Manufacturing method for multistage buffering structure of running machine and multistage buffering structure

A cushioning structure and manufacturing method technology, which is applied in the field of treadmills, can solve problems such as difficult cushioning effects of treadmills, and achieve the effects of good cushioning and shock absorption, uniform force, and slow force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

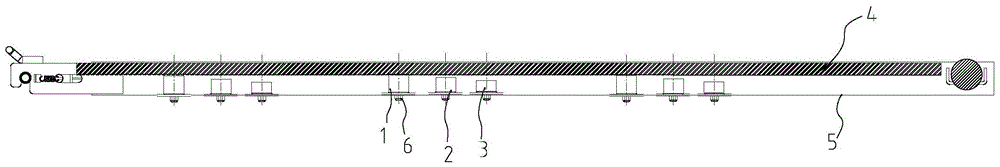

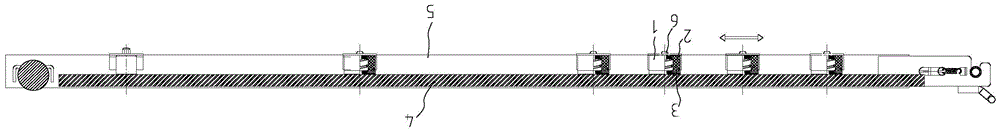

[0025] Such as figure 1 As shown, the treadmill multi-stage buffer structure manufactured according to the above-mentioned manufacturing method includes a running board 4 and a frame 5, a first buffer assembly 1, a second buffer assembly 2 and a third buffer assembly 3, and the first buffer assembly 1. Both the second buffer assembly 2 and the third buffer assembly 3 are arranged between the running board 4 and the frame 5, and the elasticity of the first buffer assembly 1 is greater than that of the second buffer assembly 2, the The elasticity of the second buffer component 2 is greater than that of the third buffer component by 3. The greater the elasticity, the greater the deformation and the smaller the elastic force. Therefore, the first cushioning component 1 has the largest elasticity, the largest deformation, and the smallest elastic force, and bears most of the buffering and shock-absorbing functions. Preferably, the first cushioning component 1 is made of spring, th...

Embodiment 2

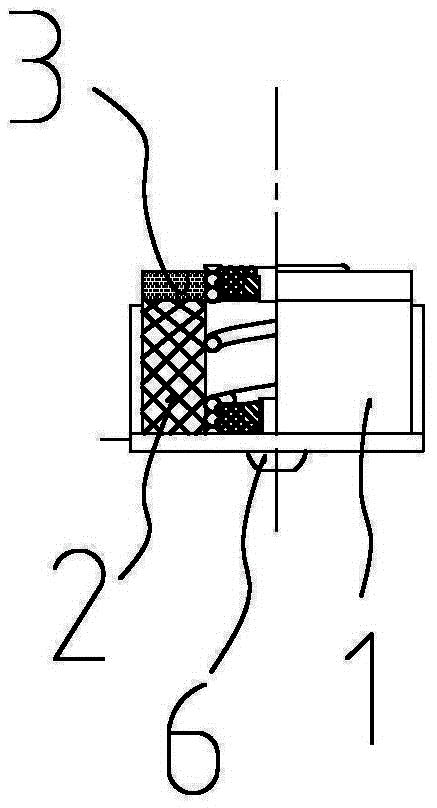

[0029] The difference between this embodiment and embodiment 1 is that the first buffer assembly 1 , the second buffer assembly 2 and the third buffer assembly 3 are integrated. Both ends of the first buffer assembly 1 are fixedly mounted on the running board 4 and the frame 5 through locking screws 6, and the second buffer assembly 2 is sleeved on the outer wall of the first buffer assembly 1, so The third buffer component 3 is superimposed on the upper end of the second buffer component 2 . And the upper surface of the third cushioning component 3 and the second cushioning component 2 superimposed is flush with the upper surface of the first cushioning component 1 .

[0030] The first buffer component 1 has the characteristics of small elastic force and high elasticity, and it bears most of the buffering effect. Compared with the first buffer component 1, the second buffer component 2 has larger elastic force and less elasticity, and its It not only has a certain cushioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com