Air-casting high-performance polymer concrete inflatable inspection type small water cellar, construction method, application and special inflatable mold

A construction method and high-performance technology, applied in gas production bioreactors, buildings, building types, etc., can solve problems such as increased construction difficulty, inability of construction personnel to stand, and difficulty in plastering, so as to improve accuracy and improve detection sealing. Air efficiency, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

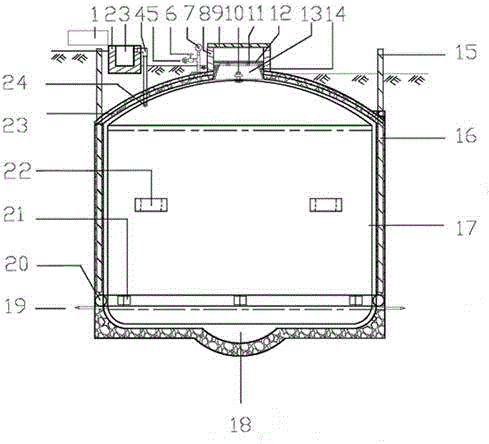

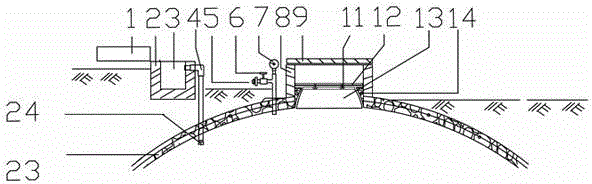

[0047] Embodiment 1: A small water cellar of gas-casting polymer concrete inflatable inspection type, including a concrete cellar body 16, cellar mouth cover 9, cellar mouth neck 8, drainage channel 1, water accumulation and sedimentation tank 3, water inlet 2, PVC The water inlet pipe 4; the pit neck 8 is barrel-shaped, the concrete pit body 16 is spherical, and is located directly above the arc-shaped arch cover 23 of the concrete pit body 16, and the pit mouth cover 9 is covered on the pit neck 8 for covering The pit mouth neck 8 is located on the ground above the concrete pit body 16 and the drainage channel 1 is excavated. The water outlet of the accumulated water sedimentation tank 3 is horizontal to the upper part of the pit neck 8, and one end of the PVC water inlet pipe 4 is used to connect the accumulated water sedimentation tank 3 The other end of the water outlet is connected to the concrete cellar body 16, and there is a positive "eight"-shaped air sealing port 14 ...

Embodiment 2

[0048] Embodiment 2: The concrete pit body 16 described in Embodiment 1 is an irregular cube, and the rest are the same.

Embodiment 3

[0049] Embodiment 3: The middle part of the concrete cellar body 16 described in Embodiment 1-2 is barrel-shaped, and the top is an upwardly curved arc-shaped arch cover 23. The arc-shaped arch cover 23 has a built-in reinforcing steel mesh, and the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com