Cap assembly with novel structure and cylindrical battery using same

A technology of cylindrical battery and cap assembly, applied in the direction of cylindrical shell battery/battery, structural parts, battery, etc., to prevent fire and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Now, referring to the accompanying drawings, preferred embodiments of the present invention will be described in detail. It should be noted, however, that the scope of the present invention is not limited by the illustrated embodiments.

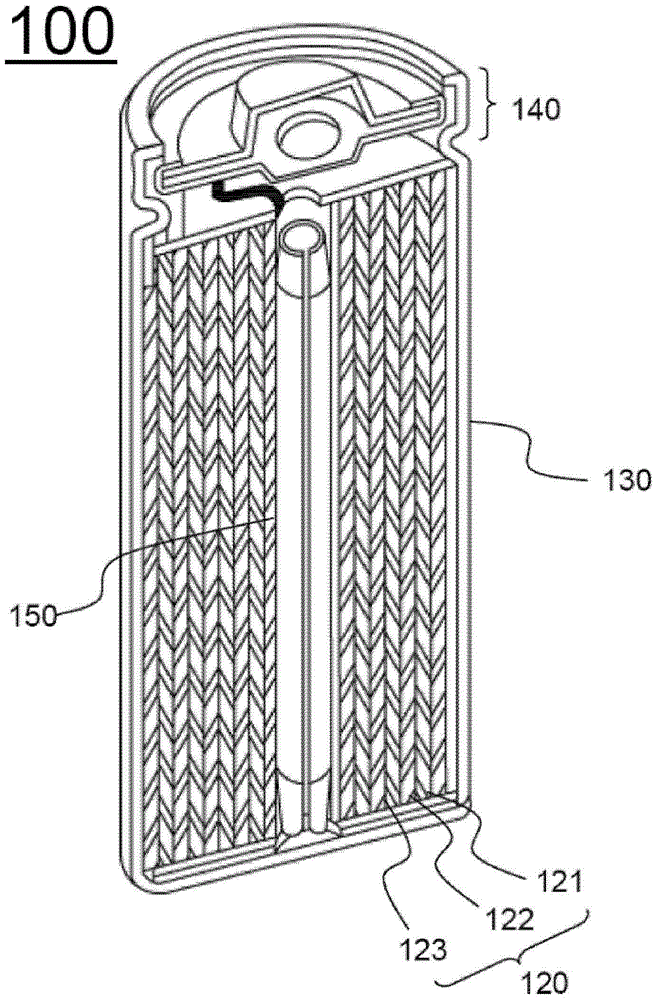

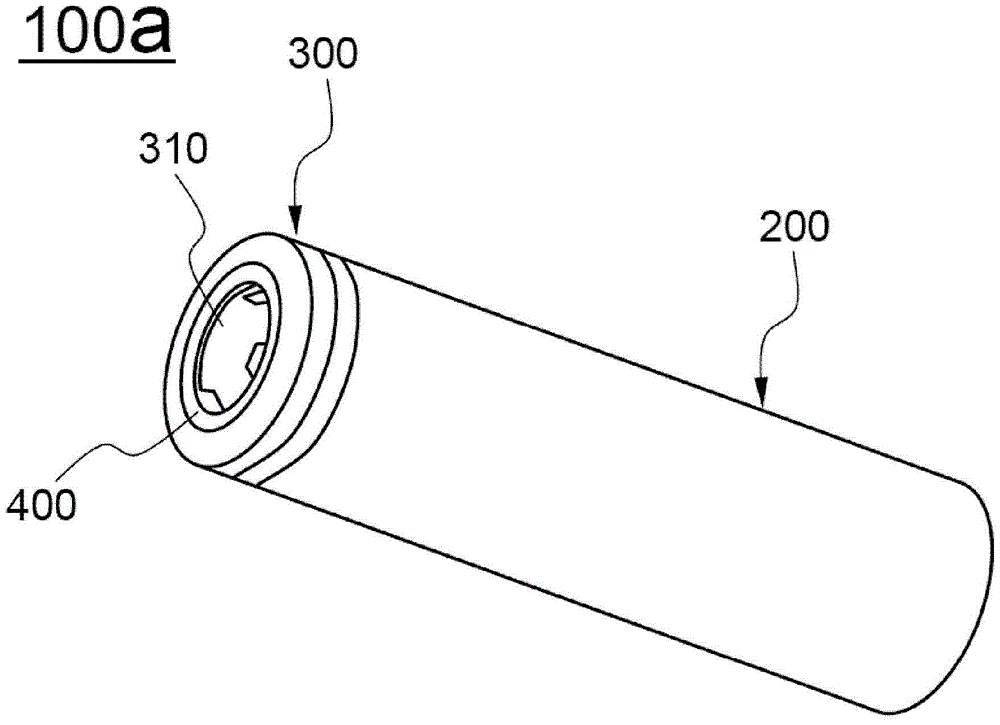

[0061] image 3 is a perspective view showing a cylindrical battery according to an embodiment of the present invention, and Figure 4 yes image 3 exploded view.

[0062] Referring to these drawings, a cylindrical battery 100a according to an embodiment of the present invention is manufactured by inserting a jelly roll (not shown) into a container 200, injecting an electrolyte into the container 200, and placing the cap Assembly 300 is mounted to the open upper end of container 200 . In addition, the insulating member 400 is positioned at the upper end of the cap assembly 300 and pressed by the tube 410 to insulate the cathode and the anode.

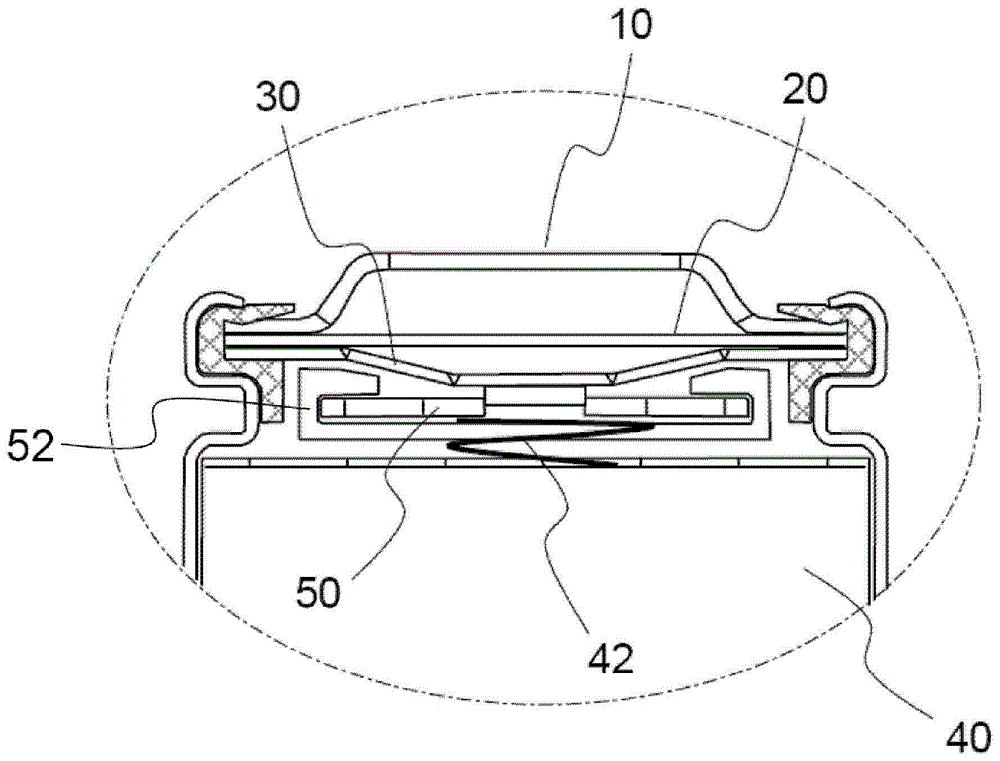

[0063] Figure 5 yes image 3 The partial enlarged view of Figure 6 yes image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com