Positioning mechanism and laminating equipment using same

A technology of positioning mechanism and lamination equipment, applied in metal processing equipment, large fixed members, metal processing machinery parts, etc., can solve the problems of inconsistent height, skew of the second workpiece, affecting the lamination yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

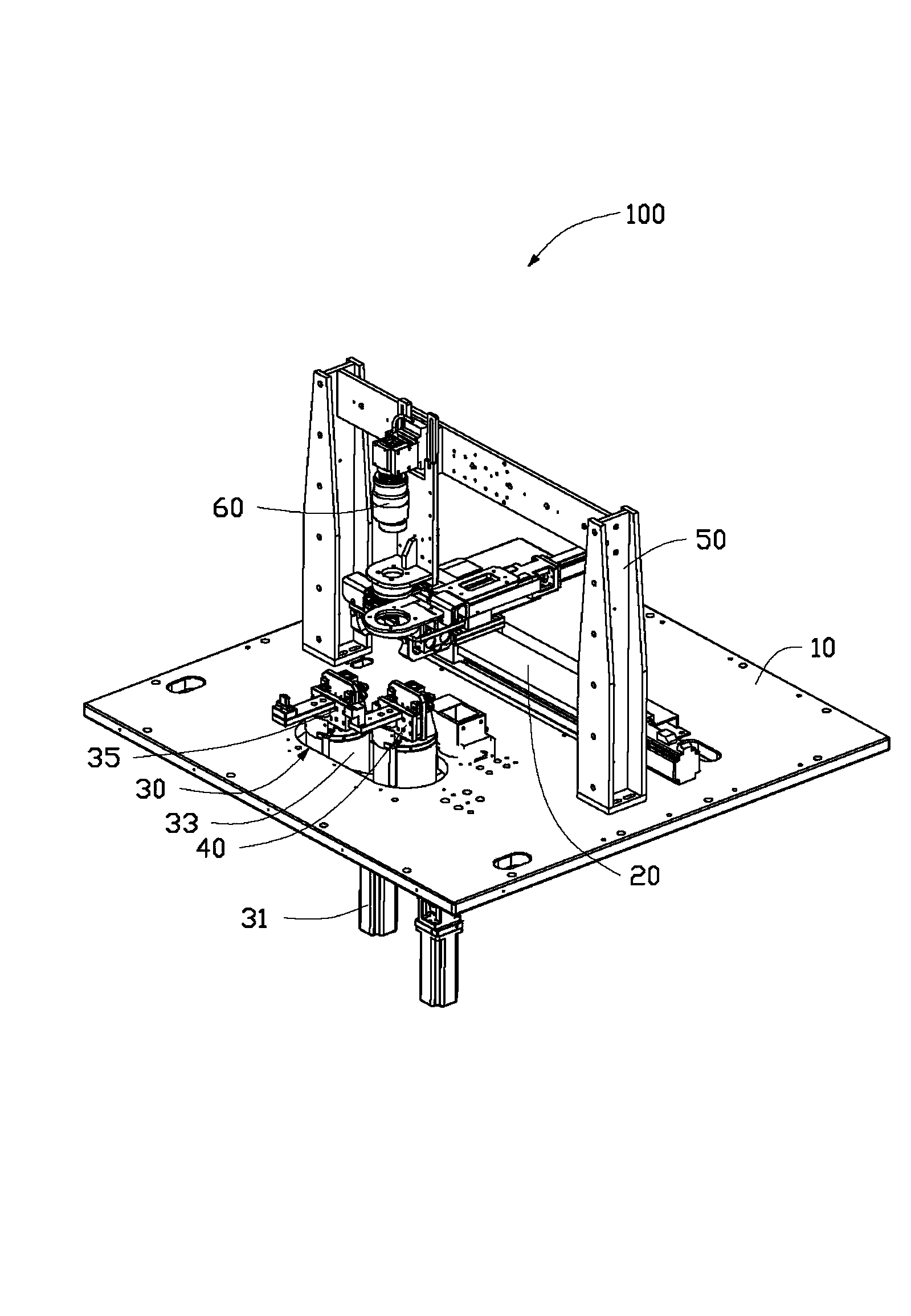

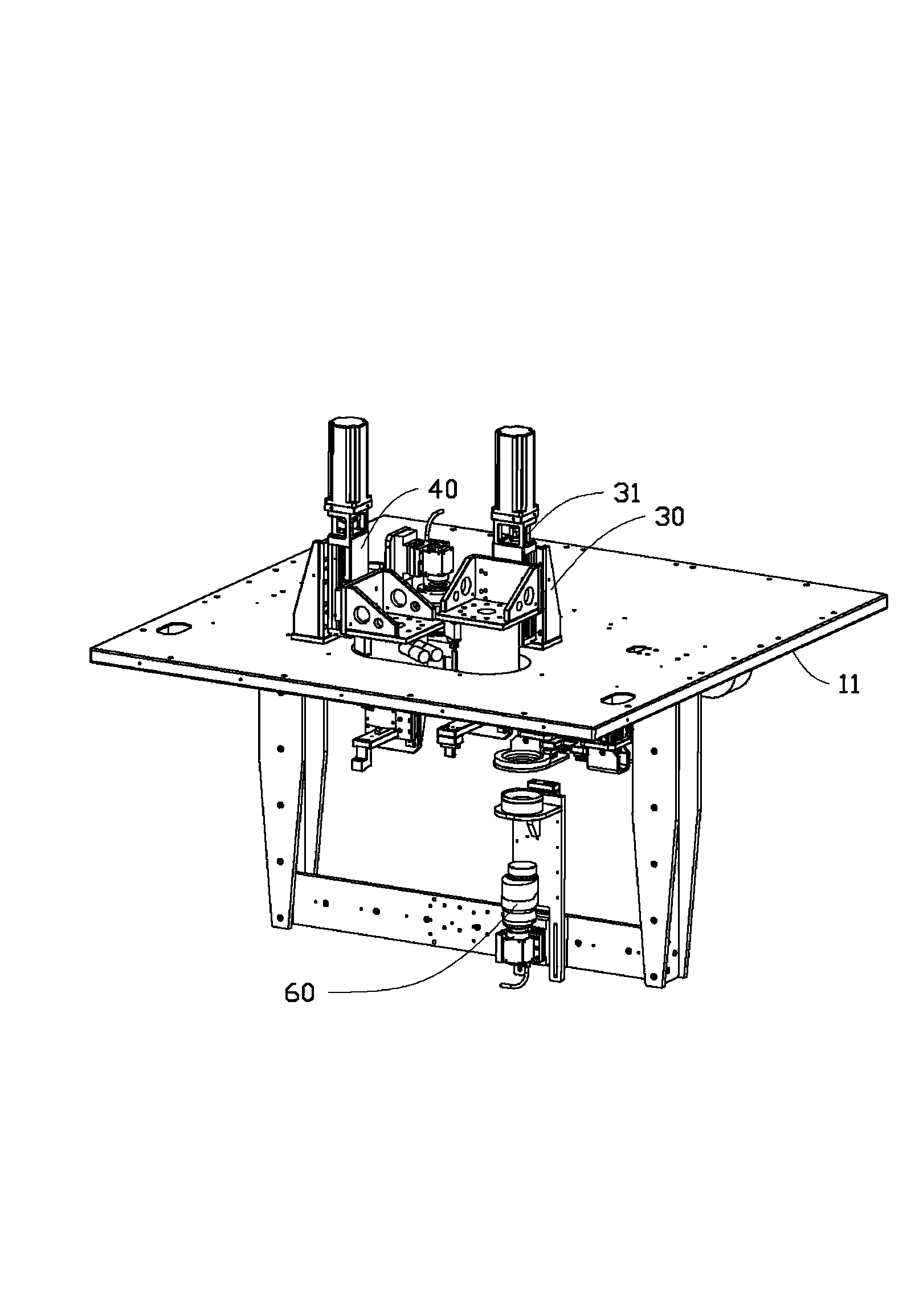

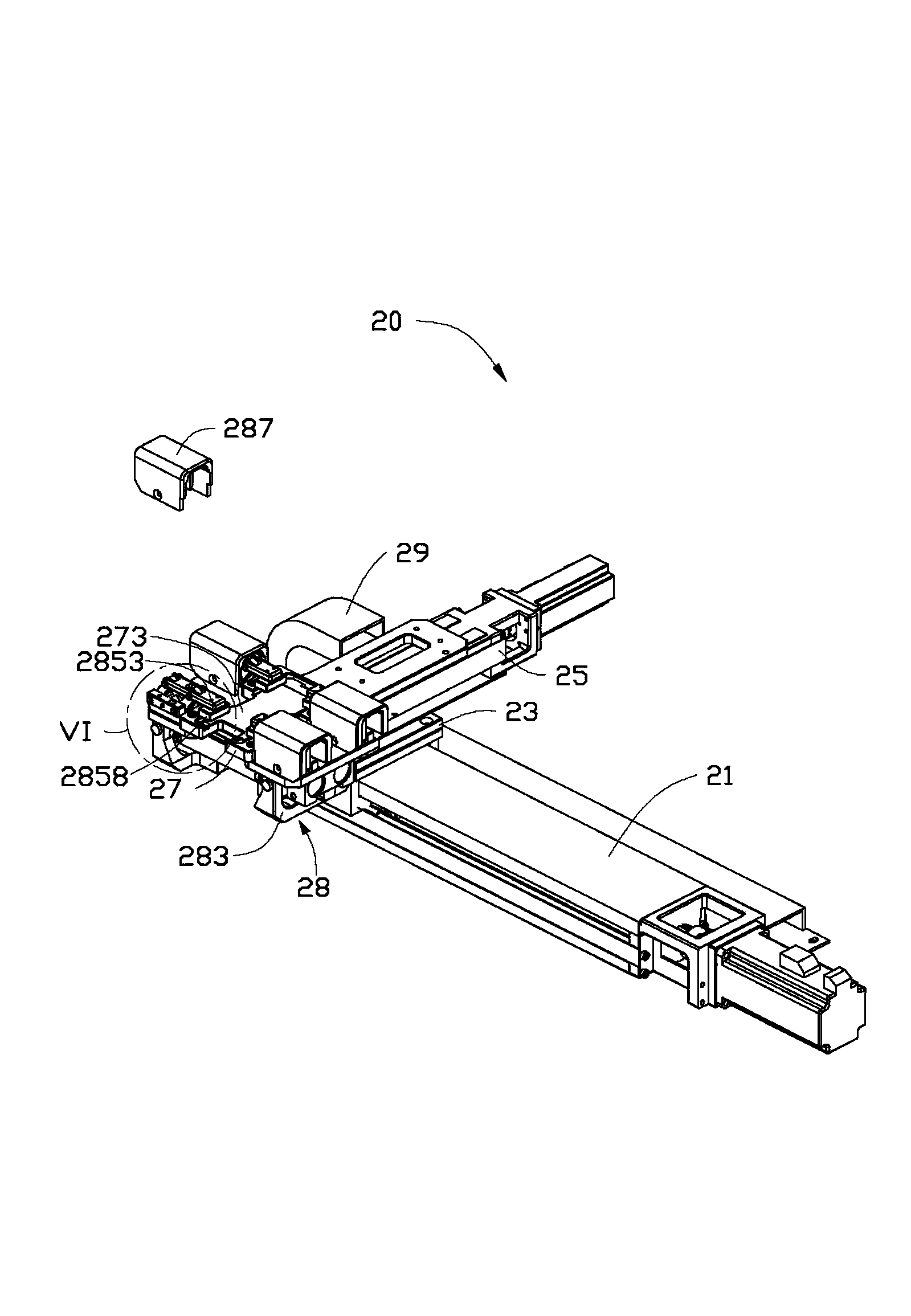

[0017] see figure 1 and figure 2 , the laminating equipment 100 of this embodiment includes a machine platform 10, a positioning mechanism 20 installed on the machine platform 10, a first laminating mechanism 30, a second laminating mechanism 40, a bracket 50, and a positioning mechanism installed on the bracket 50. The first detection module 60 and the second detection module (not shown) installed on the machine 10 . The positioning mechanism 20 is used to move and position the first workpiece (not shown). The first attaching mechanism 30 is used to attach the second workpiece (not shown) to the first workpiece, and the first detection module 60 is used to detect the positioning deviation of the second workpiece relative to the first workpiece. The second attaching mechanism 40 is used for attaching the third workpiece (not shown) to the second workpiece. The second detection module is used to detect the positioning deviation of the third workpiece relative to the first w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com