Device and method for testing non-linear rigidity and damping of hard coating composite structure

A composite structure and hard coating technology, which is used in measuring devices, using repetitive force/pulsation force to test the strength of materials, and measuring mechanical impedance, etc., can solve the problem of effectively identifying the nonlinear stiffness and damping of hard coating composite structures. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

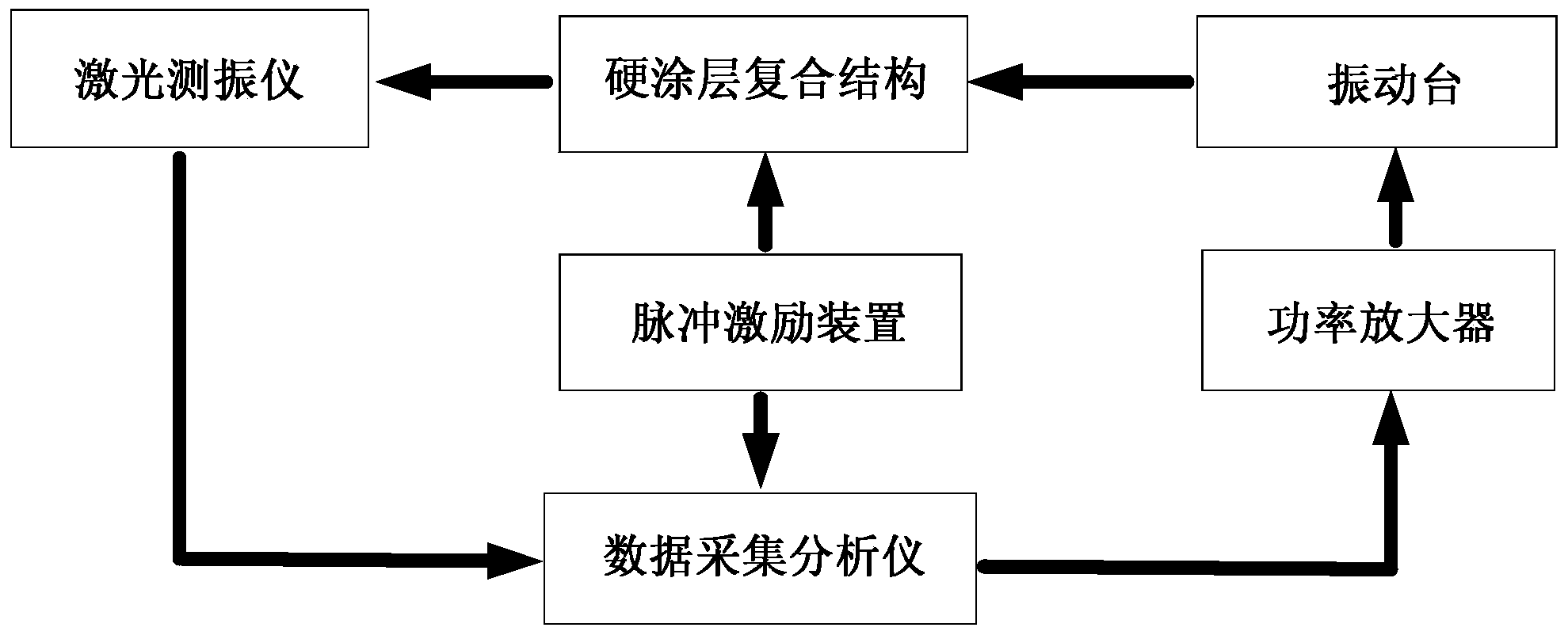

[0063] Such as figure 1 As shown, the device for testing the nonlinear stiffness and damping of a hard-coated composite structure in this embodiment includes: a pulse excitation device, a vibration table, a power amplifier, a data acquisition analyzer, a laser vibrometer, and a host computer;

[0064] The hard-coated composite structure is fixedly installed on the table of the vibrating table;

[0065] The output end of the pulse excitation device is connected to one input end of the data acquisition analyzer, the other input end of the data acquisition analyzer is connected to the output end of the laser vibrometer, one output end of the data acquisition analyzer is connected to the input end of the power amplifier, and the power The output end of the amplifier is connected to the vibration table, and the other output end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com