Numerical control opposite-direction slot milling machine

A groove milling machine and CNC sliding table technology, applied in the field of CNC machine tools, can solve the problems of long processing time, uneven force on single-sided milling parts, low degree of automation, etc., to achieve high processing stability and processing accuracy, and ensure quality. and cutting depth, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

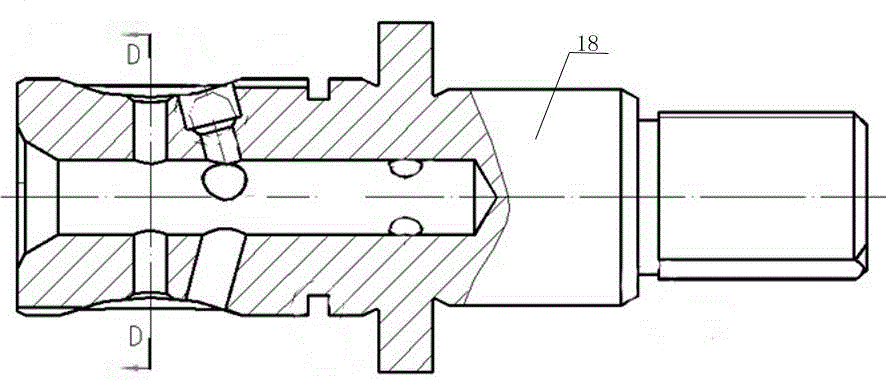

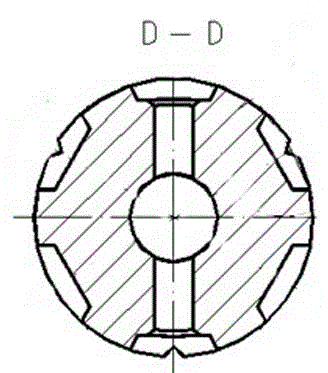

[0018] The invention as figure 1 shown.

[0019] Numerical control opposite slot milling machine, including machine tool base 1, the middle part of machine tool base 1 is provided with numerical control work platform 2, the clamp body 3 is provided on the numerical control work platform 2, the two sides of numerical control work platform 2 are respectively symmetrically provided with left and right numerical control sliders Tables 4, 5, left and right CNC sliding tables 4, 5 are respectively provided with left and right machine bodies 6, 7, and left and right milling heads 8, 8 are respectively arranged on the vertical guide rails of left and right machine bodies 6, 7 9, left and right milling heads 8,9 are connecting left and right drive motors 10,11 respectively.

[0020] Left and right machine bodies 6,7 and left and right milling heads 8,9 are locked by left and right locking devices 14,15 respectively.

[0021] Left and right lifting devices 12 and 13 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com