Method for preparing antibacterial material of Ag magnetic carbon microspheres

An antibacterial material, carbon microsphere technology, applied in the fields of botanical equipment and methods, microsphere preparation, inorganic material magnetism, etc., can solve the problems of inability to recycle, low antibacterial performance, poor stability, etc., to achieve cost saving, easy Magnetic separation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

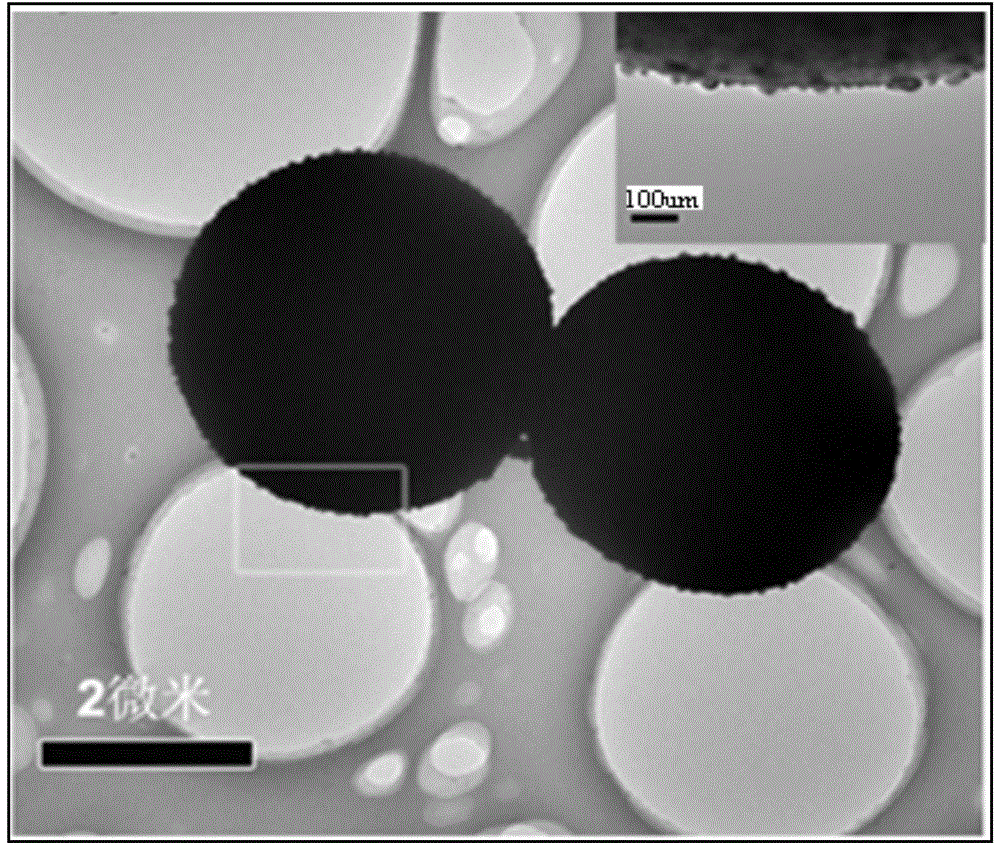

[0023] Specific embodiment one: a kind of method for preparing Ag magnetic carbon microsphere antibacterial material of the present embodiment is to finish according to the following steps:

[0024] 1. Weigh 1 to 3 parts of iron salt, 0.01 to 0.1 parts of surfactant, 0.5 to 2 parts of ammonia source, 1 to 3 parts of carbon source, 1 to 3 parts of silver source, 0.1 to 1 parts by weight. Parts of reducing agent and 20 to 50 parts of solvent;

[0025] 2. Fe 3 o 4 Preparation of magnetic fluid: first put the iron salt weighed in step 1 into a beaker, then add the ammonia source weighed in step 1 and 10 to 20 parts of the solvent weighed in step 1, and stir at 50°C to 90°C for 30 After ~300 minutes, add surfactant and continue to stir for 30 ~ 60 minutes, then cool to room temperature, you can get Fe 3 o 4 magnetic solution;

[0026] Three, the Fe obtained in step 2 3 o 4 The magnetic solution, the carbon source weighed in step 1 and 10-30 parts of the solvent weighed in st...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the carbon source described in Step 1 is one or more of glucose, starch, sucrose, and fructose mixed in any ratio. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the surfactant described in step one is cetyl trimethyl ammonium bromide, cetyl dimethyl benzyl bromide Ammonium, cetyl ethoxylate dimethyl octyl ammonium chloride, lauryl ethoxylate dimethyl ammonium chloride, octylphenol ethoxylate dimethyl decane ammonium bromide, octylphenol polyoxyethylene ether dimethyl decyl ammonium chloride, cetyl alcohol polyoxyethylene ether dimethyl octyl ammonium chloride, sodium lauryl sulfate, lauryl Sodium Alkyl Sulfonate, Sodium Cetyl Benzene Sulfonate, Sodium Octadecyl Sulfate, Sodium N-Oleoyl Polypeptide, Sodium Sulfate of Fatty Alcohol Polyoxyethylene Ether, Sodium Fatty Alcohol Polyoxyethylene Ether Sulfosuccinic Acid Disodium Monoester, Lauryl Dimethyl Amine Oxide, Coco Alkyl Dimethyl Amine Oxide, Lauryl Dimethyl Amine Oxide, Lauryl Dihydroxyethyl Amine Oxide, Tetradecyl Dihydroxy Amine Oxide Ethyl amine oxide, hexadecyl dihydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com