Embroidery production method and embroidered objects

A production method and embroidery technology, applied in the field of embroidery, can solve the problems of embroidery pattern offset, pre-production, offset, etc., and achieve the effects of saving manpower and cost, accelerating mass production speed, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

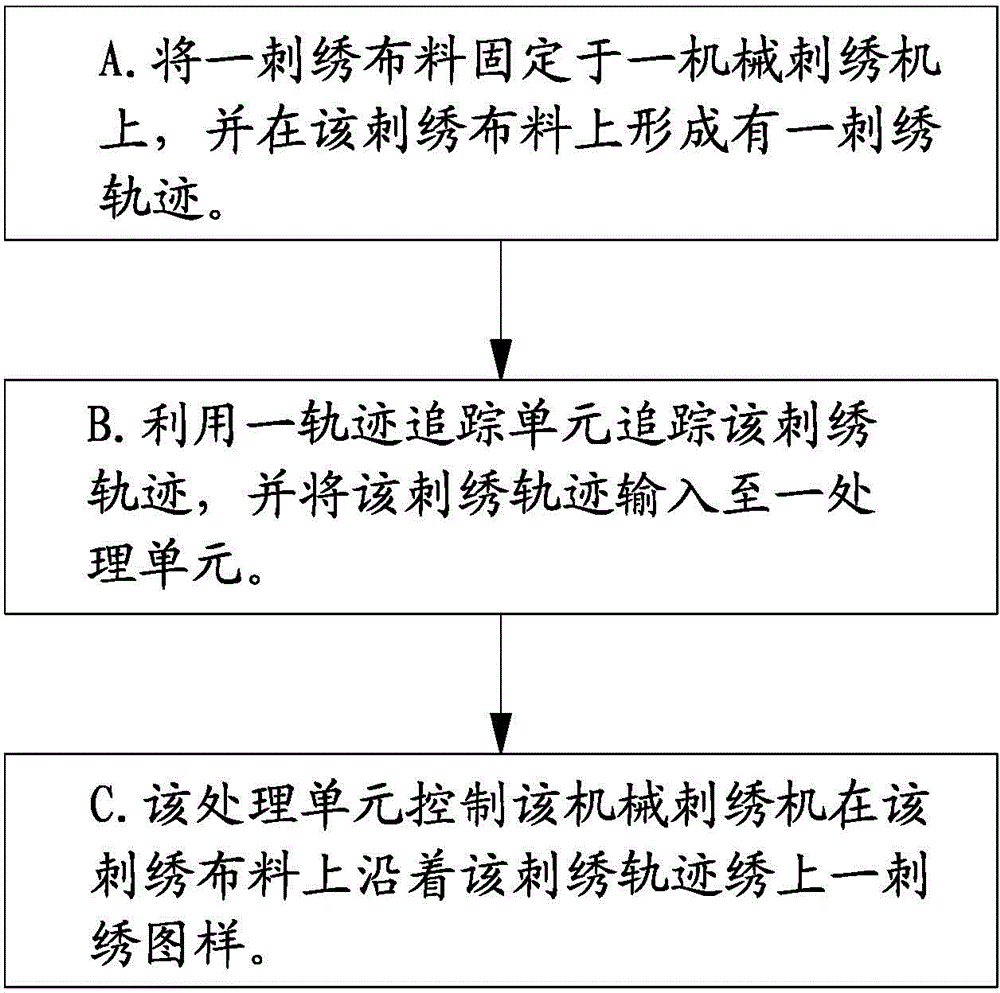

[0037] Based on the above technical features, the main functions of the embroidery production method of the present invention and the embroidered objects can be clearly presented in the following embodiments.

[0038] see figure 1 Shown, at first introduce the device that implements the inventive method, it comprises:

[0039] A mechanical embroidery machine 1 is used to fix an embroidery cloth 2 and perform mechanical embroidery on the embroidery cloth 2; a track tracking unit 3 is used to track an embroidery track 21 made on the embroidery cloth 2. Trajectory tracking unit 3 is arranged on different embroidery implements as required, such as embroidery needle 11, roller 12 or laser laser 13, etc., and this trajectory tracking unit 3 can use light-sensing trajectory tracking device 31, color sensing device, CCD image capture Any one of the light sensing device 32 or the scanner 33 of the device, the light pen 321 and the sensor 322. The above-mentioned numbered trajectory t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com