Shaft testing device capable of exerting two-stage combined tension-torsion loading simultaneously

A test device and composite load technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inconsistency of force conditions and inability to simulate turbine shaft loads, and achieve simple manufacturing and assembly. Experiment with full-featured, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

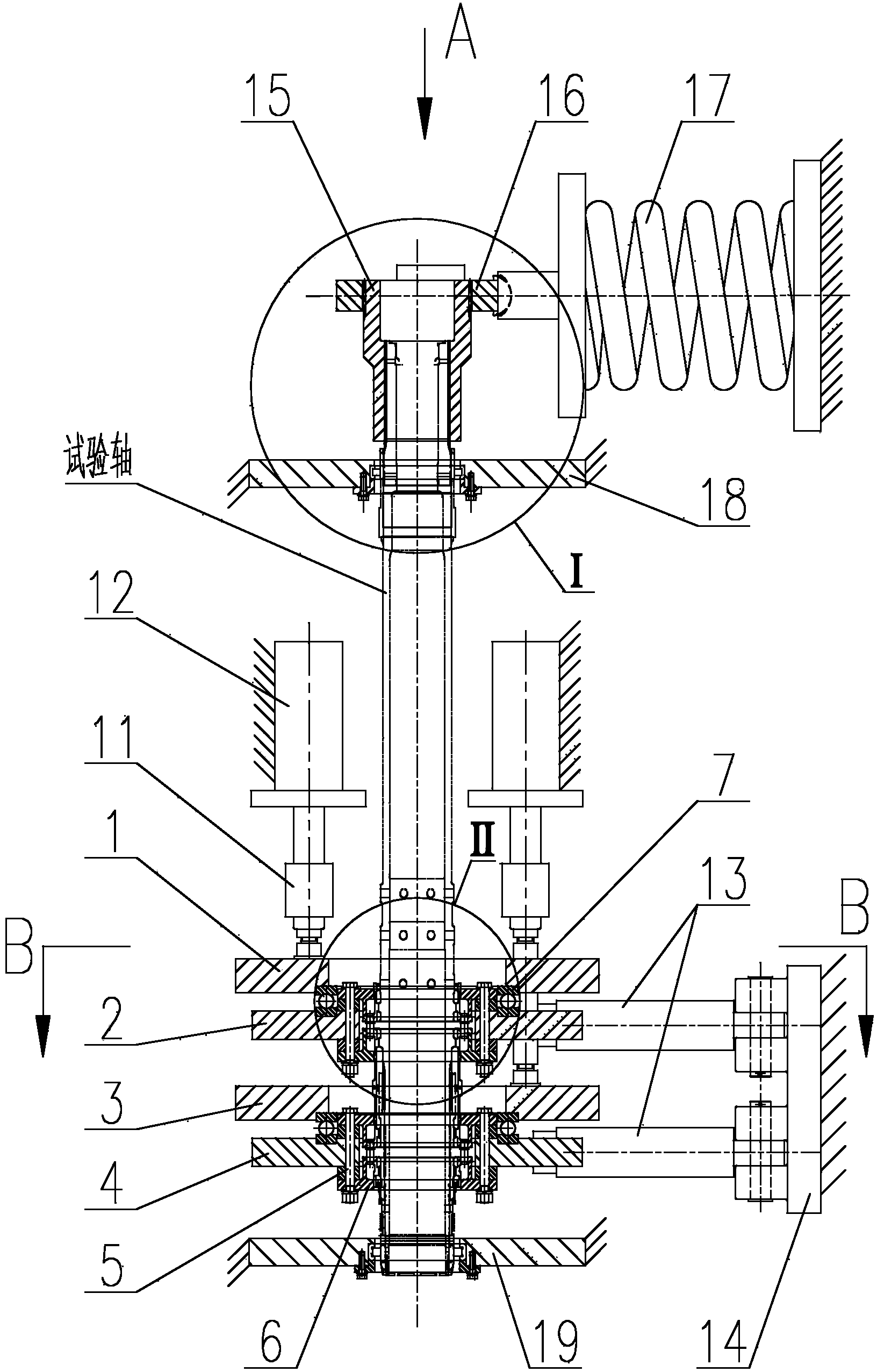

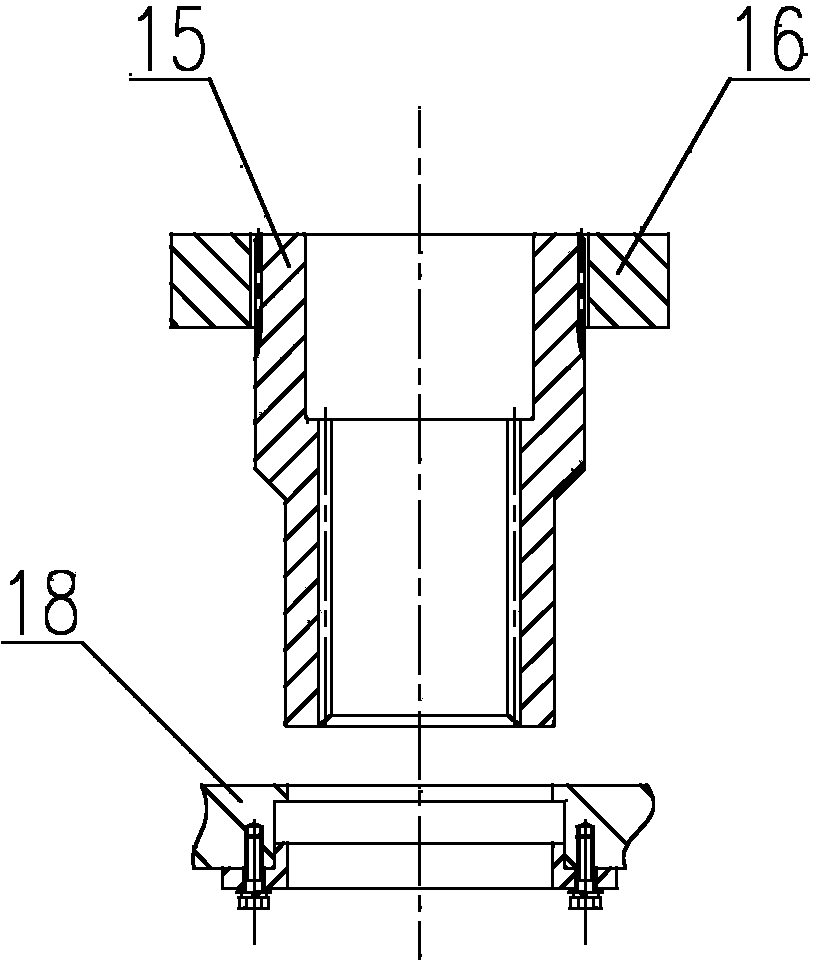

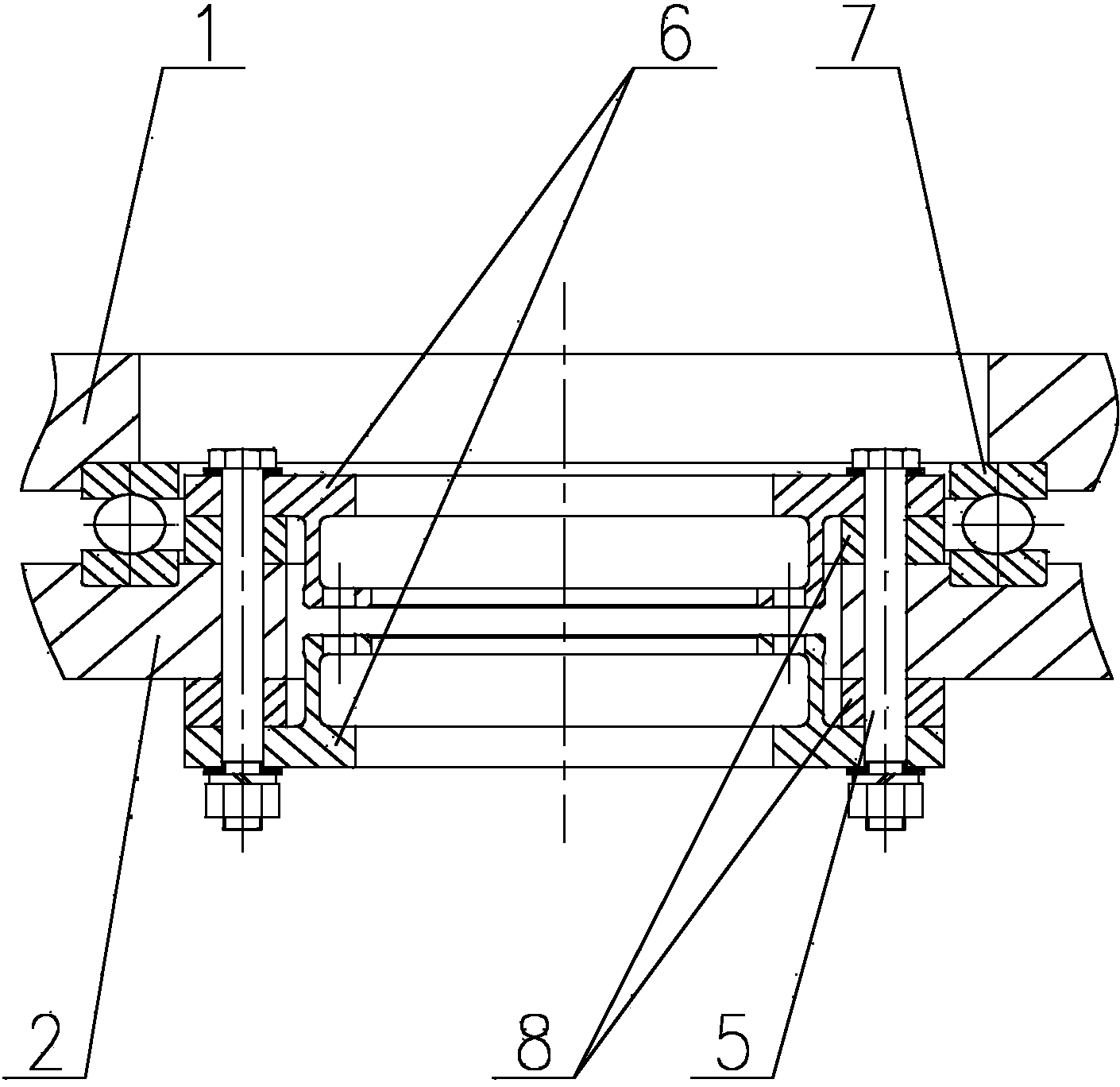

[0025] The shaft test device of this embodiment capable of applying two-stage tensile-torsion composite load at the same time has a structure as attached figure 1 to attach Image 6 As shown, the tested rotating shaft is the turbine shaft of a certain type of aero-engine. The specific structure of the test device is as follows.

[0026] 1. The overall structure of the test device is as attached figure 1 As shown, it consists of a device frame, a primary tension-torsion load loading module, a secondary tension-torsion load loading module, a counter-torque load loading module and a test shaft positioning device installed on the frame. The test device is a vertical structure as a whole, the torque loading oil cylinder 13 in the first-stage tension-torsion load loading module and the second-stage tension-torsion load loading module, and the return spring assembly 17 in the counter-torque load loading module are all set horizontally, and the first-stage tension and torsion load l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com