Preparation method for adsorbent for treating dye wastewater

A dye wastewater and adsorbent technology, which is applied in textile industry wastewater treatment, adsorption water/sewage treatment, chemical instruments and methods, etc., can solve the problems of no adsorbent, etc., and achieve simple wastewater treatment methods, easy scale, The effect of easy solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

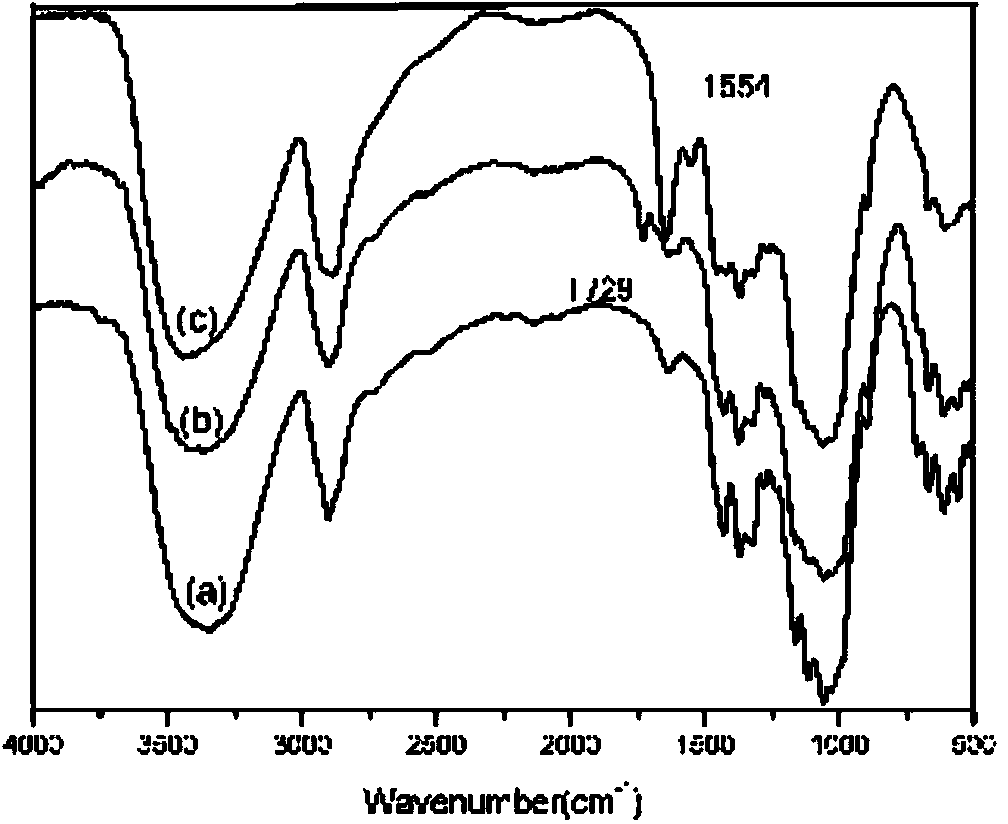

Method used

Image

Examples

Embodiment 1

[0023] Firstly, the bagasse fiber is pretreated: the bagasse fiber is dispersed and loosened for 5-10 minutes, boiled with deionized water for 2 hours, and then washed with ethanol and deionized water to remove impurities in the bagasse fiber. Then control the bath ratio to 1:30, place it in a NaOH solution with a mass concentration of 10% at room temperature and continuously stir at 100-200 rpm, activate for 60 minutes, wash until neutral, and dry for later use;

[0024] Control the bath ratio to 1:30, weigh 5g of activated bagasse fibers, place them in a sodium periodate solution with a concentration of 10g / L, react in the dark at 50°C for 120min, and wash thoroughly with deionized water to remove unreacted fibers. After the oxidizing agent is dried, the oxidized bagasse cellulose is obtained;

[0025] Control the bath ratio to 1:30, place the prepared oxidized bagasse fibers in an aqueous solution of hyperbranched polyamidoamine with a concentration of 20g / L, react at 60°C ...

Embodiment 2

[0027] Firstly, pretreat the bagasse fiber: disperse and loosen the bagasse fiber for 5-10 minutes, boil it with deionized water for 2 hours, and then wash it with ethanol and deionized water to remove impurities in the bagasse fiber. Then control the bath ratio to 1:30, place it in a NaOH solution with a mass concentration of 15% at room temperature, continuously stir at 100-200r / min, activate for 30 minutes, wash until neutral, and dry for later use;

[0028] Control the bath ratio to 1:30, weigh 5g of activated bagasse fibers, place them in a sodium periodate solution with a concentration of 15g / L, react in the dark at 50°C for 90min, wash thoroughly with deionized water to remove unreacted After the oxidizing agent is dried, the oxidized bagasse fiber is obtained;

[0029] Control the bath ratio to 1:50, place the prepared oxidized bagasse fibers in an aqueous solution of hyperbranched polyamidoamine with a concentration of 20 g / L, react at 70°C for 120 minutes, wash to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com