Coal slime drying system and coal slime drying process

A drying system and coal slime technology, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of high energy consumption and cost of microwave drying, and achieve the goals of improving use efficiency, protecting the living environment, and operating safely Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

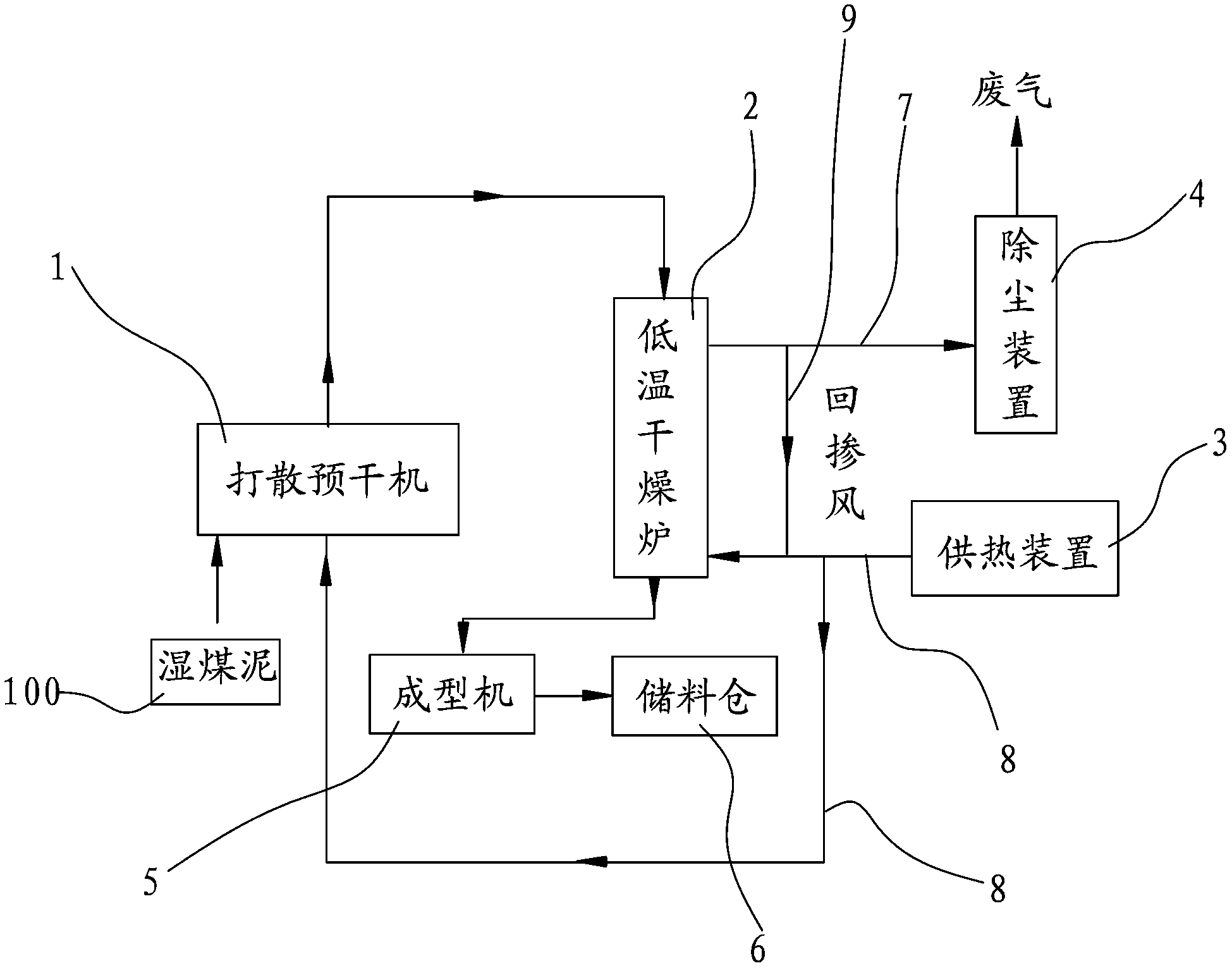

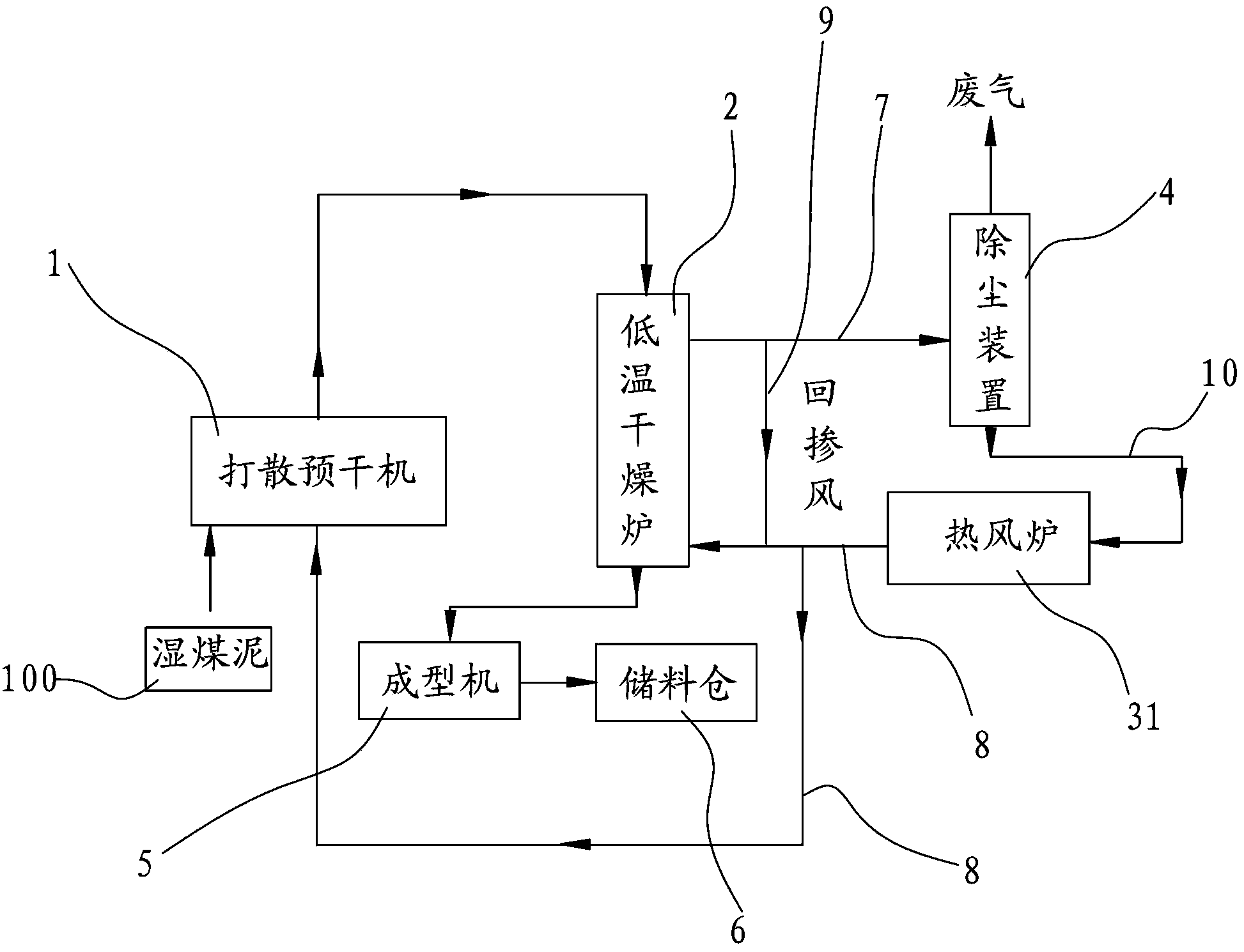

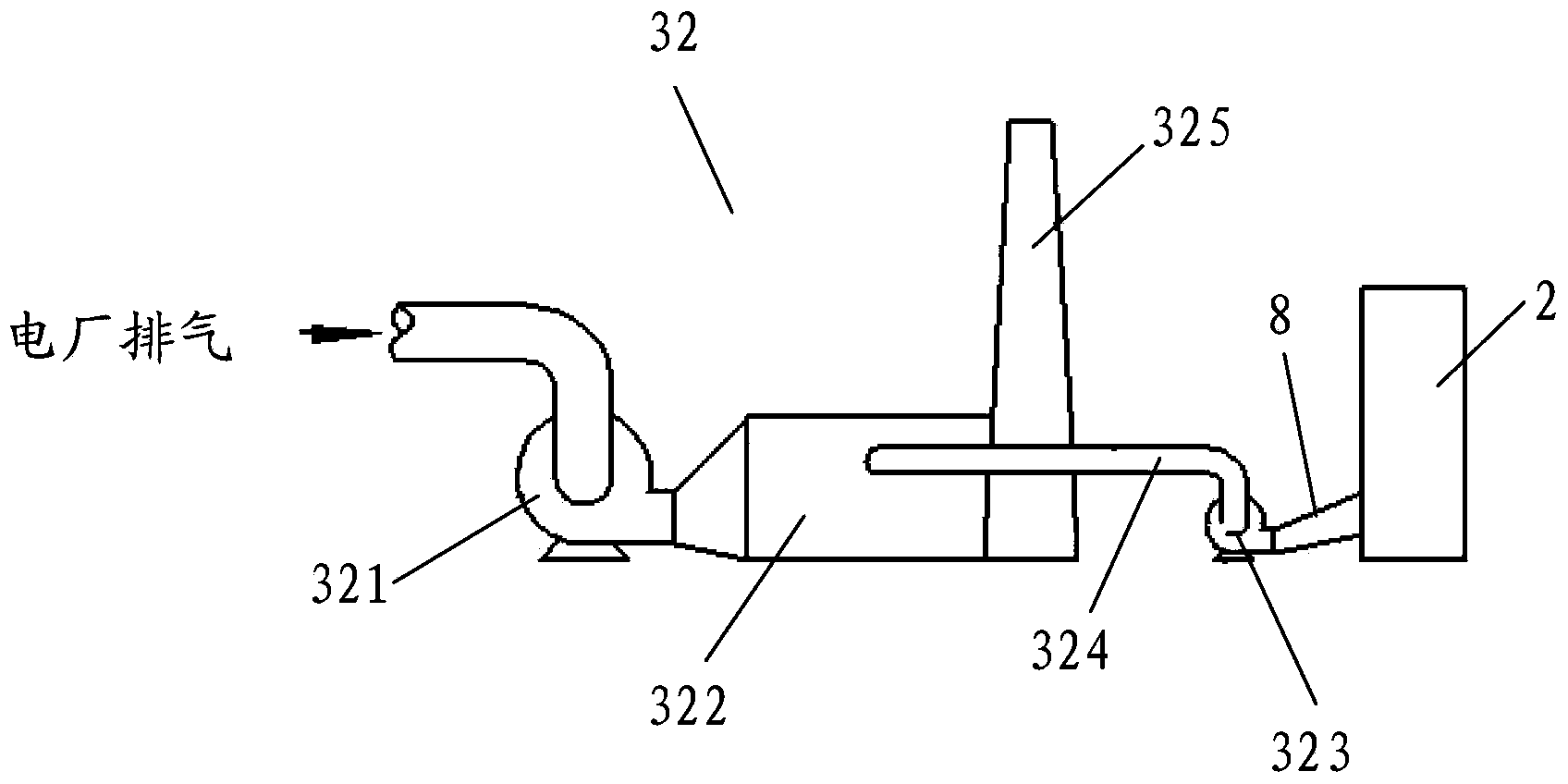

[0043] Such as figure 1As shown, a kind of coal slime drying system provided by the present invention comprises the break-up pre-dryer 1 that is used for breaking up wet coal slime 100 and pre-drying preliminary Carry out the low-temperature drying furnace 2 of low-temperature drying with the wet coal slime 100 of preliminary predrying, be used for forming the dry coal slime formed after the low-temperature drying furnace 2 low-temperature drying is molded 5, be used for low-temperature drying furnace 2 is discharged A dust removal device 4 for recovering coal ash and a heating device 3 for supplying hot air below 250°C to the dispersing pre-dryer 1 and the low-temperature drying furnace 2. The dispersing pre-dryer 1 is connected to the low-temperature drying furnace 2, and the The upper part of the drying furnace 2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com