Outer wire winding machine for cylindrical workpieces

A wire winding machine and workpiece technology, which is applied in the field of electric pole steel frame manufacturing, can solve the problems of limited inner diameter of the main drum, high manufacturing cost, and influence on production progress, and achieve uniform and reasonable winding spirals, reduce production costs, and save manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

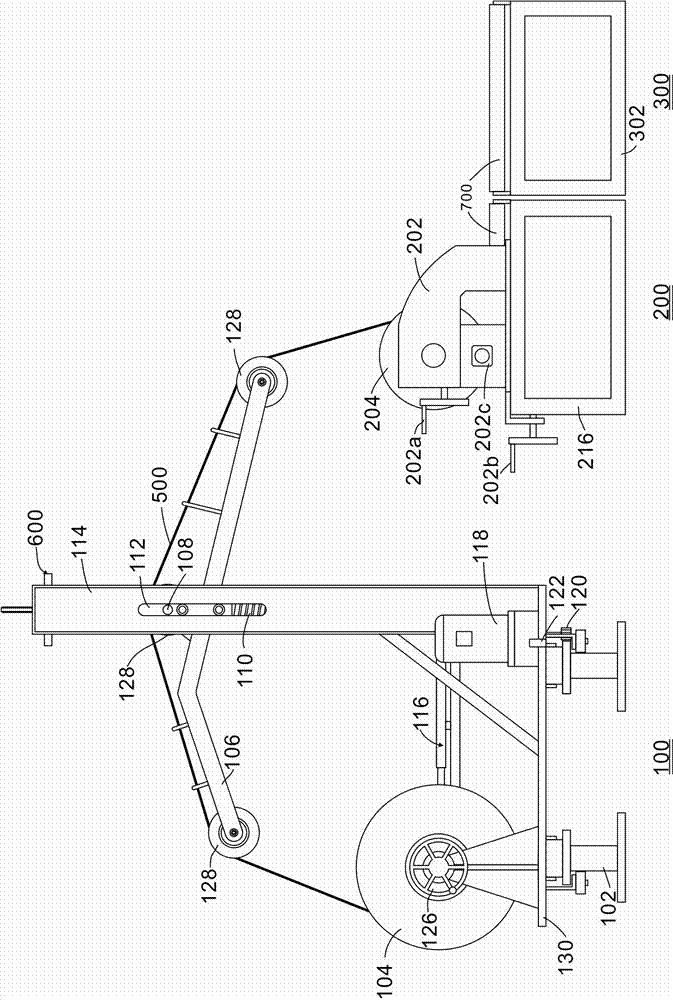

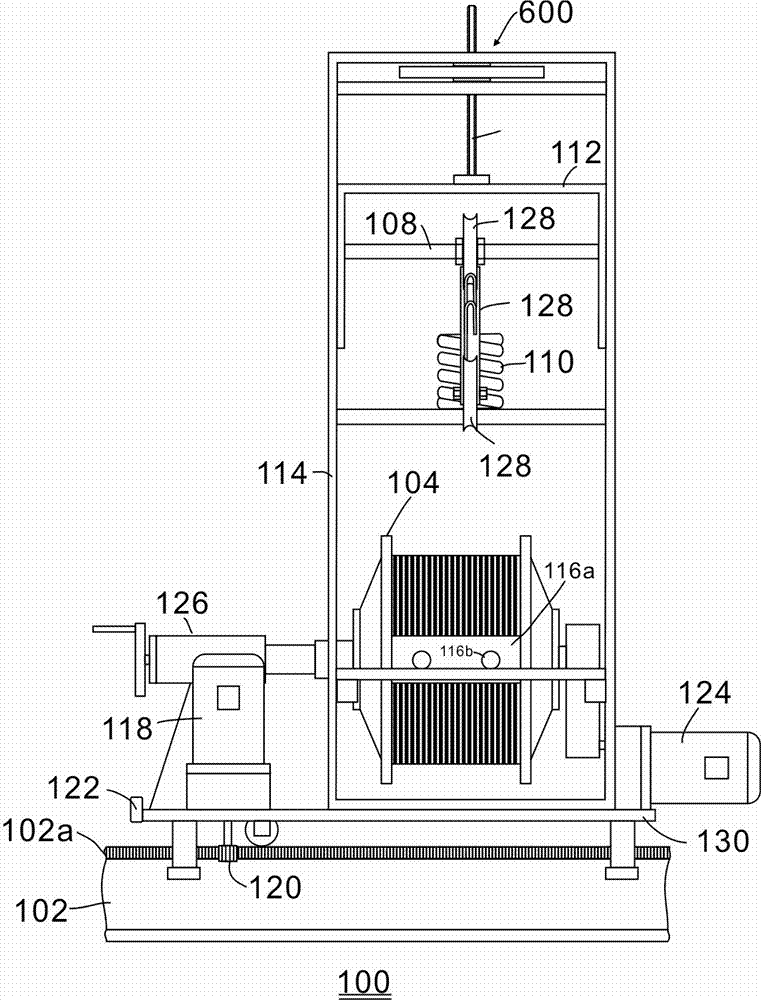

[0058] -Such as Figure 1 to Figure 3As shown, the outer wire winding machine for cylindrical workpieces includes a control system, a wire feeding mechanism 100 and a cylindrical workpiece rotating mechanism 200 arranged aside; The rotating mechanism 200 is responsible for driving the cylindrical workpiece to be wound by the wire to rotate; the two mechanisms cooperate to make the wire 500 tightly and evenly wound on the outer surface of the cylindrical workpiece, without further tightening treatment, which reduces production costs and saves production costs. Time, but also to ensure product quality. For example, when it is used for cold drawing and winding on the outer surface of the steel bar skeleton of the electric pole, since the cold drawing can be tightly wound on the outer surface of the steel bar skeleton of the electric pole, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com