Litsea cubeba oil microcapsule and preparation method thereof

A technology of litsea cubeba oil and microcapsules, which is applied in botany equipment and methods, edible seed preservation, chemicals for biological control, etc., can solve problems such as unsatisfactory use effects, and achieve good insect control performance and convenient use , effective use for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

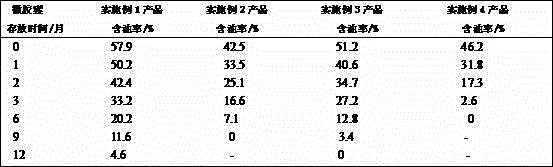

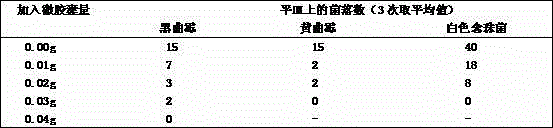

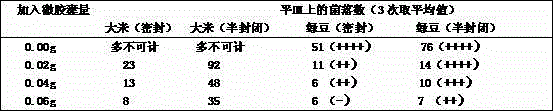

Embodiment 1

[0031] Take 2g of sodium alginate, add 65mL of water, stir, heat to 55°C, keep constant temperature, and make it into a uniform viscous liquid; then add 6g of litsea cubeba oil, stir evenly; finally account for 1% of the total amount of emulsion A The aqueous solution containing 2% Tween-80 was stirred thoroughly to obtain emulsion A, which was set aside.

[0032] Another 1.6g of chitosan and 8g of anhydrous calcium chloride were added to 150mL of water to make a solution, and the pH was adjusted to 5.5 with acetic acid to obtain coagulation bath B for use.

[0033]Drop the emulsion A into the coagulation bath B with a needle to obtain milky white microcapsules, store them sealed for 30 minutes, filter, collect the microspheres, dry in an oven at 50°C for 1 hour, wash with 5mL of petroleum ether, and obtain yellow granular products . The embedding rate of essential oil is 95.1%, and the oil content of microcapsules is 57.9%.

Embodiment 2

[0035] Take 2g of sodium alginate, add 98mL of water, stir, heat to 55°C, keep constant temperature, and make it into a uniform viscous liquid; then add 8g of litsea cubeba oil, stir evenly; finally account for 0.8% of the total amount of emulsion A The aqueous solution containing 1% Tween-80 was stirred thoroughly to obtain emulsion A, which was set aside.

[0036] Take another 6.2g chitosan and 3.8g anhydrous calcium chloride, add 185mL water to make a solution, adjust the pH to 5 with acetic acid, and obtain the coagulation bath B for use.

[0037] Drop emulsion A into solution B with a needle to obtain milky white microcapsules, store them sealed for 40 minutes, filter, collect the microspheres, dry in an oven at 50°C for 2 hours, wash with 8 mL of petroleum ether, and obtain yellow granular products. The embedding rate of essential oil is 85.7%, and the oil content of microcapsules is 42.5%.

Embodiment 3

[0039] Take 3g of sodium alginate, add 97mL of water, stir, heat to 60°C, keep the temperature constant, and make it into a uniform viscous liquid; then add 9g of litsea cubeba oil, stir evenly; finally account for 1% of the total amount of emulsion A The aqueous solution containing 2% Tween-80 was stirred thoroughly to obtain emulsion A, which was set aside.

[0040] Another 3.2g of chitosan and 4.8g of anhydrous calcium chloride were added to 152mL of water to form a solution, and the pH was adjusted to 6 with 1mol / L sodium hydroxide solution to obtain coagulation bath B for use.

[0041] Drop emulsion A into solution B with a needle to obtain milky white microcapsules, store them sealed for 50 minutes, filter, collect the microspheres, dry in an oven at 50°C for 2 hours, wash with 10 mL of petroleum ether, and obtain yellow granular products. The embedding rate of essential oil is 91.4%, and the oil content of microcapsules is 51.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com