On-site testing platform for micromechanical property of material in shearing-torsion loading combination mode

A micromechanics, composite loading technology, applied in the direction of analyzing materials, measuring devices, scientific instruments, etc., can solve the problem that it is difficult to accurately express the loading form, stress, deformation, failure and failure of materials and components. Accurate performance evaluation and other issues, to achieve the effect of rich test content, small structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

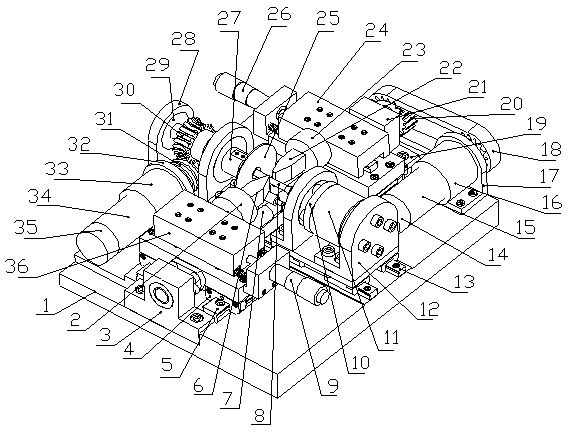

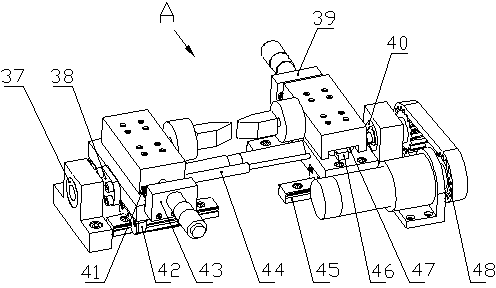

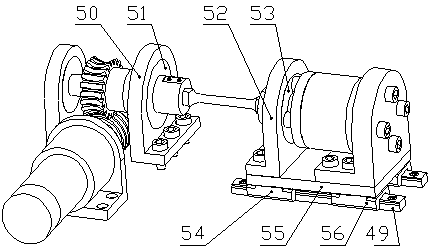

[0025] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0026] see Figure 1 to Figure 5 , an in-situ test platform for the micro-mechanical properties of materials in the shear-torsion composite loading mode, including a precision shear loading drive unit, a precision torsion loading drive unit, a mechanical and deformation signal detection unit, a specimen clamping unit, and a precision shear loading drive unit. The loading drive unit and the precision torsion loading drive unit are fixed on the test platform base 1 by bolts, so as to ensure that the linear movement direction output by the terminal of the precision shear loading drive unit is perpendicular to the axis of the rotational motion output by the terminal of the precision torsion loading drive unit; The specimen clamping unit cooperates with the precision torsional loading drive unit to realize the fixation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com