Nondestructive detection method for thickness of nacrelayer of pearl

A non-destructive testing and layer thickness technology, applied in the direction of measuring devices, instruments, using wave/particle radiation, etc., can solve the problems of measurement errors, result errors, and difficulty in measuring the measured pearls, etc., to achieve accurate measurement results and accurate errors control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

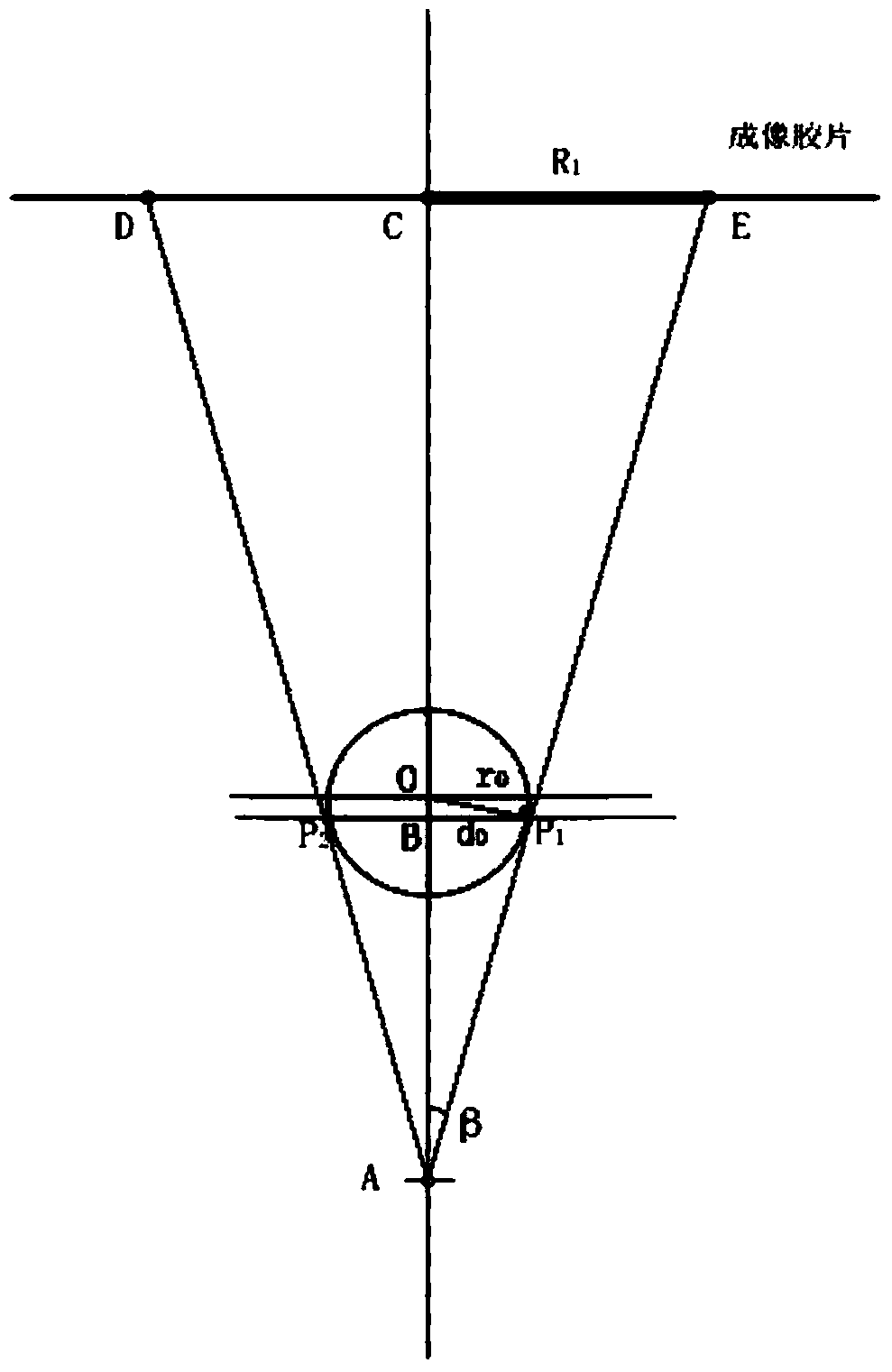

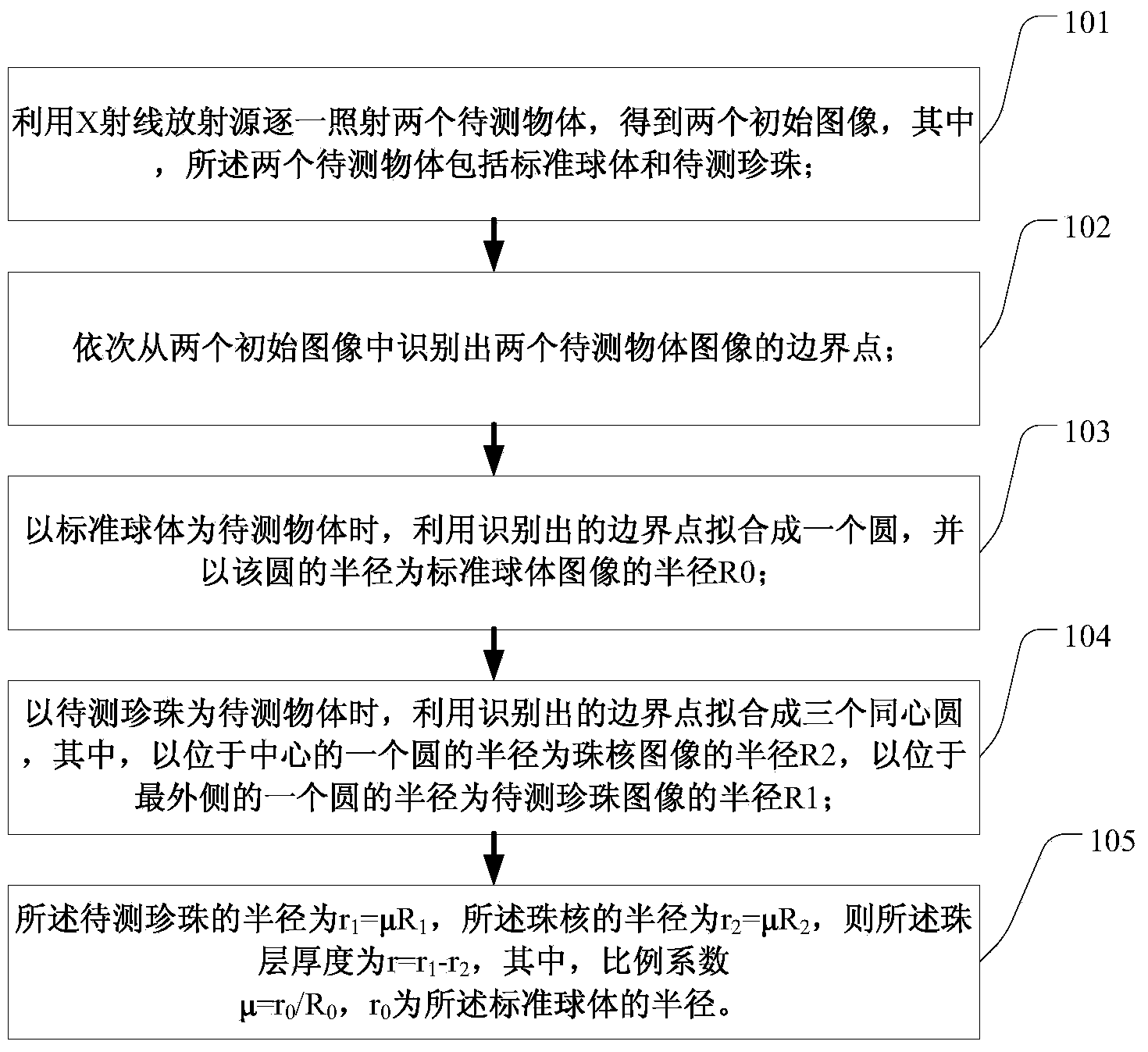

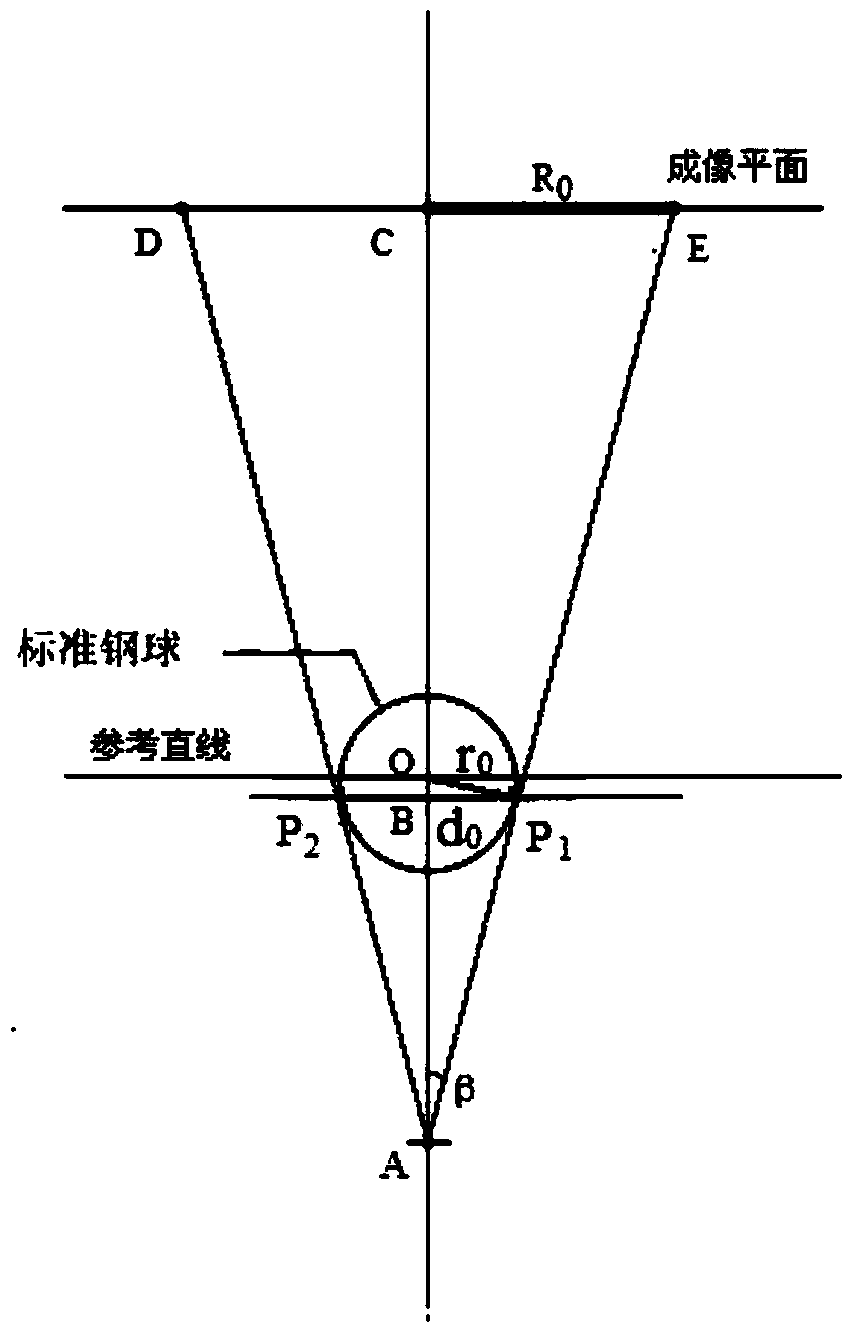

[0030] like figure 2 , Figure 3 (a) and Figure 3 (b), the present invention provides a non-destructive testing method for the thickness of a pearl bead layer, comprising the following steps:

[0031] Step 101: Use an X-ray radiation source to irradiate two objects to be tested one by one to obtain two initial images, wherein the two objects to be tested include a standard sphere and a pearl to be tested, wherein the pearl to be tested includes a bead nucleus and a ring to be tested. The bead layer, the bead core is located in the center of the bead layer;

[0032] Step 102: Identify the boundary points of the two images of the object to be measured from the two initial images in turn. The specific process is as follows: (1) The initial image is composed of a plurality of regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com