A construction method for concrete pouring in super high-rise steel pipe columns

A construction method and technology of steel pipe columns, which are applied in construction, building structure, construction material processing and other directions, can solve the problems of long-term occupation of erection and dismantling labor and turnover materials, restricting the progress of the project, hidden dangers, etc., so as to reduce labor and The effect of turnover material consumption, reduction of comprehensive project cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

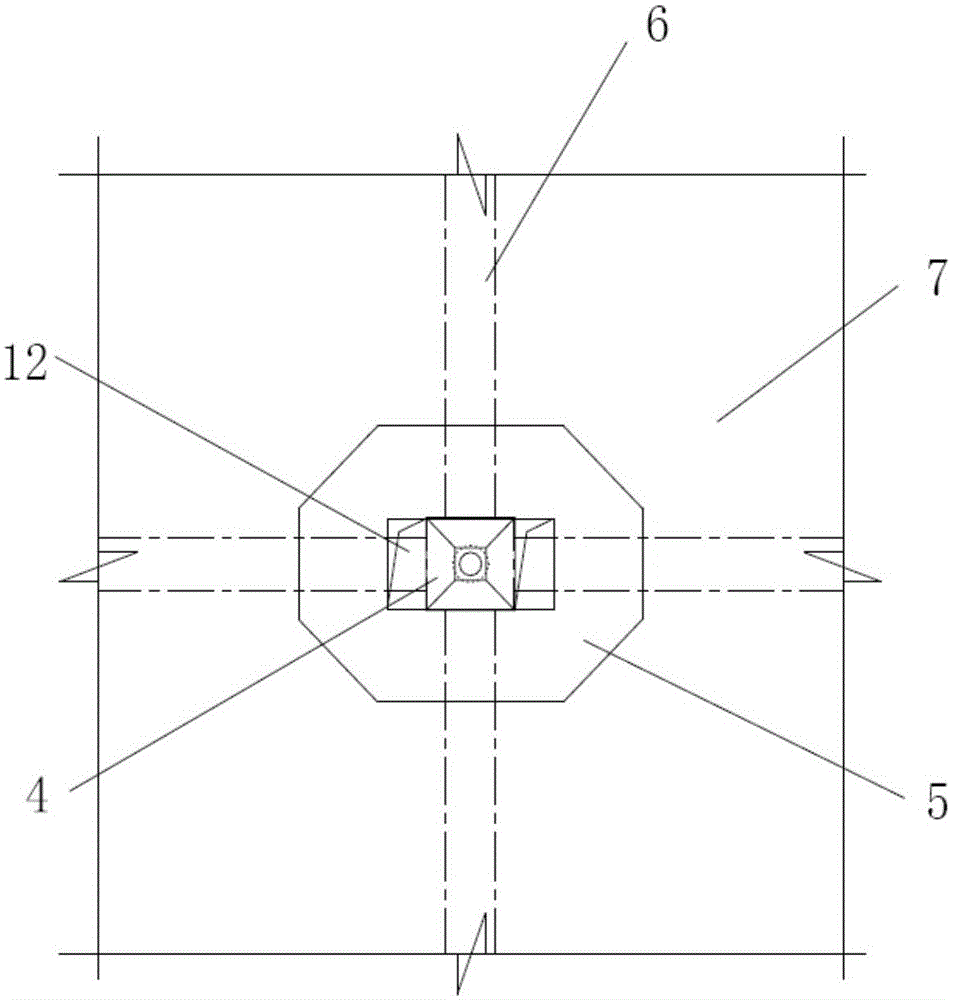

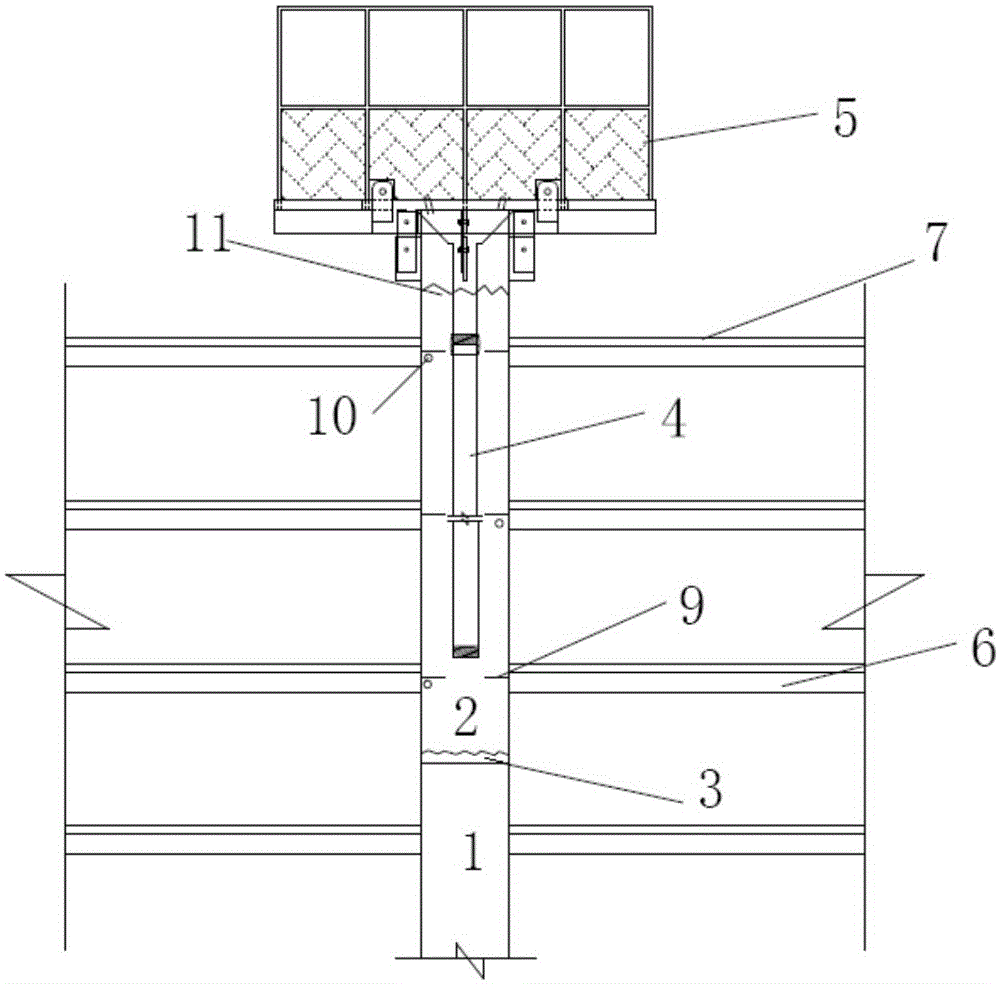

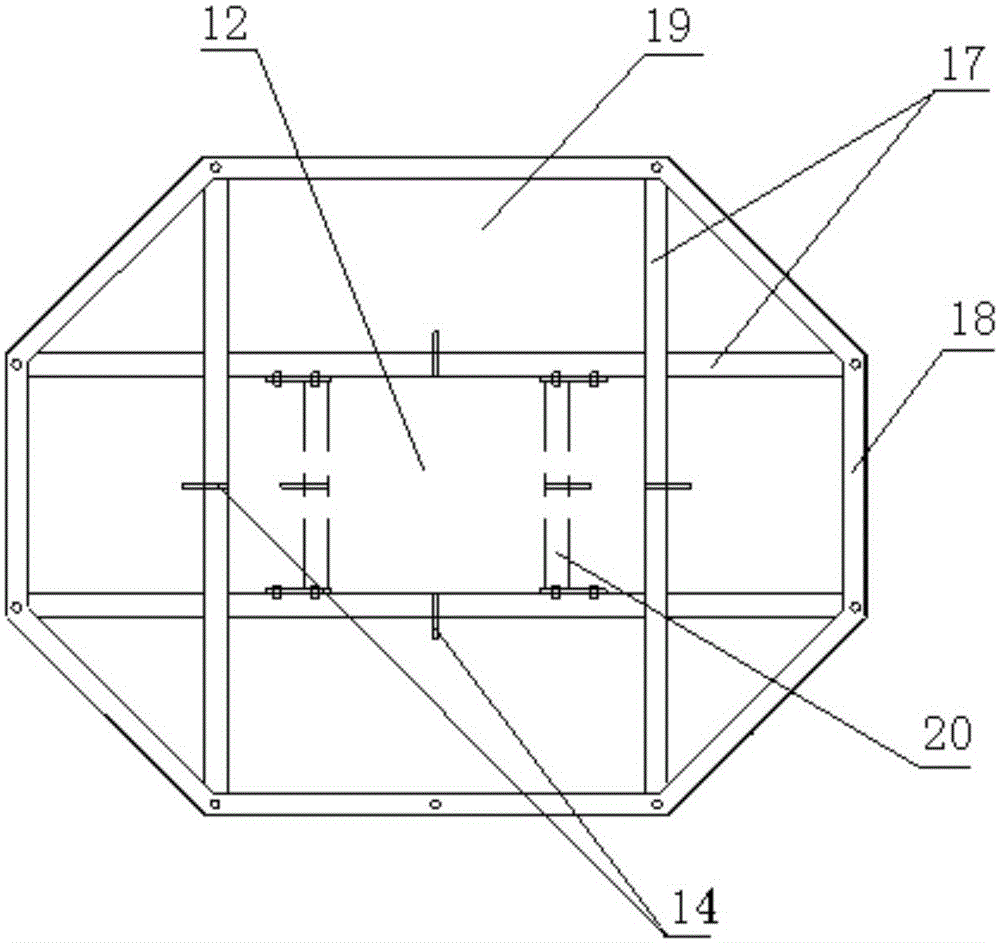

[0036] Such as Figure 1 to Figure 7 As shown, the concrete pouring method in the super high-rise steel pipe column specifically includes the following steps:

[0037] 1. Remove the sealing thin steel plate of the steel pipe column 1 in the previous section, and clean up the accumulated water and garbage in the column;

[0038] 2. Hoist the steel pipe column 2 of this section (usually a section of 3 floors, with a length of 10 meters), and connect it with the steel pipe column 1 of the previous section with connecting steel plates and bolts;

[0039] 3. After hoisting the steel beam 6 on the first floor of the steel pipe column 2 in this section, position the steel pipe column in this section, weld and fix it with the joint 3 of the steel pipe column in the previous section, and complete the weld flaw detection, and then complete the upper steel beam after hoisting , in the hoisting of the steel structure floor, for the uppermost layer of the section column, the floor slab 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com