Method for preparing Soraean gum and application thereof in water treatment

A solar glue and water treatment technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of refractory secondary pollution, strong neurotoxicity, etc., and achieve Low cost, clear ingredients, fast flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

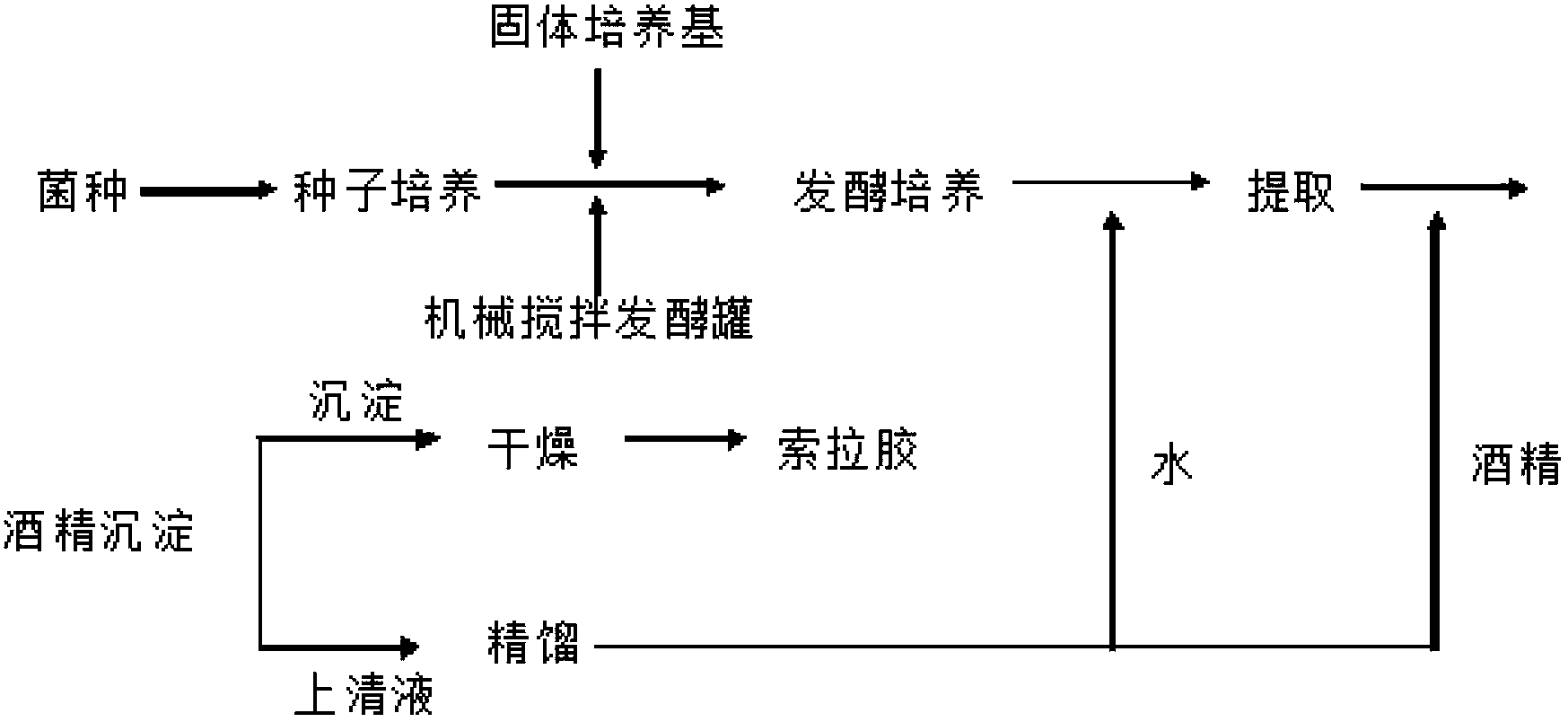

[0025] Such as figure 1 As shown, prepare the culture medium.

[0026] Seed culture solution: NaH 2 PO 4 0.25g, KNO 3 1.5g, CaCl 2 0.05g, MgCl 2 0.15g, FeSO 4 ·7H 2 O 0.004g, MnSO 4 0.001g, ZnCl 2 0.004g, sucrose 20g, H 2 O 1000 mL, pH7.2, fermentation culture solution Add 30g NaCl to the seed culture solution, heat the seed culture solution at 110°C for 30 minutes to sterilize, add 100 μL plate colony liquid to the seed culture solution cooled to 30°C, and incubate at 28°C Ferment for 18 hours to form seed liquid, wash the brewer's grains twice with water, add 15mL of fermentation culture liquid, and then add 5% seed liquid, ferment at 28 ℃ for 48h, add 20mL of distilled water to the fermentation bottle to wash the brewer's grains twice, and collect supernatant, inject more than twice the volume of ethanol into the hair supernatant, and vacuum-dry at 50°C to obtain the crude product of bioflocculant sola gum.

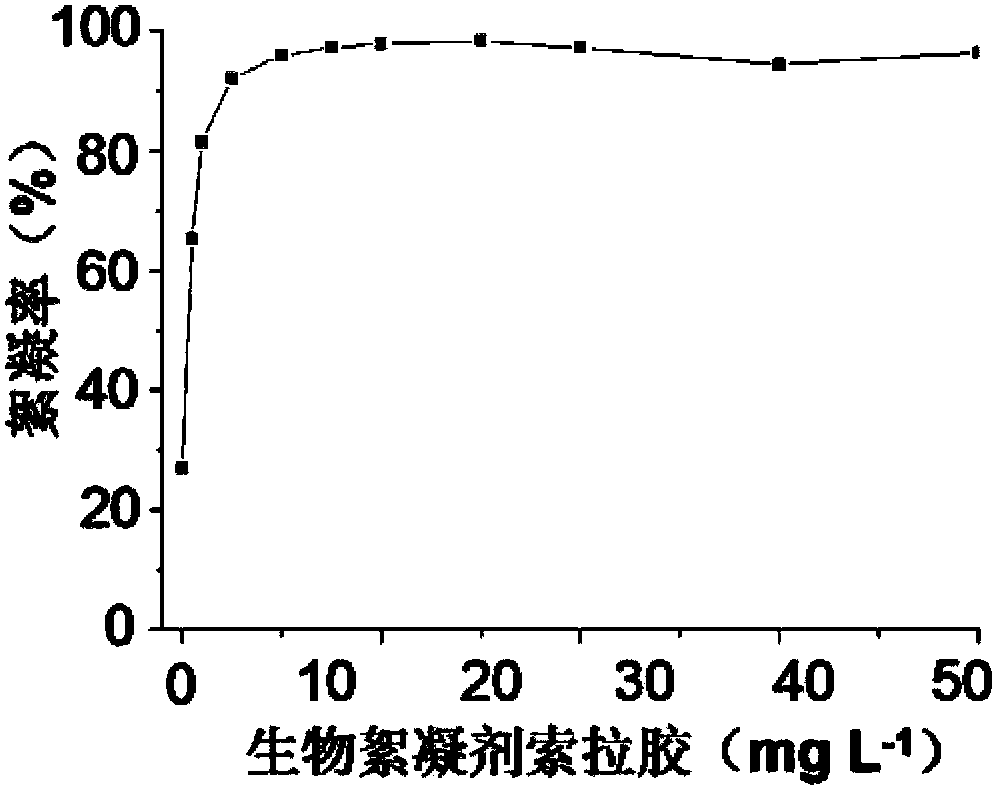

[0027] Detection of flocculation effect: take 1...

Embodiment 2

[0033] Such as figure 2 As shown, prepare the culture medium.

[0034] Seed culture solution: NaH 2 PO 4 0.5g, KNO 3 2.5g, CaCl 2 0.07g, MgCl 2 0.2g, FeSO 4 ·7H 2 O 0.006g, MnSO 4 0.002g, ZnCl 2 0.006g, sucrose 40g, H 2 O 1000 mL, pH8.0, fermentation culture solution Add 30g NaCl to the seed culture solution, heat the seed culture solution at 110°C for 30 minutes to sterilize, add 100 μL plate colony liquid to the seed culture solution cooled to 32°C, and incubate at 28°C Ferment for 20 hours to form seed liquid, wash the brewer's grains twice with water, add 15mL of fermentation culture liquid, then add 8% seed liquid, ferment at 28 ℃ for 48h, add 20mL of distilled water to the fermentation bottle to wash the brewer's grains twice, collect supernatant, inject more than twice the volume of isopropanol into the hair supernatant, and vacuum-dry at 50°C to obtain the crude product of bioflocculant Sola gum.

[0035] Detection of flocculation effect: Take 1000mL ...

Embodiment 3

[0038] Such as figure 1 As shown, prepare the culture medium.

[0039] Seed culture solution: NaH 2 PO 4 2g, KNO 3 3g, CaCl 2 0.07g, MgCl 2 0.25g, FeSO 4 ·7H 2 O 0.01g, MnSO 4 0.002g, ZnCl 2 0.008g, 30g sucrose, H 2 O 1000 mL, pH 6.0, fermentation culture solution Add 40g NaCl to the seed culture solution, heat the seed culture solution at 121°C to sterilize for 15 minutes, add 150 μL plate colony liquid to the seed culture solution cooled to 37°C, and incubate at 28°C Ferment for 20 hours to form seed liquid, wash the brewer's grains twice with water, add 20mL of fermentation culture liquid, and then add 8% seed liquid, ferment at 28 ℃ for 56h, add 20mL of distilled water to the fermentation bottle to wash the brewer's grains twice, and collect supernatant, inject more than twice the volume of acetone into the hair supernatant, and vacuum-dry at 50°C to obtain the crude bioflocculant sola gum.

[0040] Flocculation treatment of Yangtze River water in Nanjing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com