Lifting device, semiconductor chip production metal etching equipment and method

A lifting device and lifting mechanism technology, which is applied in semiconductor/solid-state device manufacturing, transportation and packaging, discharge tubes, etc., to improve the reliability of the action, eliminate lost steps, and maintain uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable your examiners to have a further understanding and understanding of the purpose, features and effects of the present invention, the following detailed descriptions are as follows with the accompanying drawings.

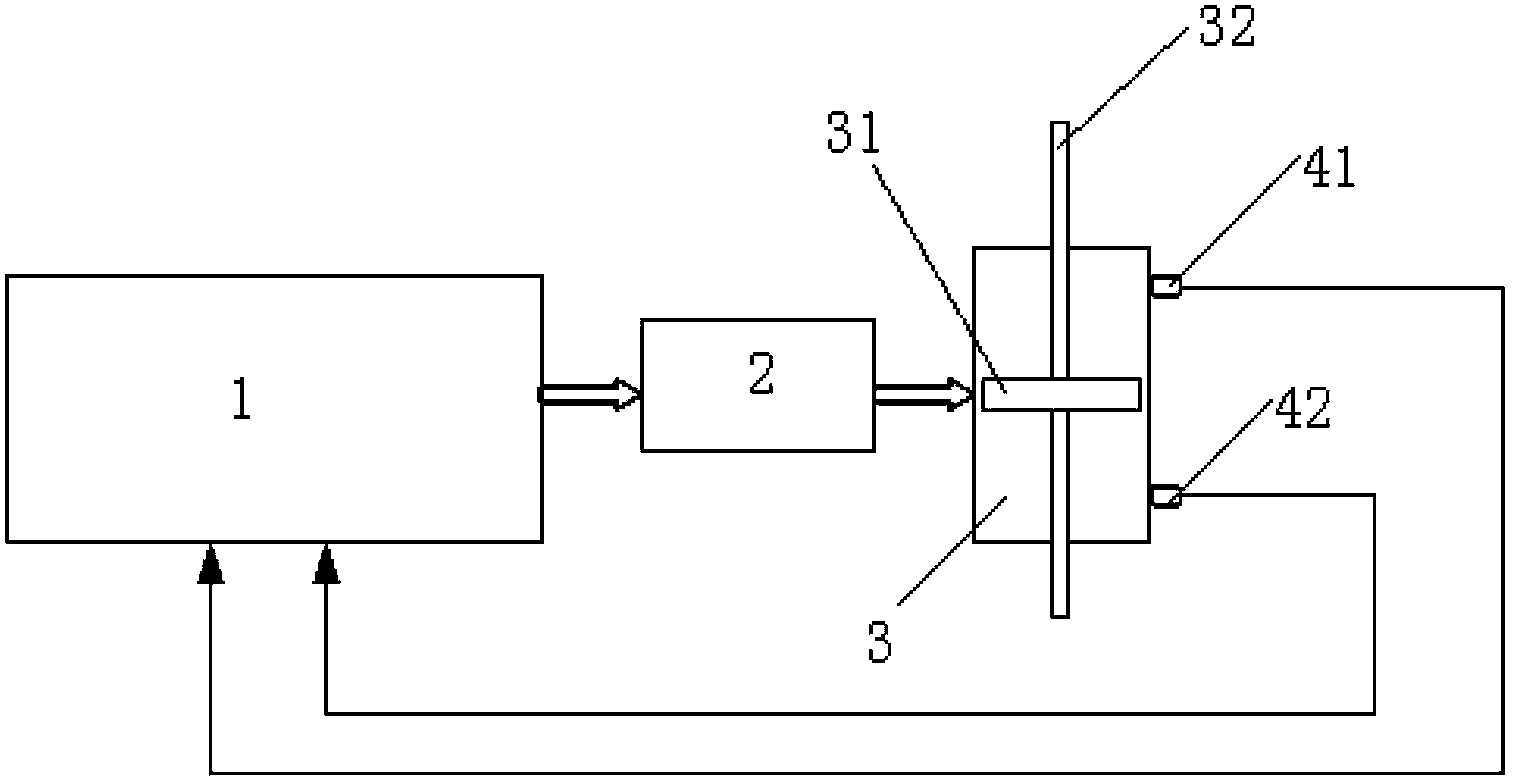

[0039] Such as figure 1 As shown, the lifting device of the present invention includes a control unit 1, a solenoid valve 2, a cylinder 3, and an upper limit sensor 41 and a lower limit sensor 42; the cylinder 3 includes a piston 31 and a piston rod 32; its working principle is, The control unit 1 sends a voltage signal to the solenoid valve 2 to drive the solenoid valve 2 to act, thereby causing the piston 31 of the cylinder 3 to move upward or downward. When the upper limit sensor 41 or the lower limit sensor 42 detects that the piston 31 has moved in place, the The control unit 1 sends a feedback signal. Wherein the piston rod 32 can be connected with other components to drive the action.

[0040] Such as figure 2 As shown, the metal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com