Integrated tool-setting type numerical-control engraving machine portal frame assembly

A knife-shaped, integral technology, applied in engraving, processing models, decorative arts, etc., can solve problems such as unfavorable engraving accuracy, X-direction rail fatigue, short service life, etc., to improve walking accuracy and engraving accuracy, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

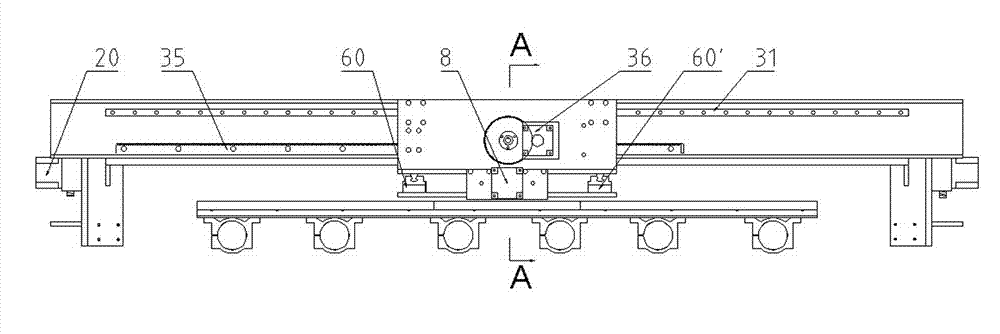

[0023] Such as Figure 1 to Figure 5 It can be seen that the present invention can be used as the gantry of the numerical control engraving machine.

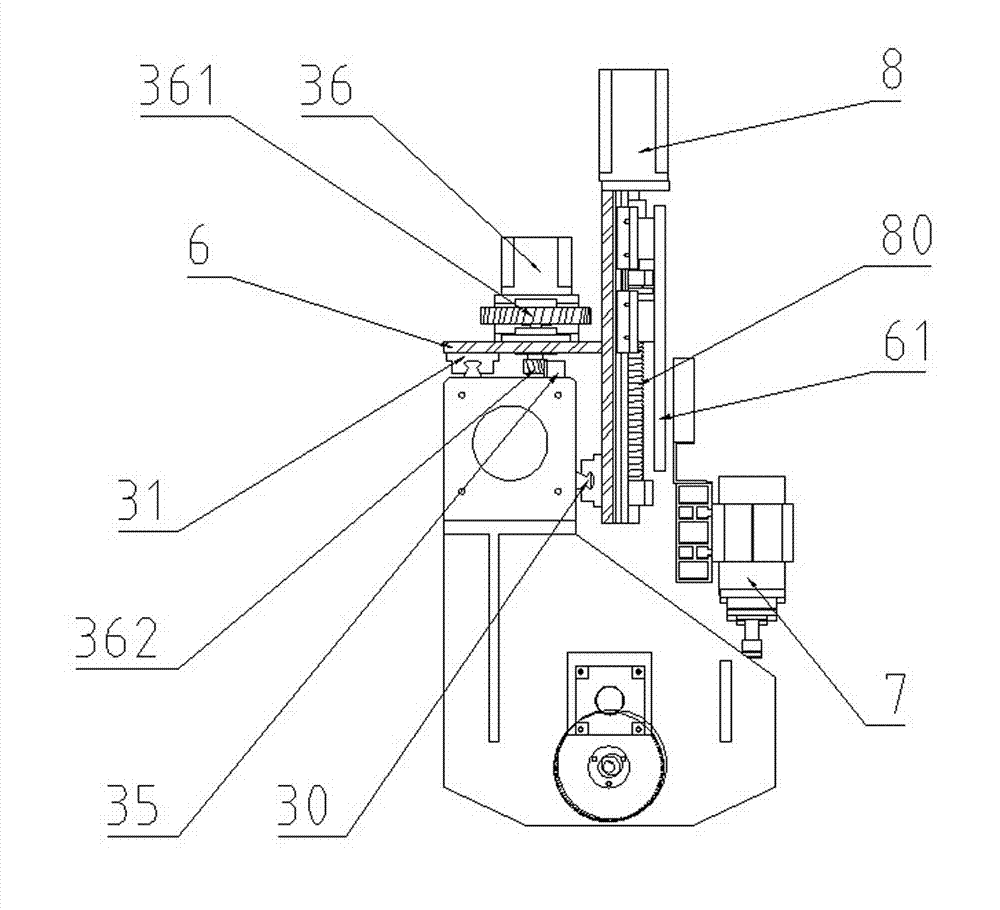

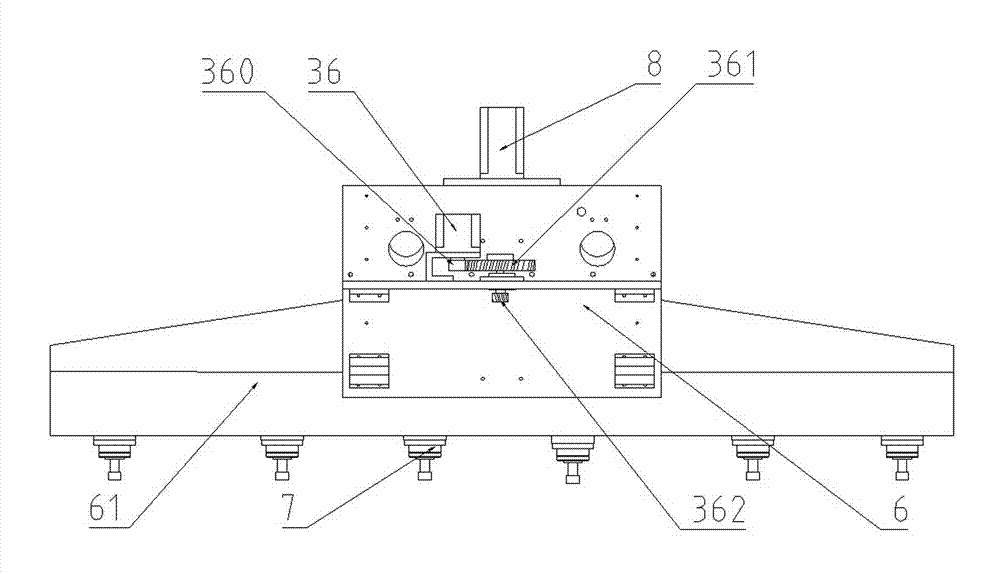

[0024] The numerical control engraving machine includes a bed body 1, on which a left column 2 and a right column 2'are movably connected by a left guide rail 10 and a right guide rail 10', the left column 2, the right column 2 A Y-direction driving device is also arranged between the'and the bed body 1, and a gantry 3 is arranged above the left column 2, the right column 2', and an X-direction vertical guide 30 is arranged on the vertical surface of the gantry 3, and an X-direction vertical guide rail 30 is arranged on the horizontal surface. X-direction horizontal guide rail 31, the gantry 3 is movably provided with a mobile base 6 through the X-direction vertical guide rail 30 and X-direction horizontal guide rail 31. The mobile base 6 is composed of mutually perpendicular horizontal plates and vertical plates. The base left gu...

Embodiment 2

[0040] The difference from the first embodiment is that this embodiment uses a screw drive in the X direction.

[0041] by Image 6 It can be seen that the X-direction drive device includes an X-direction drive motor 32 set on the gantry 3, and also includes an X-direction screw 33 connected to the main shaft of the X-direction drive motor 32. The moving base 6 and the X-direction screw 33 pass Screw drive connection. Specifically, the cross section of the mobile base 6 is in the shape of "┠", which includes a horizontal plate and a vertical plate that are fixed to each other. The X-direction screw 33 is connected to the mobile base 6 in the middle below the horizontal plate, and the transmission is stressed. Evenly. In the present invention, the movable base 6 is connected by the X-direction vertical guide rail 30 and the X-direction horizontal guide rail 31 provided on two different end faces of the gantry 3. Therefore, in the X direction, the method of adjusting the partial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com