Nondestructive detection method for thickness of nacrelayer of pearl

A non-destructive testing, layer thickness technology, applied in measuring devices, instruments, using wave/particle radiation, etc., can solve the problems of measurement error, result error, difficult to measure the measured pearl, etc., to achieve accurate measurement results, error can be avoided. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

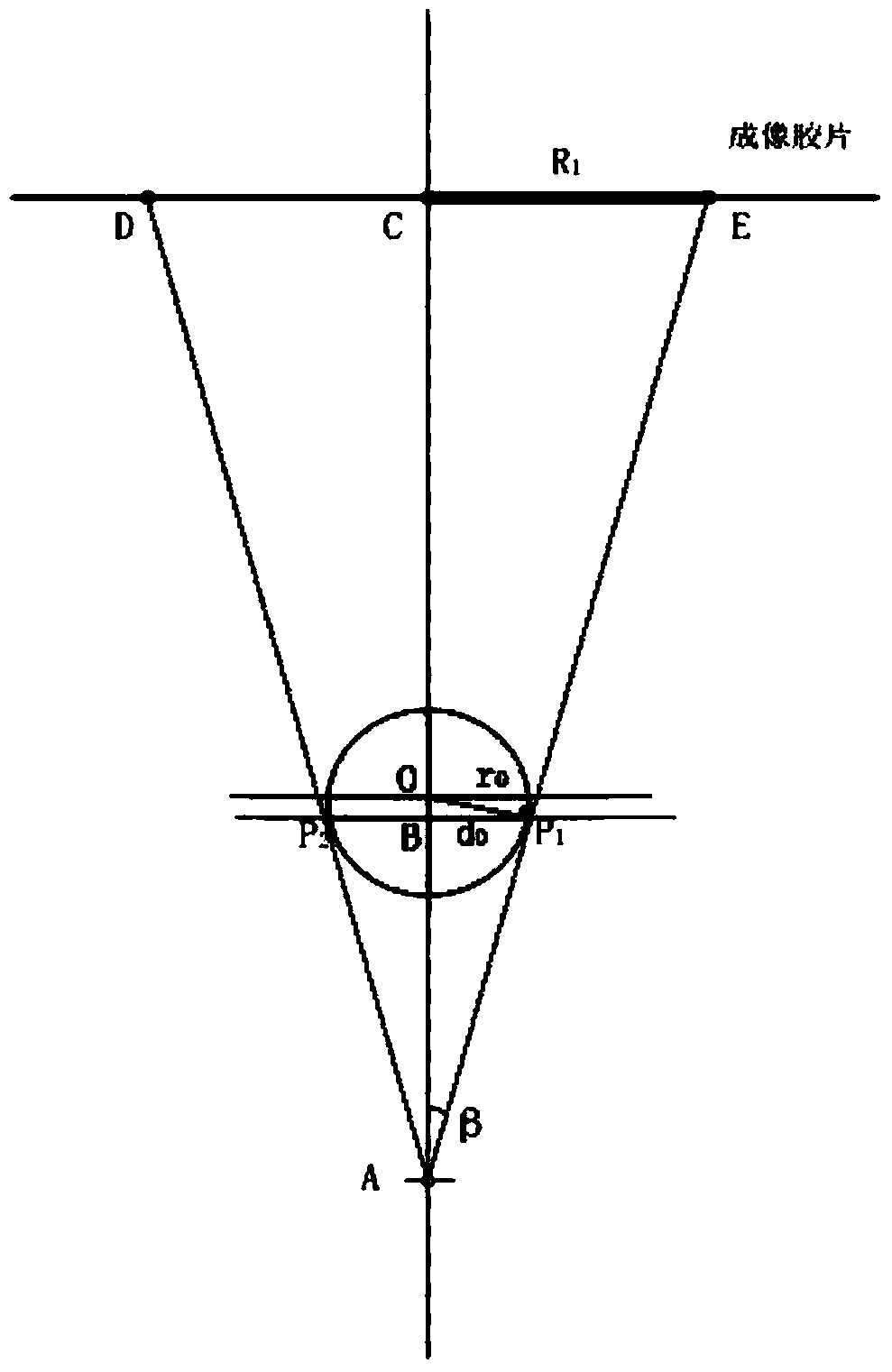

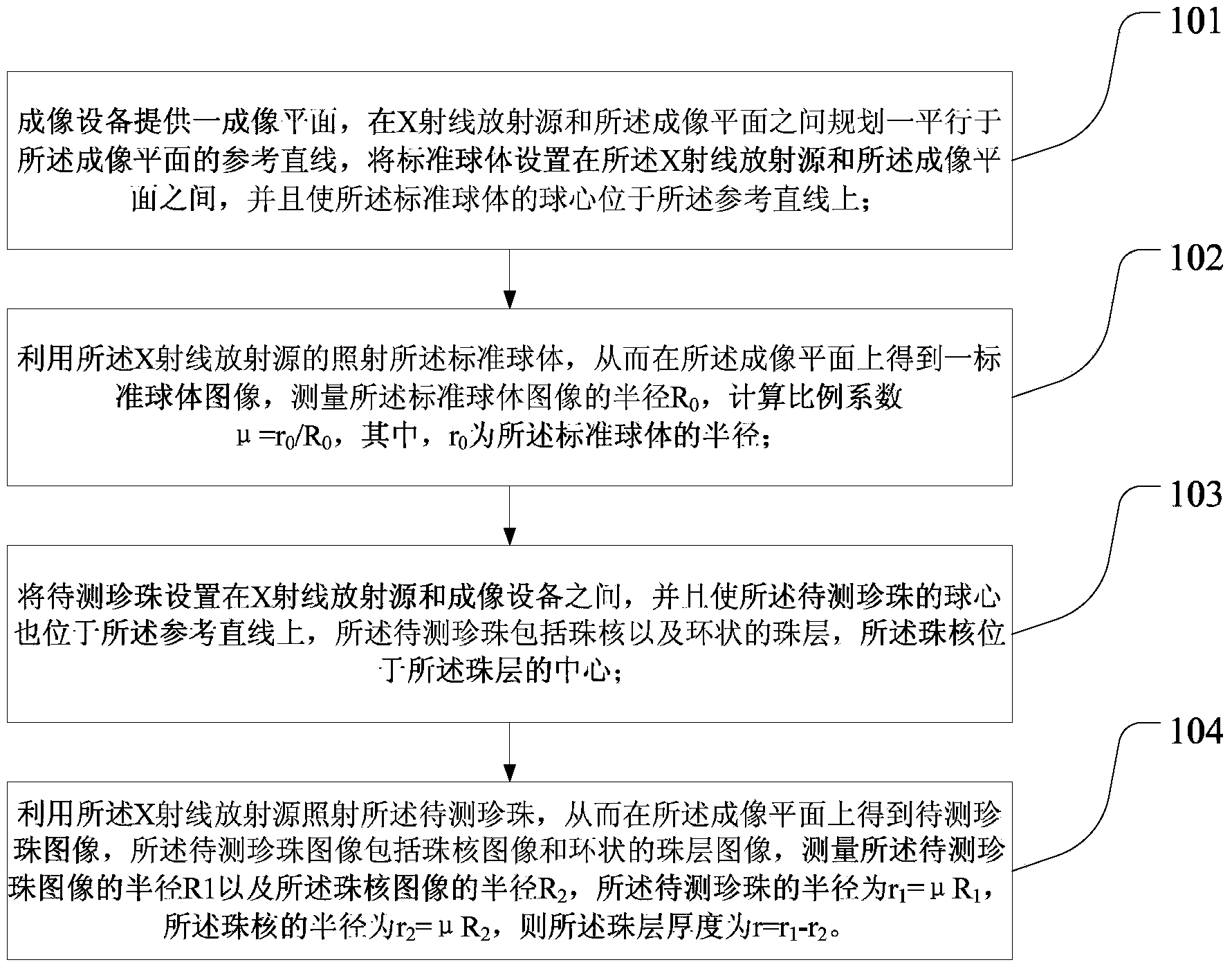

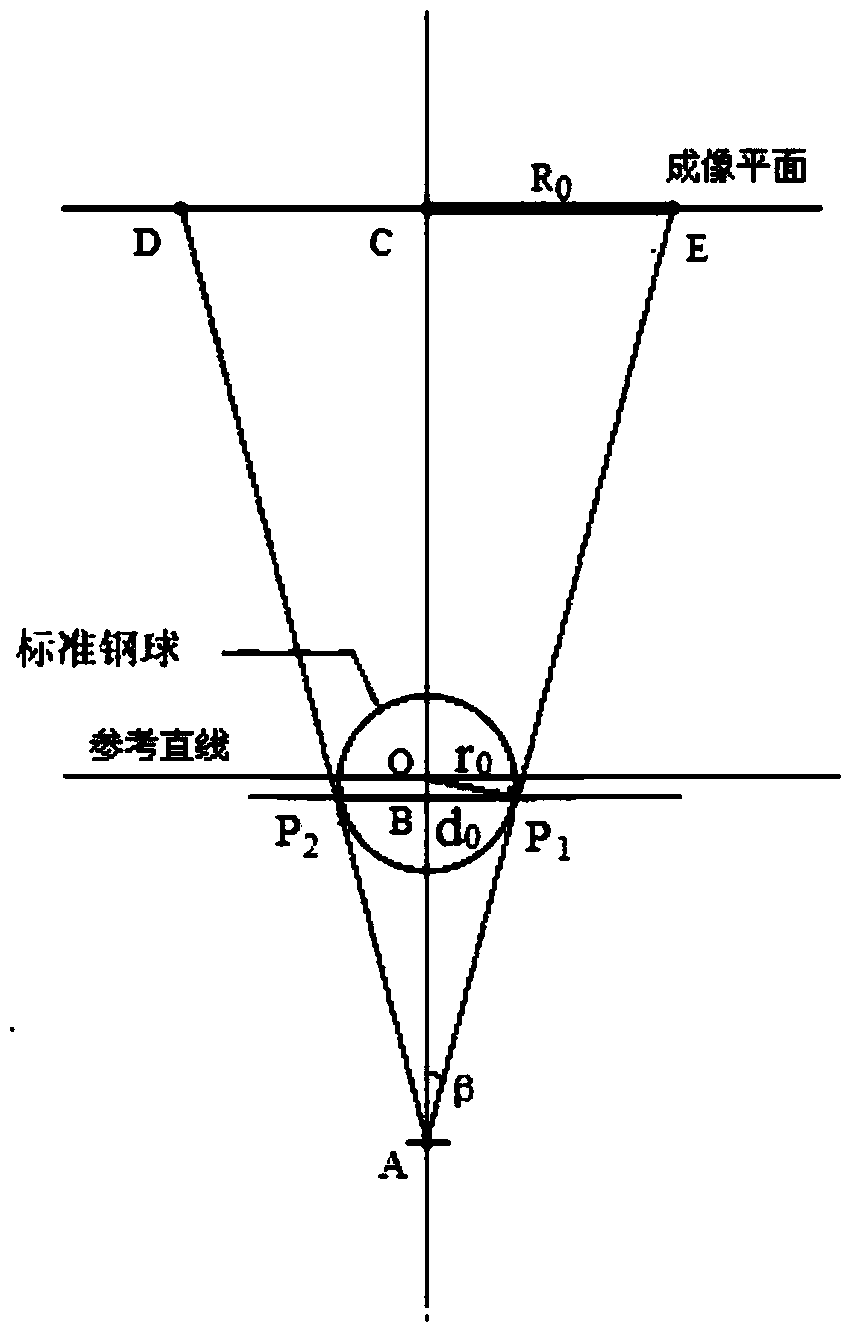

[0026] like figure 2 , shown in Fig. 3 (a) and Fig. 3 (b), the present invention provides a kind of non-destructive testing method of pearl bead thickness, comprises the following steps:

[0027] Step 101, the imaging device provides an imaging plane, plans a reference line parallel to the imaging plane between the X-ray radiation source and the imaging plane, and sets a standard sphere between the X-ray radiation source and the imaging plane between, and make the center of the standard sphere be located on the reference straight line;

[0028] Step 102, using the X-ray radiation source to irradiate the standard sphere, so as to obtain a standard sphere image on the imaging plane, and measure the radius R of the standard sphere image 0 , calculate the proportional coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com