Sewage treatment system

A sewage treatment system and sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of unfavorable sludge settlement and solution splashing out of the reaction tank External and mud scraper movements are hindered, achieving the effect of reducing sludge treatment costs, reducing manual labor, and reducing the number of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

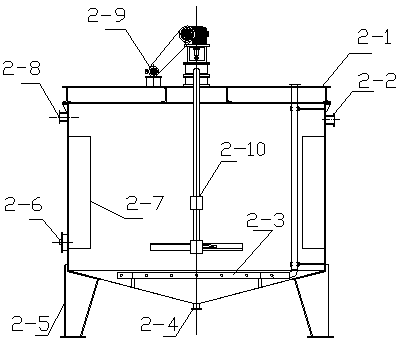

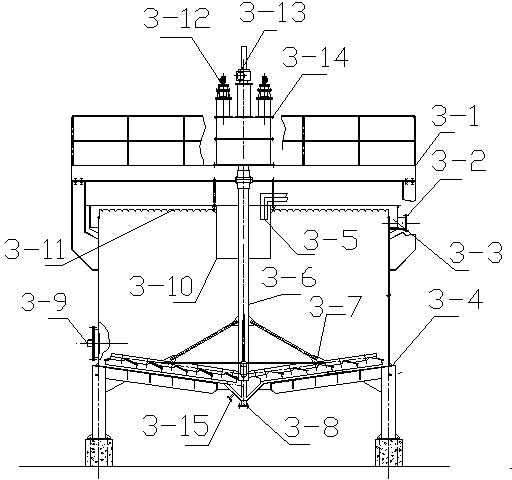

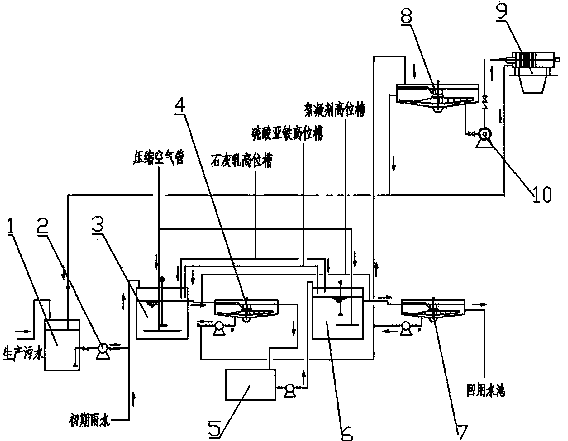

[0031] A sewage treatment system, which includes a sewage regulating tank 1, a primary neutralization reaction tank 3, a primary thickener 4, a secondary neutralization reaction tank 6, a secondary thickener 7, a sludge thickening tank 8, and a filter press 9. Pipelines, lifting pumps and motors, the sewage regulating tank 1 is connected to the inlet pipeline of the first-level neutralization reaction tank 3 through the lifting pump 2, and the outlet pipeline of the first-level neutralization reaction tank 3 is connected to the inlet of the first-level thickener 4 Pipeline connection, the sludge outlet of the primary thickener 4 is connected to the sludge thickening tank 8 through the lift pump, the outlet pipe of the primary thickener 4 is connected to the intermediate pool 5, and the intermediate pool 5 is connected to the secondary neutralization reaction tank through the lift pump 6, the outlet pipeline of the secondary neutralization reaction tank 6 is connected to the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com