Concrete pump truck and arm frame connecting mechanism thereof

A connecting mechanism and arm frame technology, which is applied in the field of concrete pump truck and its arm frame connecting mechanism, can solve problems such as cracked bolts, difficult long bridges, and uneven force on the turntable, so as to achieve a large-length bridge ratio and reduce Potential safety hazard, good effect on turntable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

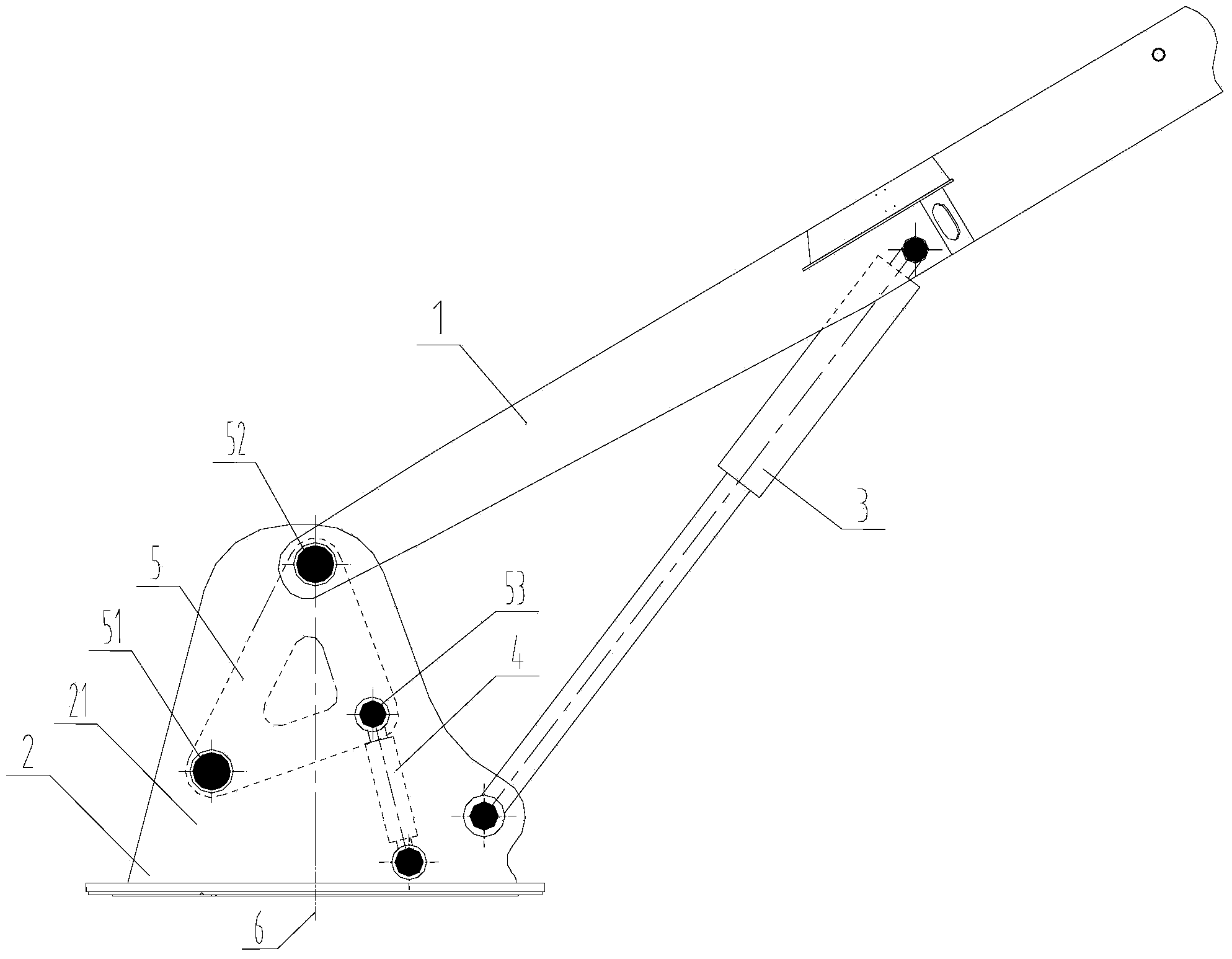

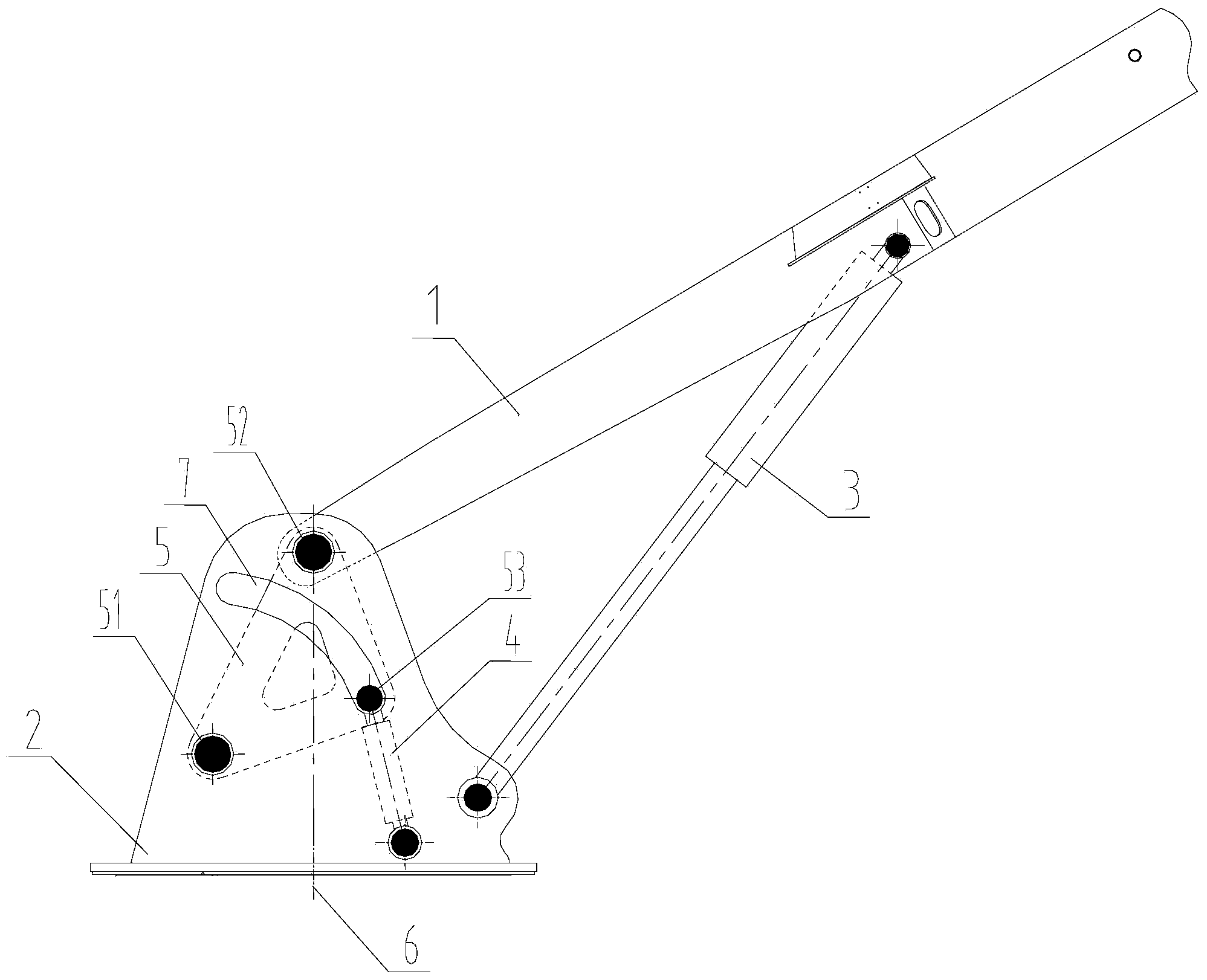

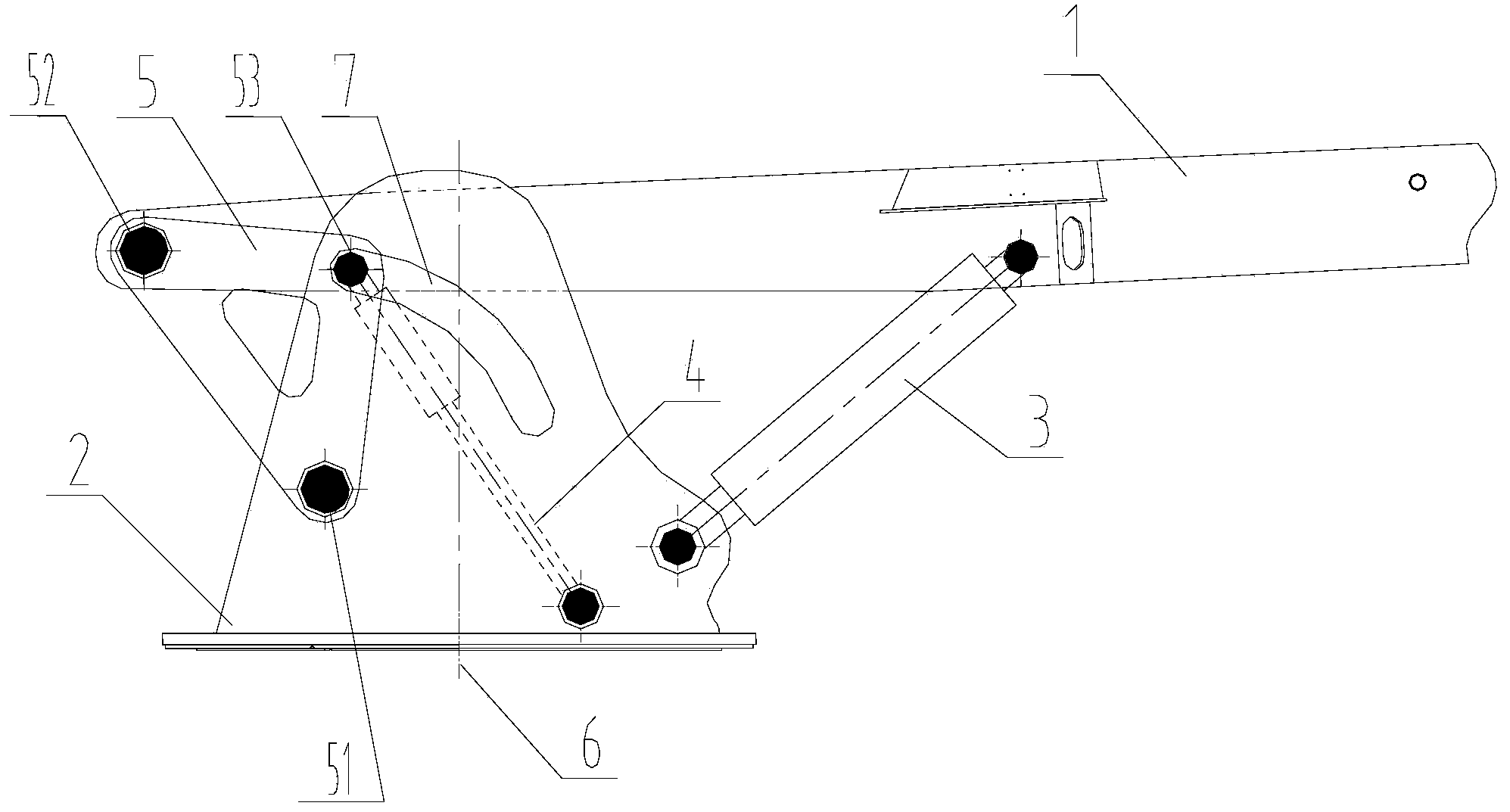

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The following will refer to the attached figure 1 To attach Figure 7 The present invention will be described in detail in combination with examples.

[0027] Such as figure 1 As shown, a boom connection mechanism provided by a specific embodiment of the present invention includes a first telescopic cylinder 3, a turntable 2 and a boom 1, and the two ends of the first telescopic cylinder 3 are respectively hinged to the turntable 2 and the boom 1; The boom connection mechanism also includes a connecting rod 5 and a telescopic mechanism 4, the connecting rod 5 is provided with a first hinge point 51, a second hinge point 52 and a third hinge point 53, the first hinge point 51 is hinged with the turntable 2, the second The hinge point 52 is hinged with the boom 1, the third hinge point 53 is hinged with one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com