High-performance micro-nano multi-level structure BiOCl photocatalytic material and preparation method thereof

A photocatalytic material and high-performance technology, applied in the field of nanomaterials and photocatalysis, can solve problems such as difficult recycling, achieve the effects of overcoming difficult recycling, inhibiting hydrolysis, and improving light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

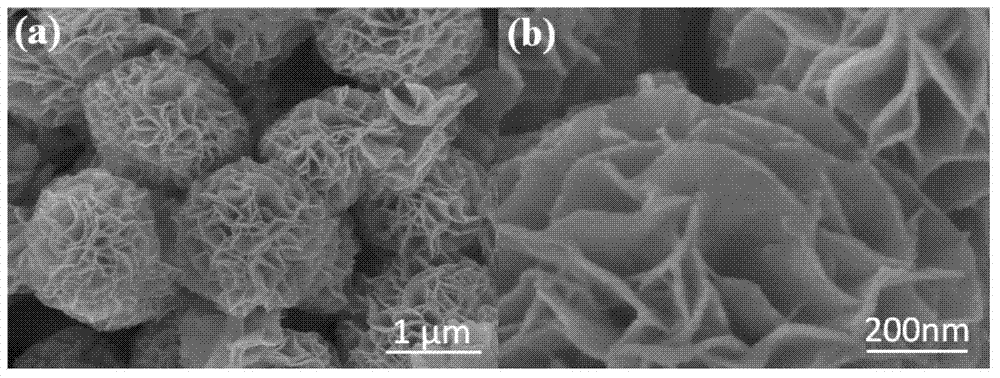

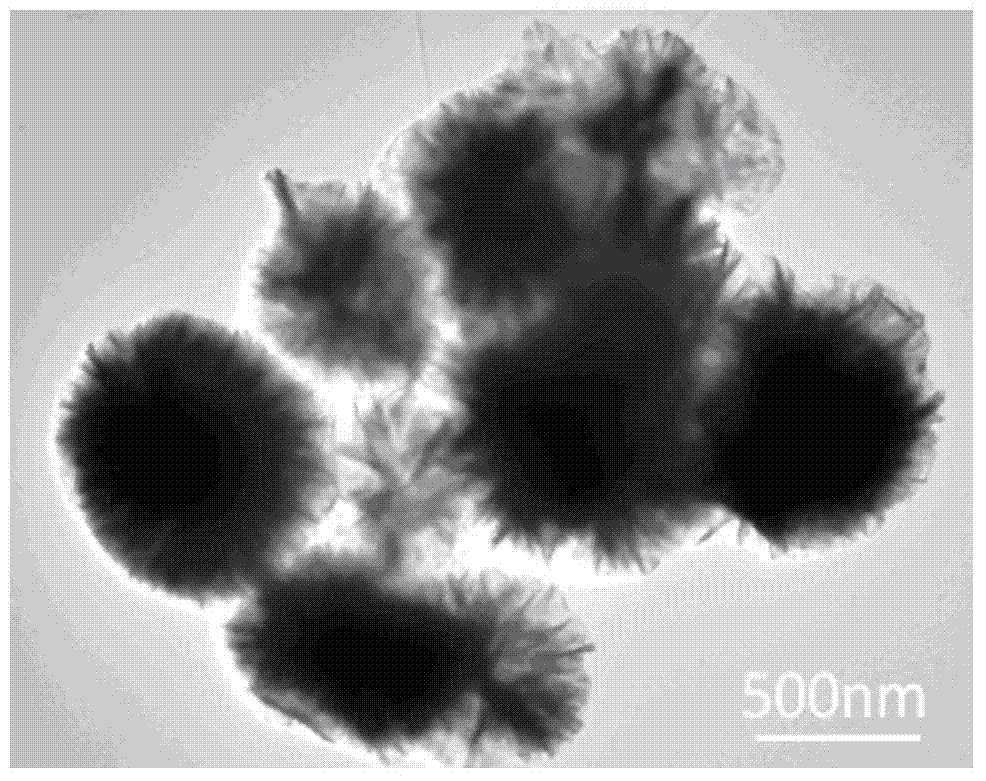

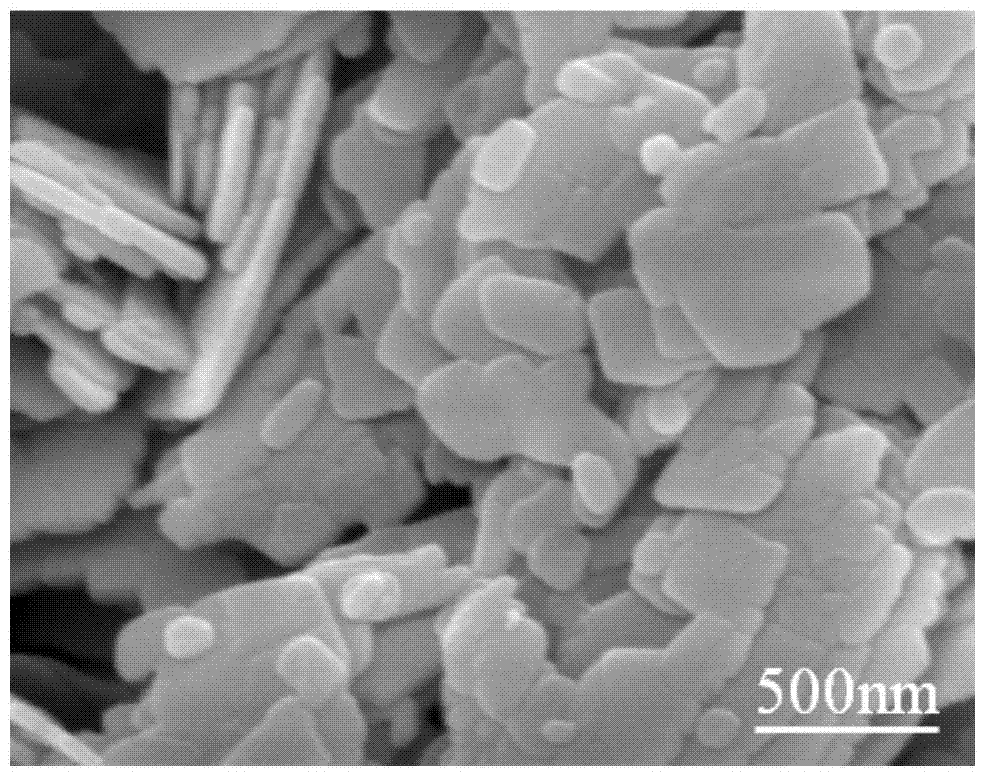

[0027] With Bi(NO 3 ) 3 .5H 2 O was used as the bismuth source, NaCl was used as the chlorine source, and biodegradable surfactant polyvinyl alcohol (PVA) was introduced to synthesize high-performance micro-nano hierarchical structure BiOCl photocatalytic materials in one step.

[0028] 2ml of concentrated HNO with a mass fraction of 65% 3 Dissolve in 20ml of water to prepare 1.3mol / L HNO 3 solution, HNO 3 Only when the solution concentration is ≥1.3mol / L can the subsequent Bi(NO 3 ) 3 .5H 2 Hydrolysis does not occur when O dissolves.

[0029] Quickly weigh 8mmol of Bi(NO 3 ) 3 .5H 2 O, and dissolve it in the above-mentioned 1.3mol / L HNO 3 In the solution, it is fully dissolved under the condition of magnetic stirring, and the Bi(NO 3 ) 3 -HNO 3 mixture.

[0030] Under the conditions of ultrasonic dispersion and mechanical stirring, 20ml of NaCl aqueous solution (8mmol) and 5ml of pre-prepared 5% polyvinyl alcohol aqueous solution were dropped into the above-pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com