Circulating treatment system for sludge drying carrier gas condensate water

A sludge drying and circulation treatment technology, which is applied in the waterway system, sewer system, water supply device, etc., can solve the problems of easy generation of odor, high discharge temperature, and high concentration of organic matter, and achieve odor mitigation, low investment, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed description and specific implementation of the embodiments of the present invention will be given below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but the protection scope of the present invention is not limited to the following examples.

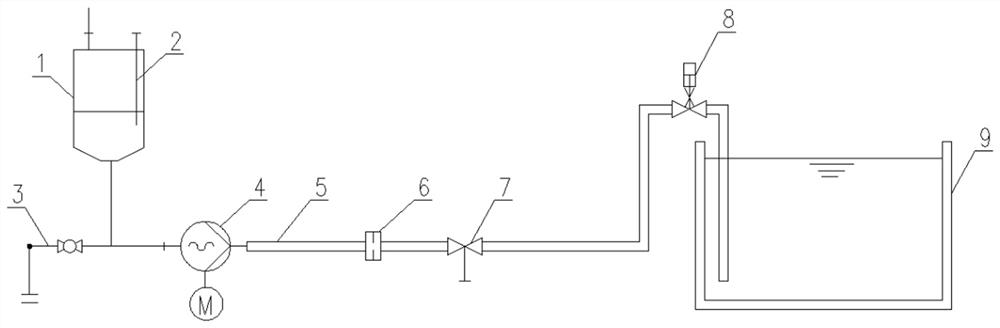

[0024] This example is selected from the sludge drying workshop of a sewage treatment plant in Shanghai. A recycling treatment technology for sludge drying carrier gas condensate, comprising a carrier gas condensate tank 1, a liquid level gauge 2, an emergency discharge port and a valve 3, a carrier gas condensate pump 4, a condensate discharge pipe 5, and a flow meter 6 , pipeline cleaning port 7, pipeline exhaust valve 8, present mud storage tank 9. Wherein, the carrier gas condensed water tank 1 is provided with a liquid level gauge 2, the bottom of the carrier gas condensed water tank 1 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com