Biomass dry-distillation, pyrolysis and gasification device

A technology of pyrolysis gasification and biomass, which is applied in the fields of biofuels, special forms of dry distillation, chemical industry, etc., can solve the problems of low waste utilization rate, waste of resources, easy slagging, etc., and achieve thorough biomass dry distillation and reduce The effect of high production cost and gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

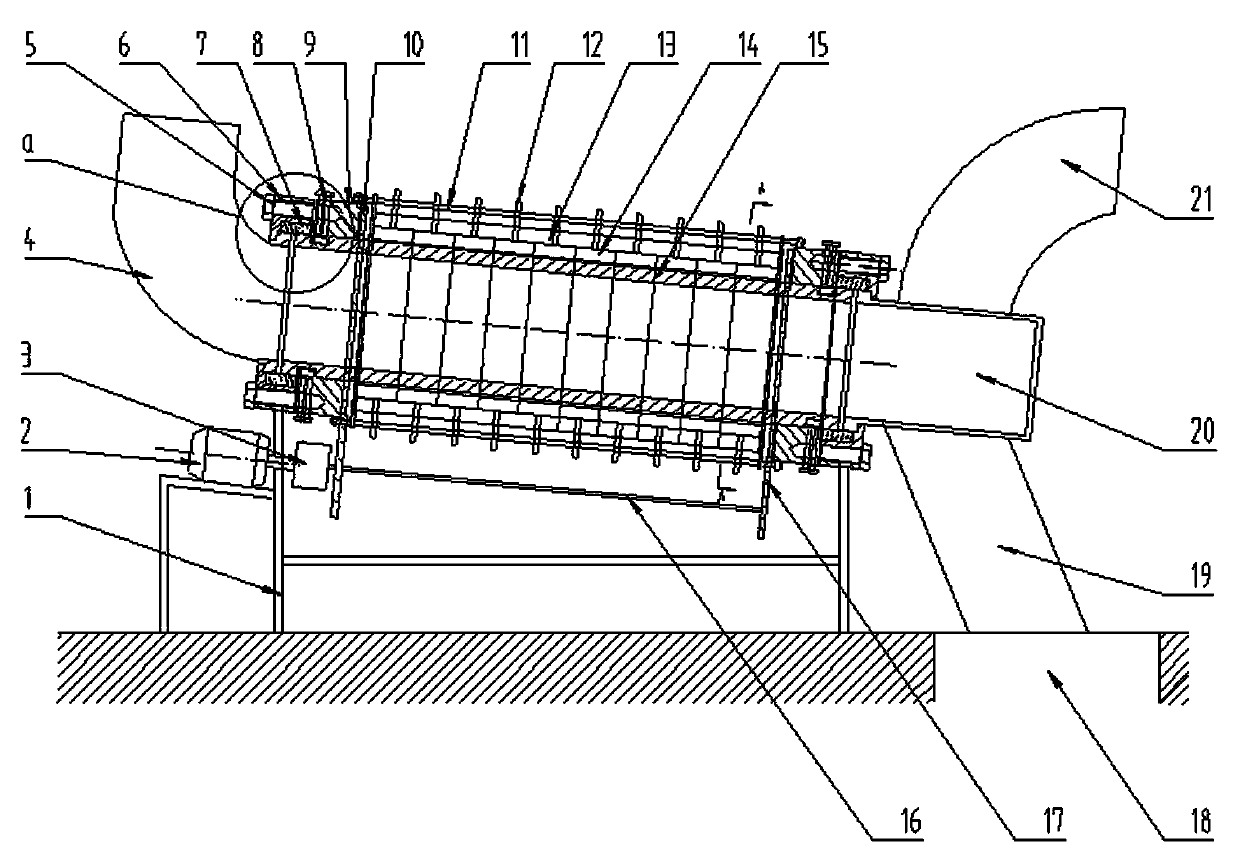

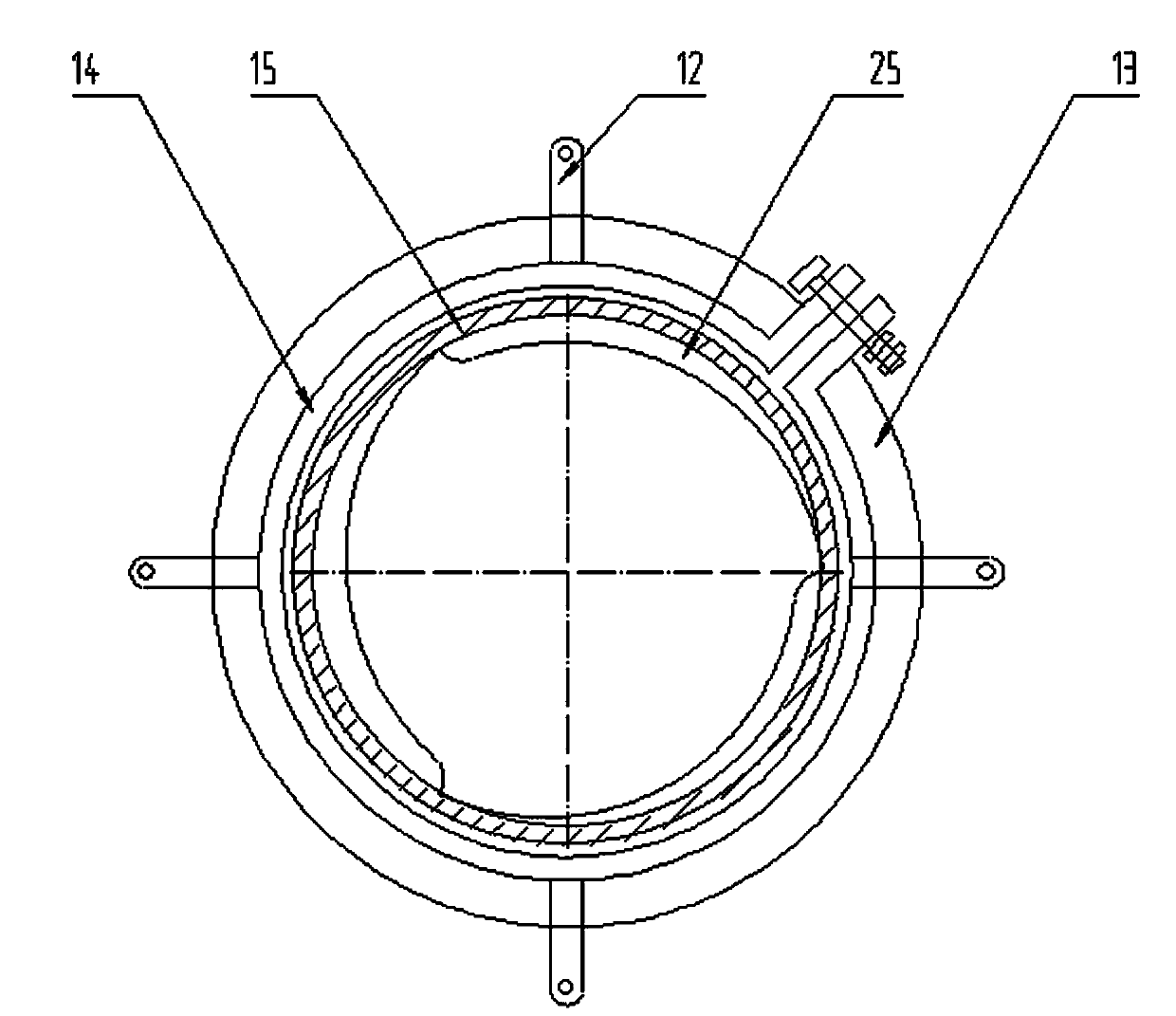

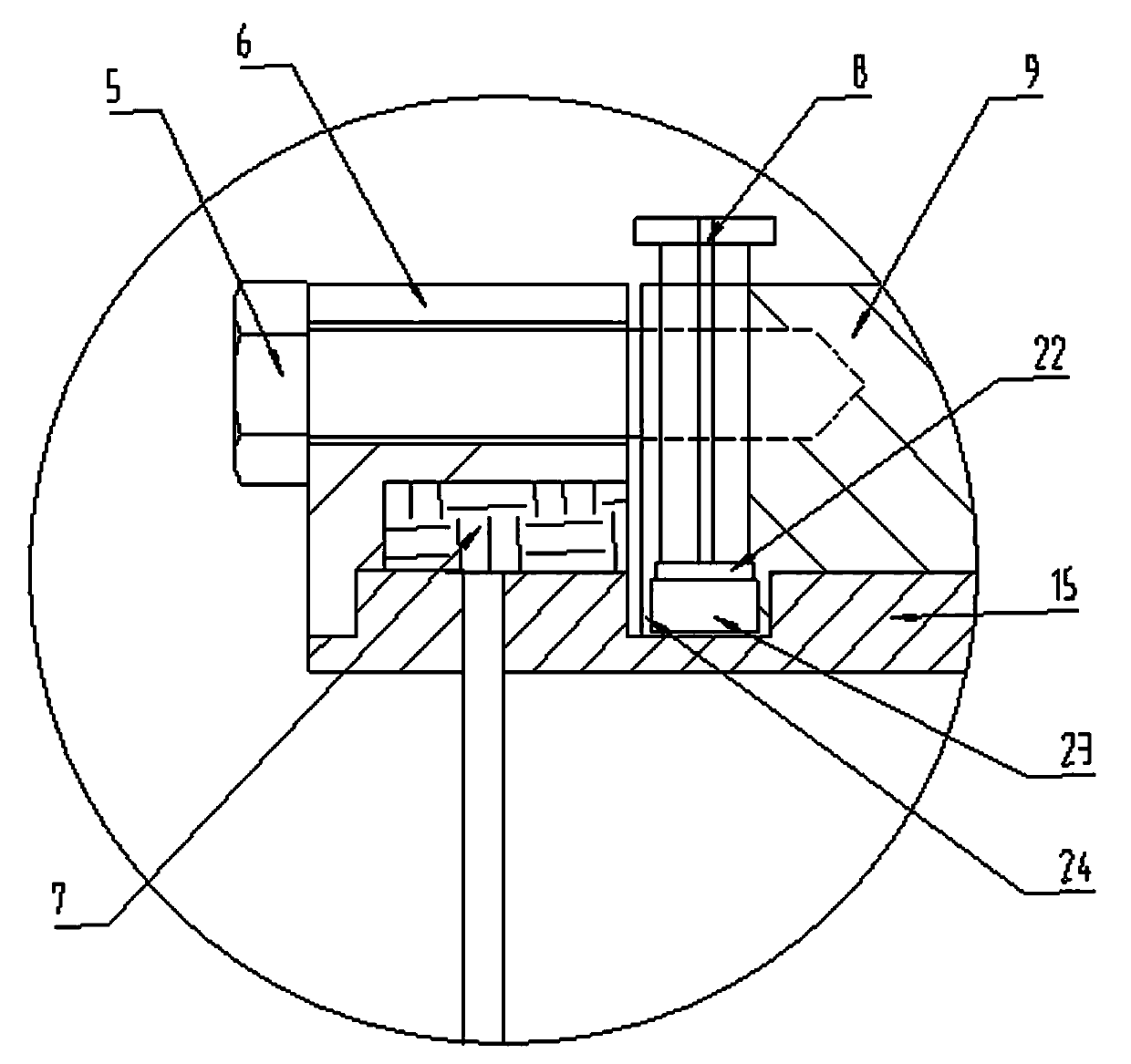

[0012] Such as figure 1 , figure 2 , image 3 As shown, a biomass dry distillation pyrolysis gasification device of the present invention includes a drum 15 placed obliquely above the frame 1, one end of the drum 15 is provided with a feed pipe 4, and the other end is provided with a material receiving chamber 20. An air outlet pipe 21 is arranged above the material chamber 20, and a slag outlet pipe 19 is arranged below the material receiving chamber 20. The outer wall of the drum 15 is also provided with a corresponding drum gear 10; A gearbox 3 is connected, and the gearbox 3 is connected with a transmission shaft 16, and the transmission shaft 16 is provided with a transmission shaft gear 17 correspondingly connected with the drum gear 10; 24. A number of rollers 23 are arranged in the card slot 24, and the rollers 23 are covered with a roller adjusting pressure rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com