Boiler combustion and waste heat recovery comprehensive monitoring intelligent control system

An intelligent control system and comprehensive monitoring technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems affecting boiler combustion efficiency, carbon monoxide leakage, difficult automation information systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

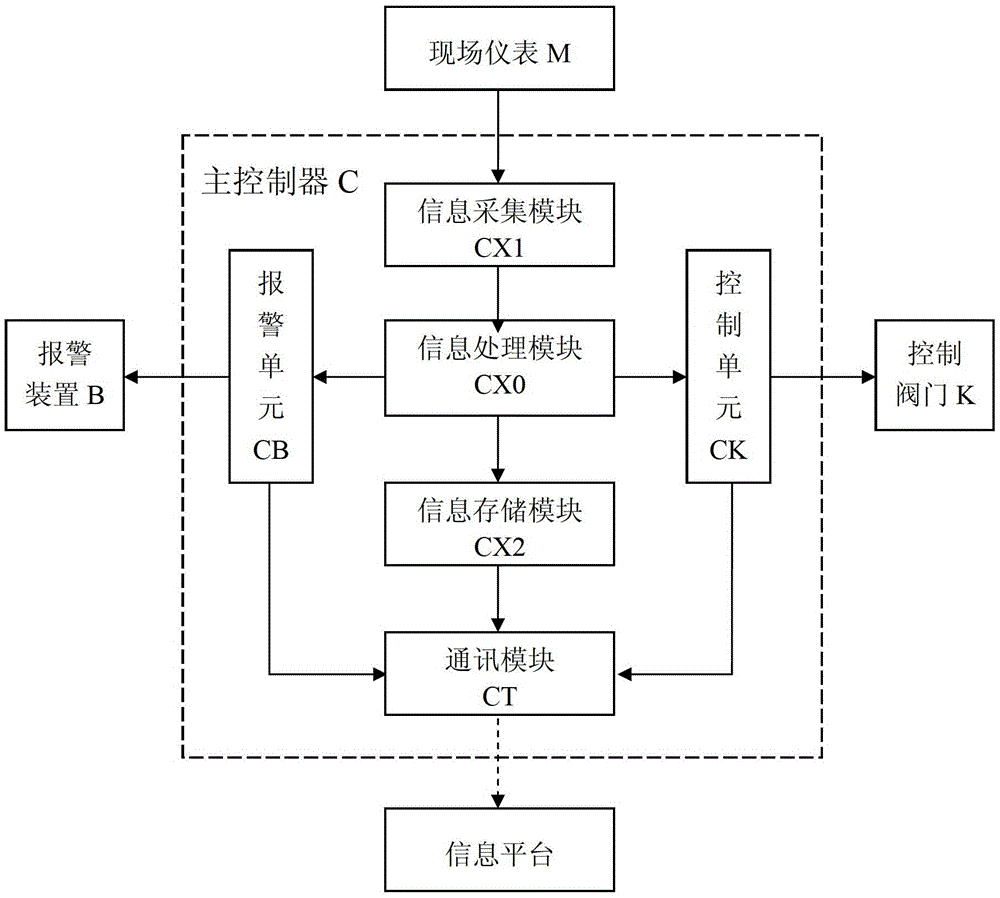

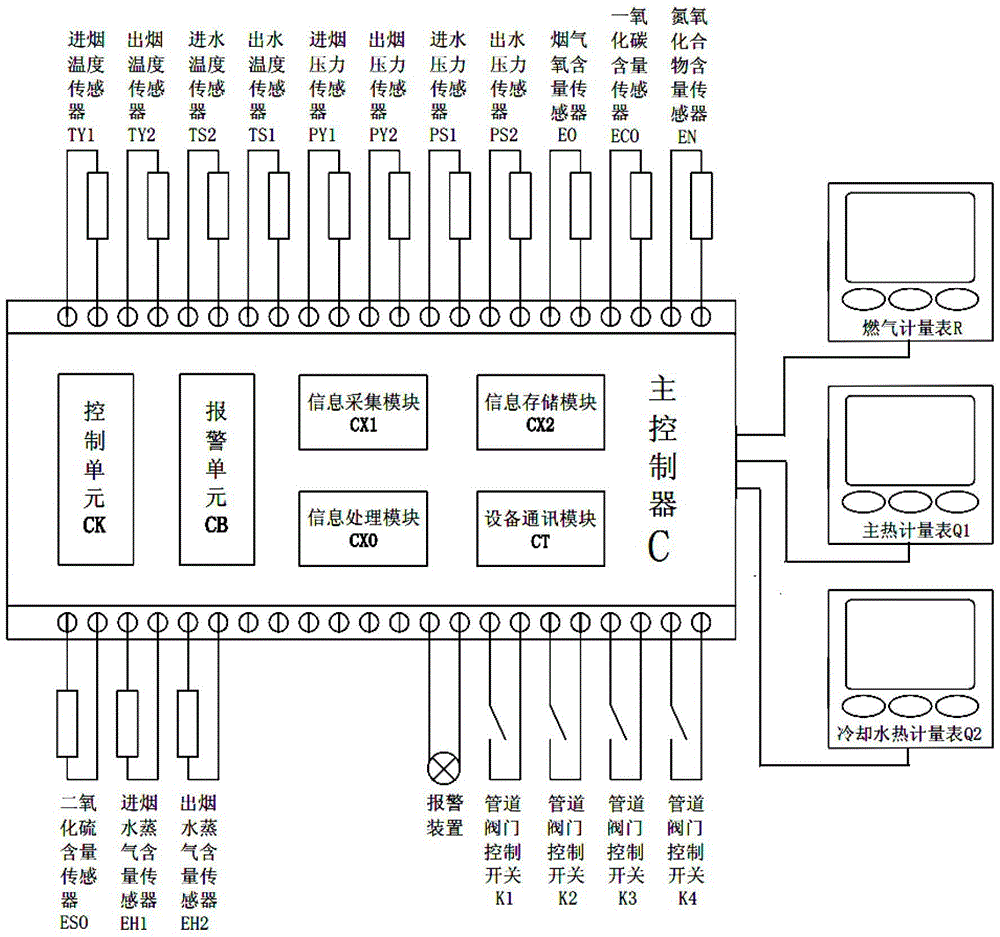

[0013] see figure 1 and figure 2 , the boiler combustion and waste heat recovery comprehensive monitoring intelligent control system of the present invention includes a field instrument M installed in the boiler pipeline and smoke exhaust system, an alarm device B, a control valve K, a main controller C and an information platform. Field instrument M includes inlet water temperature sensor TS2, outlet water temperature sensor TS1, inlet water pressure sensor PS1, outlet water pressure sensor PS2, gas meter R, main heat meter Q1, cooling water heat meter Q2, inlet smoke temperature sensor TY1, Smoke outlet temperature sensor TY2, smoke inlet pressure sensor PY1, smoke outlet pressure sensor PY2, flue gas oxygen content sensor EO, flue gas carbon monoxide content sensor ECO, flue gas nitrogen oxide content sensor EN, flue gas sulfur dioxide content sensor ESO, The water vapor content of the incoming smoke is EH1 and the water vapor content of the outgoing smoke is EH2. Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com