Improved wide-width horizontal type mini-tiller

A wide horizontal, micro-tiller technology, applied in the field of rotary tillers, can solve the problems of easy entanglement of grass, affecting the health of operators, and easy skew of the rotary tiller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

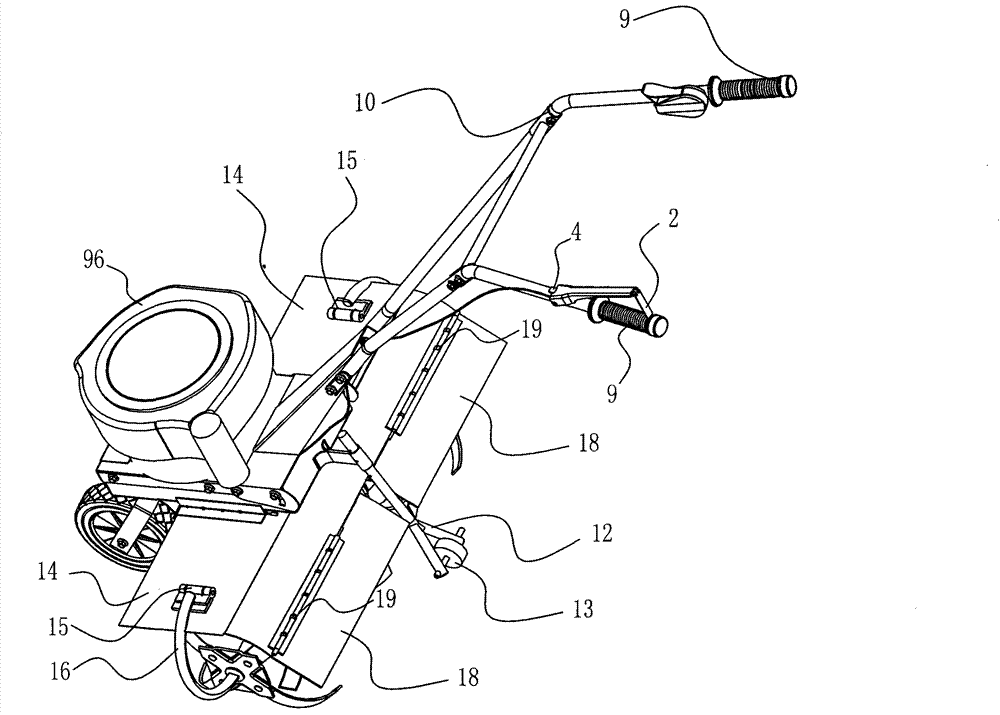

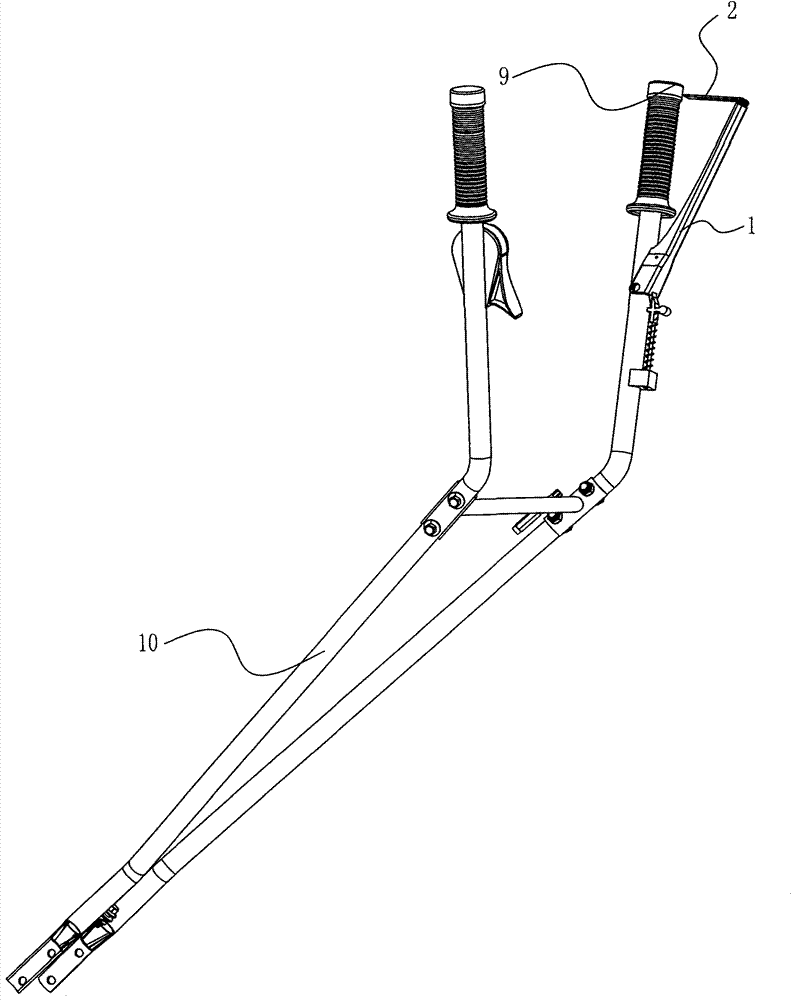

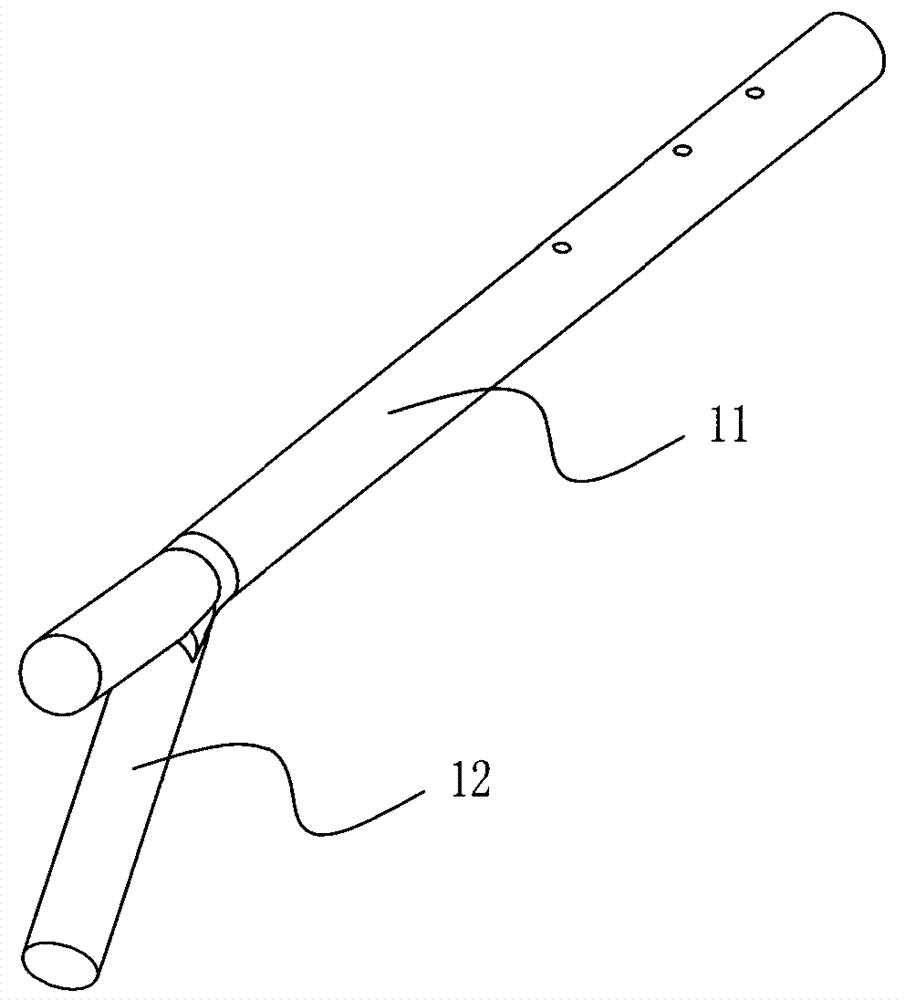

[0183] The invention relates to an agricultural and animal husbandry machine, which belongs to the technical field of rotary tillers, in particular to an improved wide-width horizontal tiller, which is an improvement of a rotary tiller with various safety measures. The outer guard plate is designed to reduce vibration and enhance vitality with a wide range, and the effect of multi-point uniformity is safer. That is, the improved rotary cultivator with safety follower guard frame, double-action safety switch and safety resistance fork wheel can be used for multi-purpose engines, such as gasoline engines, to improve the gasoline engines originally used for lawn mowers, It can also be used for rotary tillers driven by electric motors, and the invention is also suitable for refitting various small rotary tillers and miniature rotary tillers. Food is the most important thing for the people, so cultivated land is the most important; according to customer requirements, there are fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com