A safety grade electrical connector

An electrical connector, safety-level technology, applied in the field of safety-level electrical connectors, can solve the problems of connection failure, long monitoring time, etc., and achieve the effect of maintaining integrity, high tensile strength, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

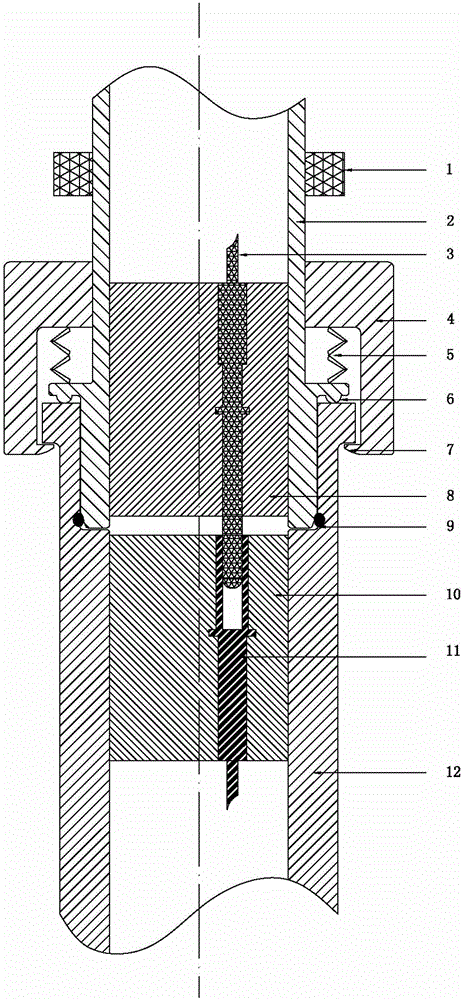

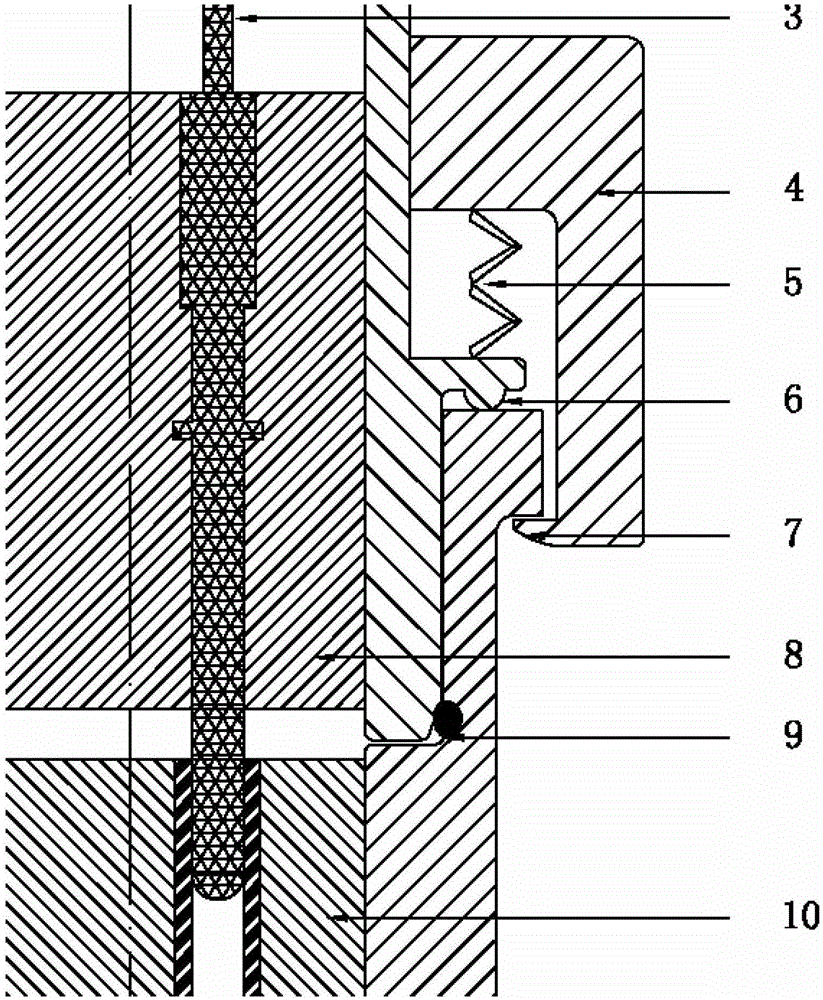

[0029] Such as figure 1 , figure 2 As shown, the safety level electrical connector of the present invention includes a limit nut 1, a plug body 2, a male needle core 3, a fastening clip 4, a compression spring 5, a main sealing ring 6, a clip barb 7, PEEK Insulator A8, sealing gasket 9, PEEK insulator B10, female contact core 11, socket body 12;

[0030] The plug body 2 is cylindrical, wherein the outer side of the lower part has an annular boss, and the lower side of the boss has an annular ring with a semicircular cross section, which is the main sealing ring 6, and the outer side of the lower end of the cylinder has an annular conical surface. The angle meets: 15°≤angle≤30°; the upper part of the plug body 2 is provided with a limit nut 1 to prevent the fastening clip 4 from falling off; the fastening clip 4 is a cylinder, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com