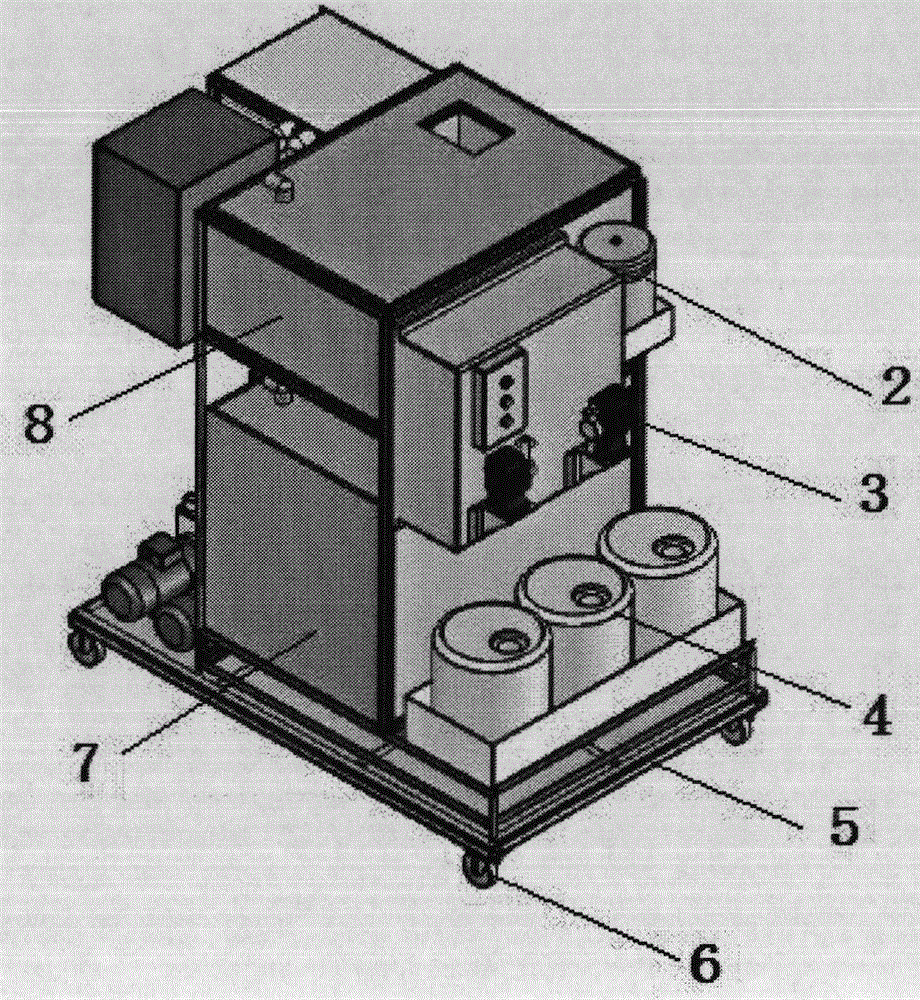

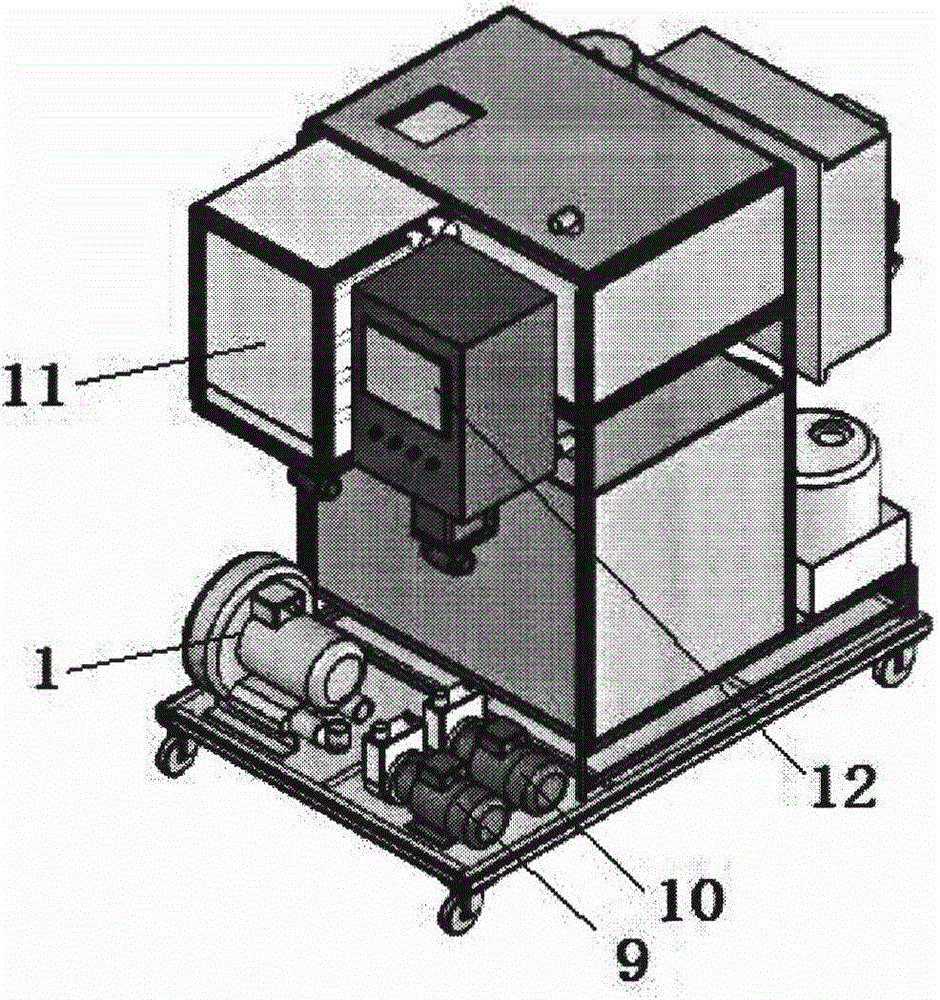

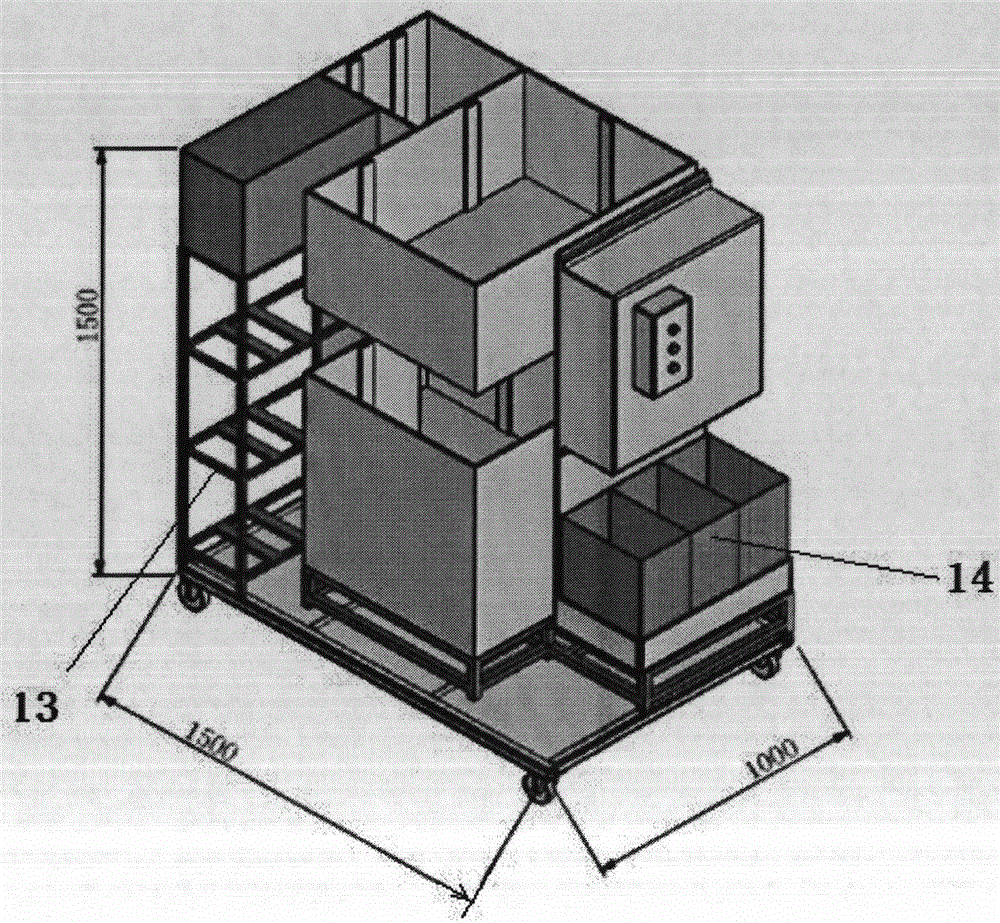

[0041] Such as Figure 1-2 As shown, a metalworking fluid filtration system according to an embodiment of the present invention includes a box body, equipment disposed in the box body, and a bottom bracket 5, and the equipment in the box body includes a vacuum filtration system and a precision filtration system 11 , a liquid storage system, a pumping system and an intelligent control system 12, the liquid storage system includes a first liquid storage tank 7 and a second liquid storage tank 8, and the pumping system includes a first pumping system 9 and a second pump send system 10;

[0042] There is a vacuum pump 1 in the vacuum filtration system, which removes debris and oil stains by vacuuming, and filters out fine solid particles and slick oil. The vacuum filtration system can filter out tiny solid particles of 5 microns; The liquid is sent to the precision filtration system 11.

[0043] The precision filtration system 11 is equipped with multi-layer filter paper, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com