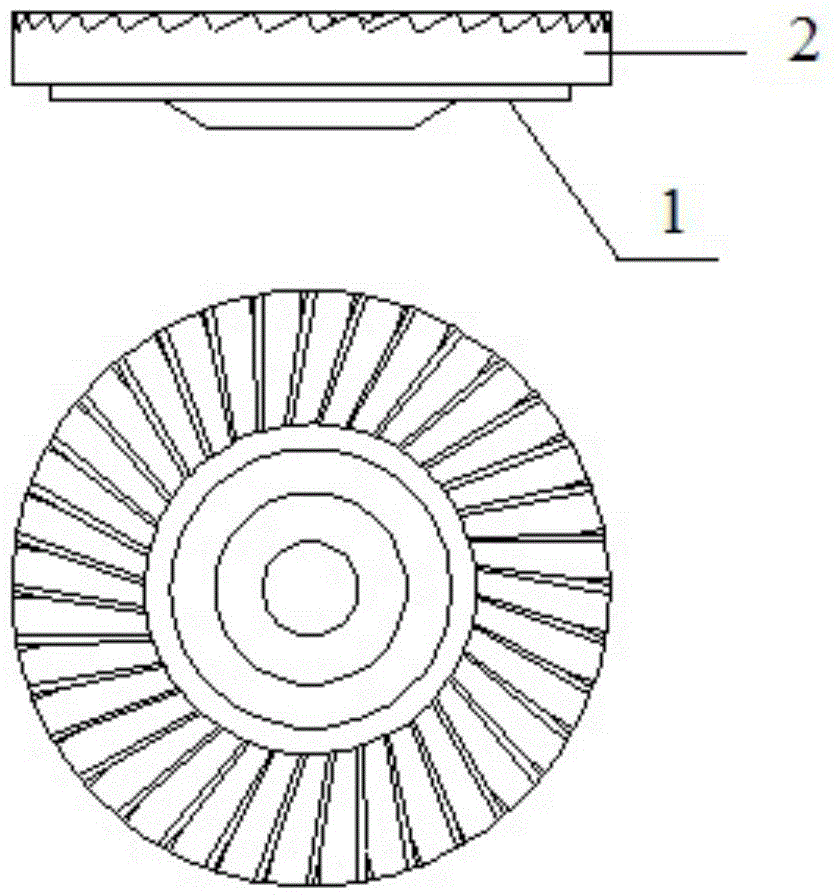

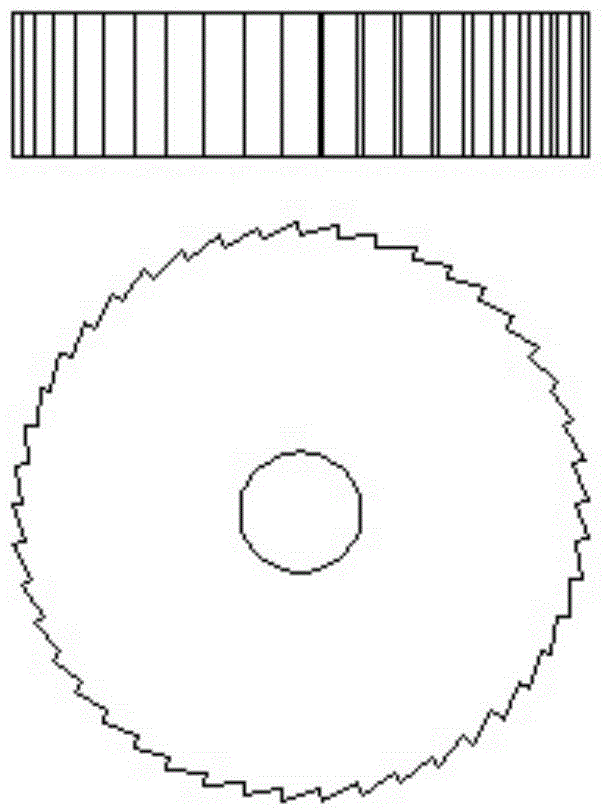

Preparation method for polishing wheel containing natural fibers and hollow microspheres

A hollow microsphere, natural fiber technology, applied in grinding/polishing equipment, wheels with flexible working parts, manufacturing tools, etc., can solve the problem of large surface temperature rise, adhesive failure, surface blackening, polishing Low efficiency and other problems, to achieve the effect of improving impact and bending strength, avoiding breaking and falling, and avoiding excessive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

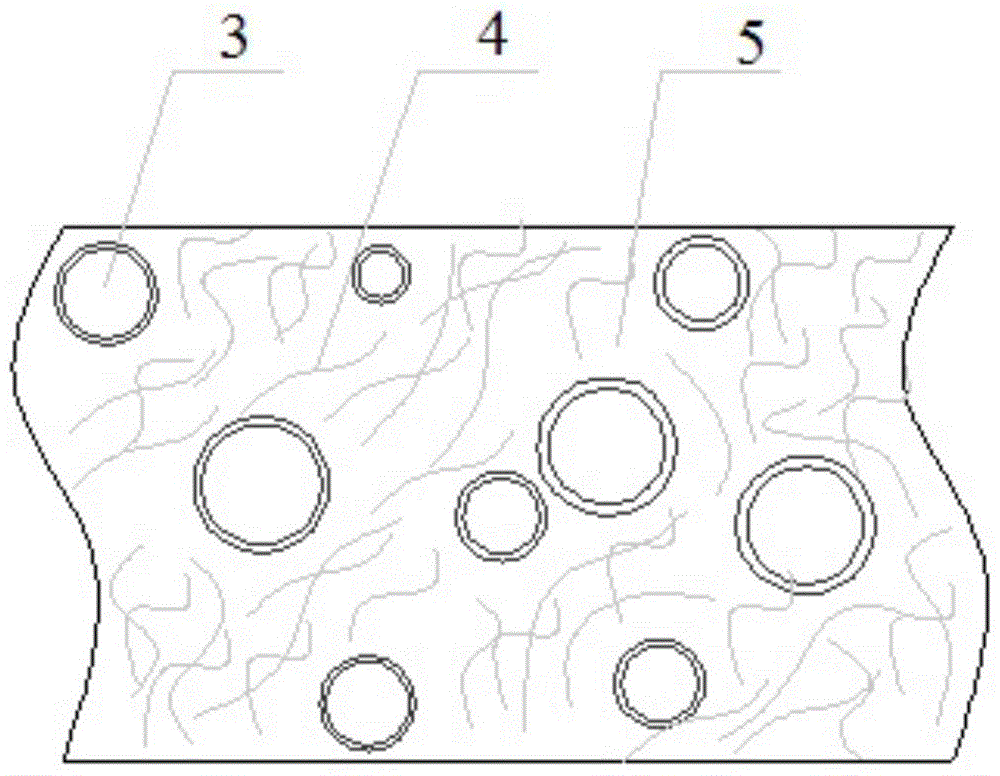

[0039] Example 1 (exploring the relationship between the volume ratio of hollow microspheres and natural fibers mixed with the polishing effect)

[0040] Recipe 1:

[0041]

[0042] 1 sample production

[0043]1.1 Mixing: according to the ratio of each style formula in formula 1, weigh the natural fibers in turn, (such as making a plane polishing wheel for flat polishing, use a fine number, and make a circumferential polishing wheel for circumferential polishing, then use a thick number), in the stirring state Then add the processed hollow microspheres to ensure uniform stirring; finally add the modified liquid phenolic resin in the stirring state and stir evenly. Throughout the mixing process, it is necessary to ensure that the mixing is uniform (no agglomeration or agglomeration).

[0044] 2.2 Pressing and solidification: According to the forming density of 0.6-0.7g / cm3, according to the volume of the polished wheel, calculate the weighing. Spread the weighed material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com