Early diagnosis method for faults of strip steel tension sensor

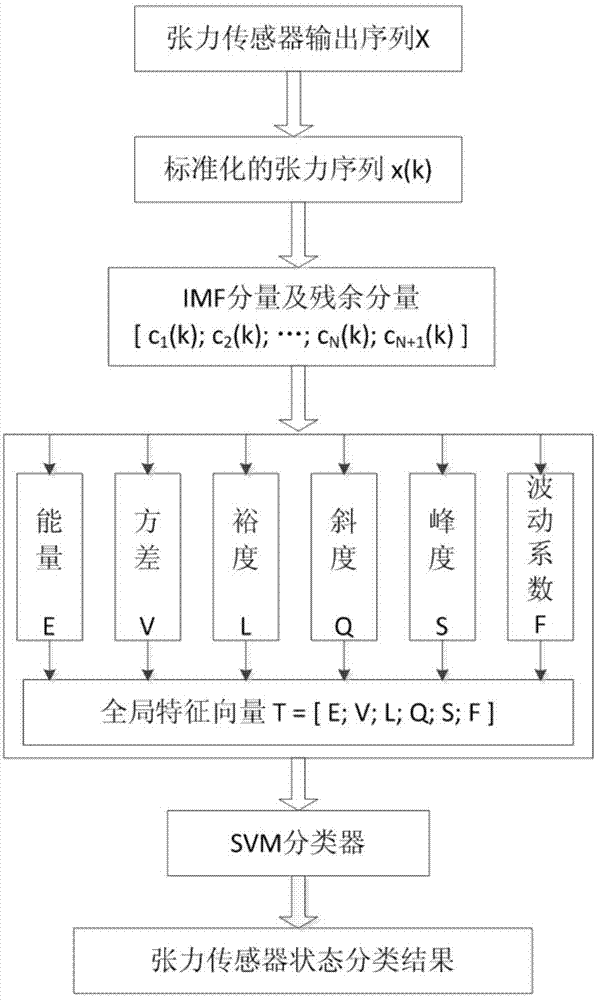

A technology of tension sensor and early diagnosis, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., and can solve the problems that time domain analysis cannot effectively detect fault characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

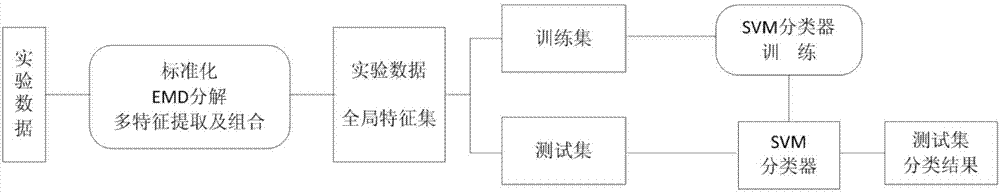

Method used

Image

Examples

specific Embodiment

[0039] The experimental data used in this embodiment is obtained by on-site collection and simulation program simulation, and the specific process is as follows:

[0040]1. The normal data is collected from the on-site tension measurement system under normal working conditions. A total of 100 strip tension sequences are collected from certain characteristic data of the tension sensor, and the data length of each strip tension sequence is 300.

[0041] 2. Randomly select a position in the length interval from 1 / 3 to 1 / 2 of each normal data sequence (ie [100,150]), so that the sequence value after the random position is a constant value (the constant value of each piece of data is a random value within a certain range), to simulate the failure data of the tension sensor.

[0042] (3) Randomly select a position on the length interval from 1 / 3 to 1 / 2 of each normal data sequence (ie [100,150]), and add or subtract a constant value to the sequence value after the random position (e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com