Carbon deposition prevention gasifier

A technology for gasification furnaces and carbon deposition prevention, which is applied to household furnaces/stoves, granular/powdered fuel gasification, and combustion methods. Poor practicability and other problems, to achieve the effect of good carbon removal effect, high practical value, and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

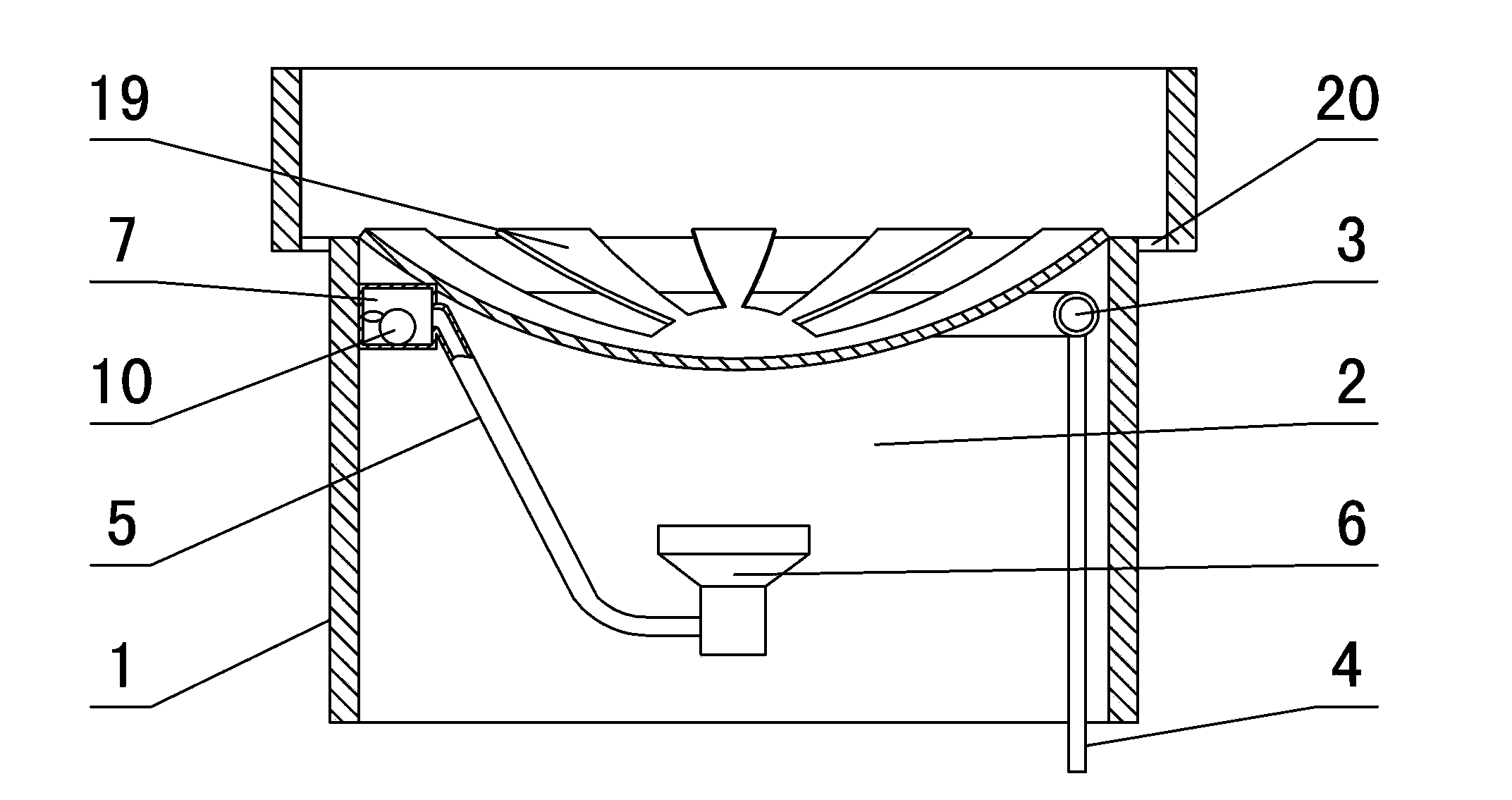

[0027] in such as figure 1In the shown embodiment 1, an anti-carbon deposition gasification furnace includes a fuel delivery pipe 4 and a gasification furnace core. The gasification furnace core includes a furnace core body 1 with a hollow structure. The furnace core wall is provided with annularly distributed ventilation slots 20 between the upper and lower layers of the furnace core wall. The hollow part in the furnace core body is the furnace 2, the top of the furnace is provided with a deflector 19, the position above the furnace close to the inner wall of the furnace core is provided with a circular vaporization tube 3, one end of the vaporization tube is connected to the fuel delivery pipe 4, and the other end is The vaporization nozzle 6 arranged at the lower part of the furnace is connected through the steam outlet pipe 5. The vaporization pipe, the steam outlet pipe and the vaporization nozzle constitute the air flow channel of the gasification furnace. The carbon ch...

Embodiment 2

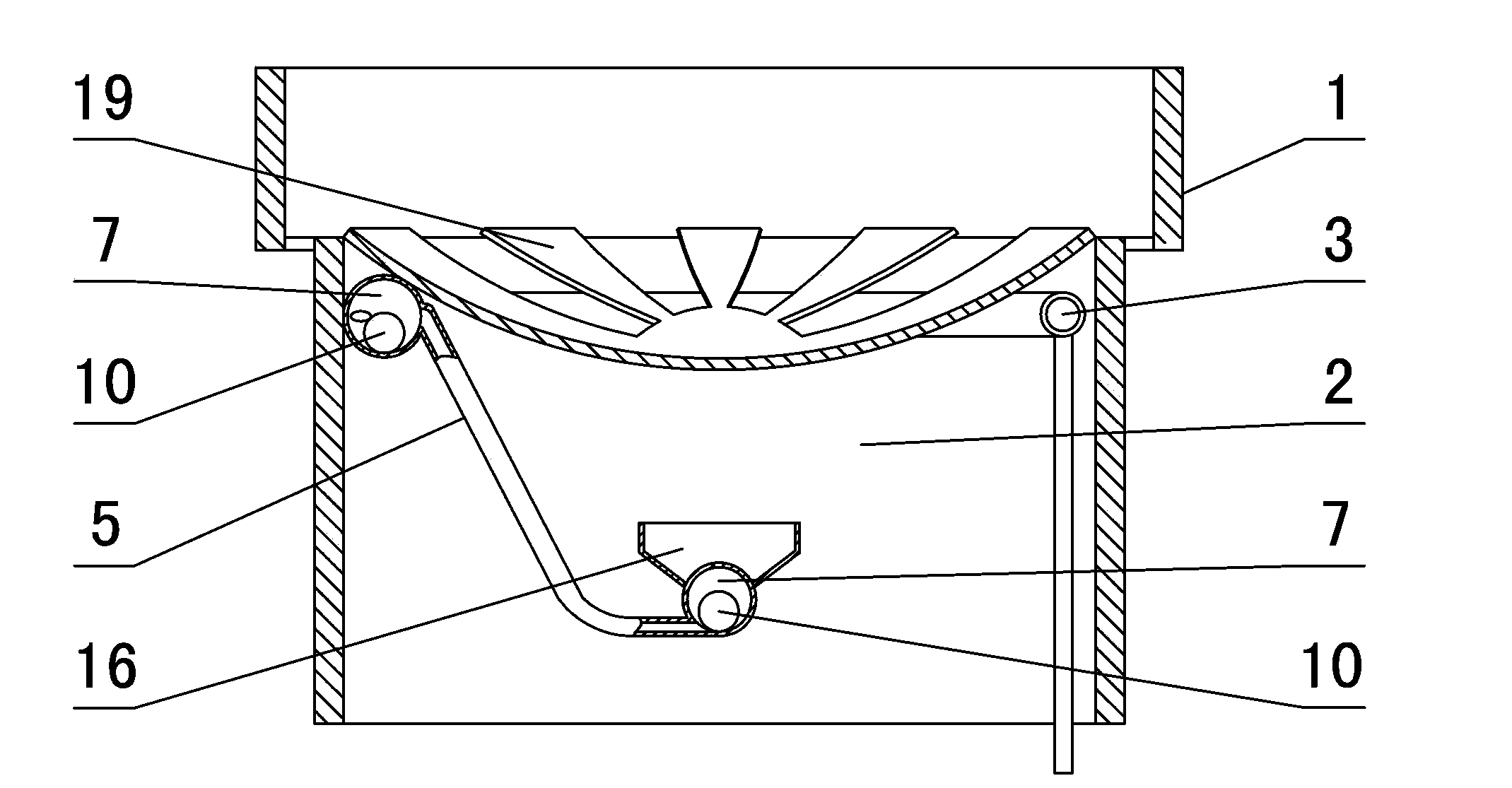

[0029] Its decarbonization cavity of the anti-carbon deposition gasification furnace of embodiment 2 is spherical (see Figure 4 ), set at the connection between the steam outlet pipe and the vaporization nozzle, the carbon removal chamber and the vaporization nozzle are integrally structured, the upper ignition bowl 16 is arranged above the vaporization nozzle, and the gas outlet on the carbon removal chamber is set at the decarbonization nozzle The top of the carbon cavity is where the bottom of the firing bowl is located (see figure 2 ), and the rest are the same as in Example 1.

Embodiment 3

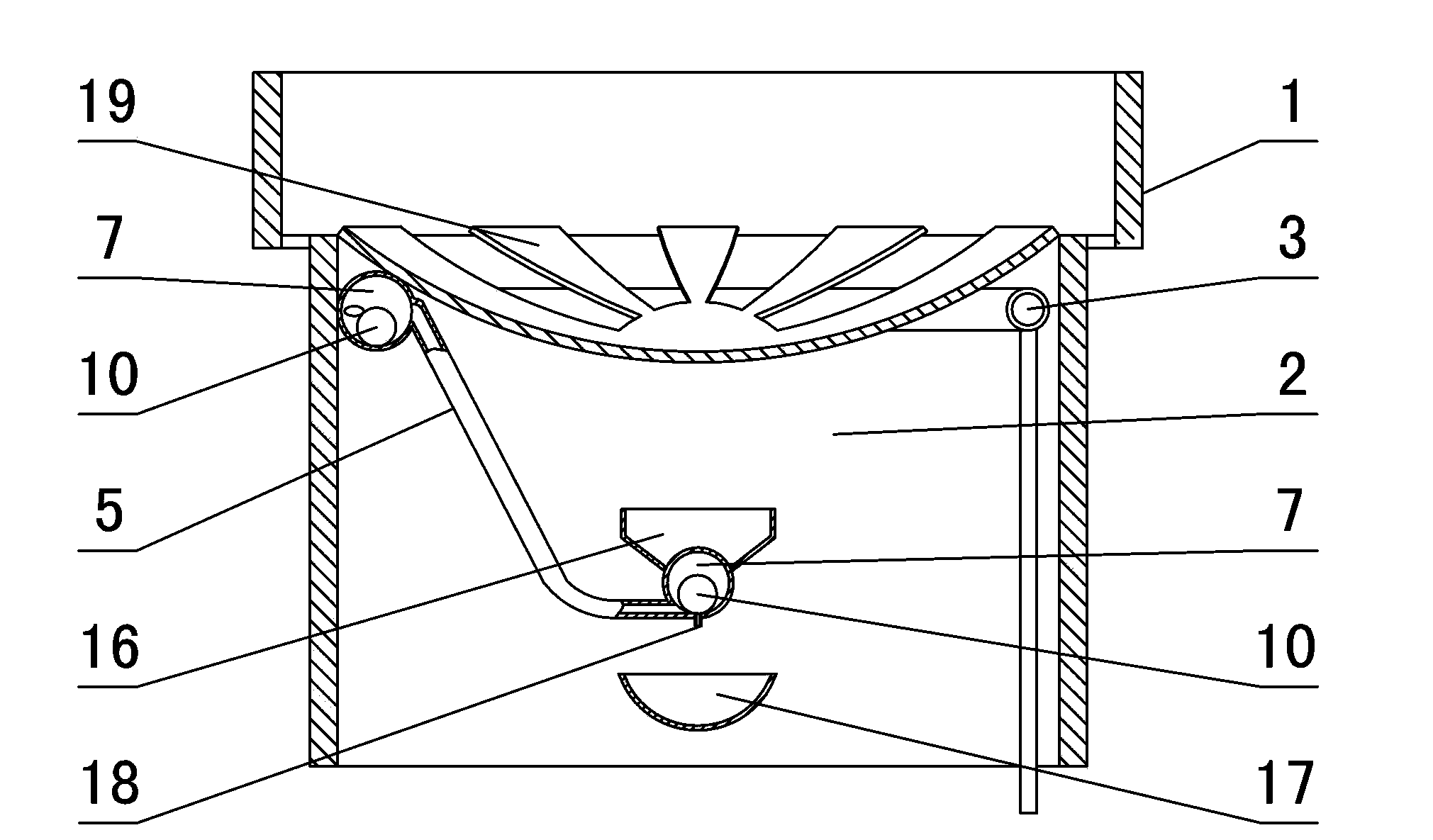

[0031] In the anti-carbon deposition gasification furnace of embodiment 3, the connection between the vaporization pipe and the steam outlet pipe and the connection between the steam outlet pipe and the vaporization nozzle are all equipped with a carbon removal chamber, which is arranged at the connection between the steam outlet pipe and the vaporization nozzle. The bottom is provided with a lower firing bowl 17, and the bottom of the carbon removal chamber at the junction of the steam outlet pipe and the vaporization nozzle is provided with an air leakage port 18 with an opening pointing to the downward firing bowl. The cross-sectional area of the air leakage port is smaller than the gas outlet (see image 3 ), and the rest are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com