Translation method of large tank-shaped equipment

A pot-shaped and equipment technology, applied in the field of overall movement of large-scale equipment, can solve the problems of large equipment quality and shape, difficult to translate, easy to roll, etc., and achieve the effect of shortening the laying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

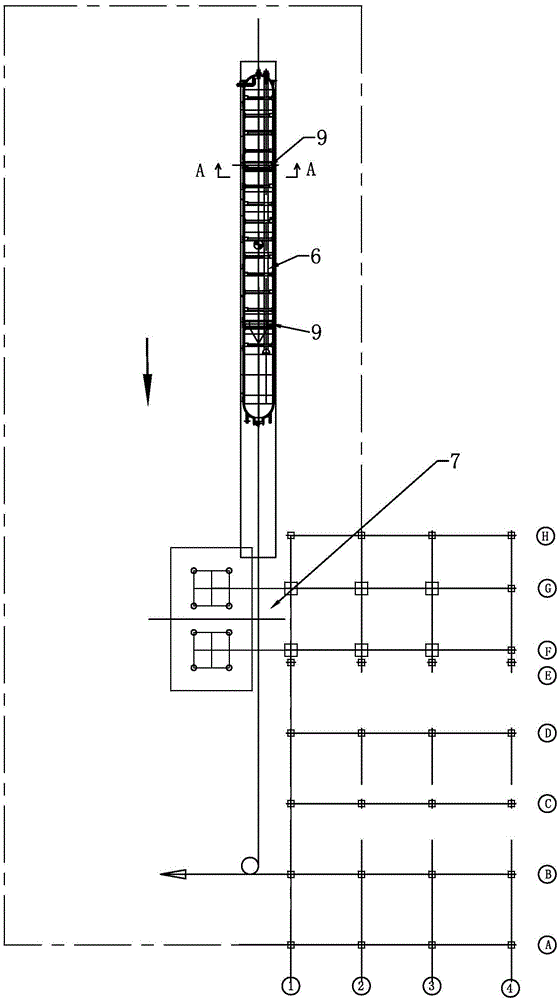

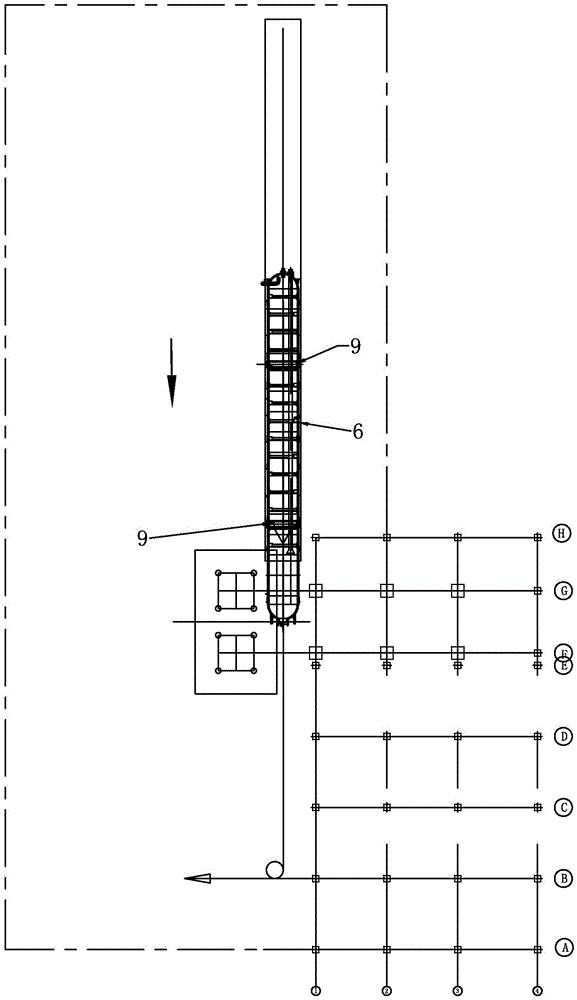

[0037] The translation method of the present invention will be specifically described below with the translation process of the urea synthesis tower.

[0038] The diameter of the urea synthesis tower that needs to be translated is nearly 4m, the length is 40m, and the weight of a single unit is more than 600 tons. Such as figure 1 As shown, the urea synthesis tower 6 is butt welded at 20 meters north of the urea frame, which is completed by the equipment manufacturer. After the equipment completes the assembly and welding work, it is necessary to translate the equipment from the assembly and welding position to the equipment's hoisting position 7, which is completed by hoisting on site.

[0039] The specific methods and steps are:

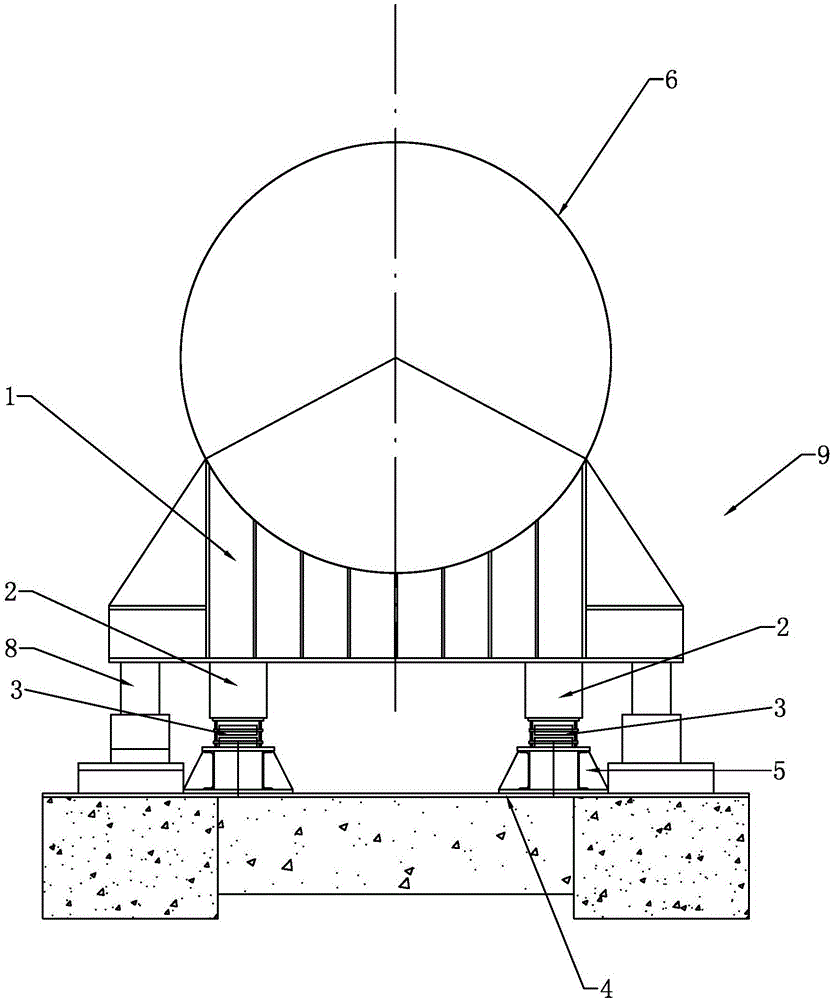

[0040] First, the road surface is leveled and hardened, and steel plates are laid on the road surface. The thickness of the steel plate 4 is 30 mm, the width is 1500 mm, the length is 8000 mm, and the number is 8 pieces. image 3 As shown, a wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com