Forecasting and optimizing method for ethylene cracking material configuration

A technology for ethylene cracking raw materials and optimization methods, applied in the field of chemical engineering, can solve problems such as rough results and inability to adjust device operating parameters in time

- Summary

- Abstract

- Description

- Claims

- Application Information

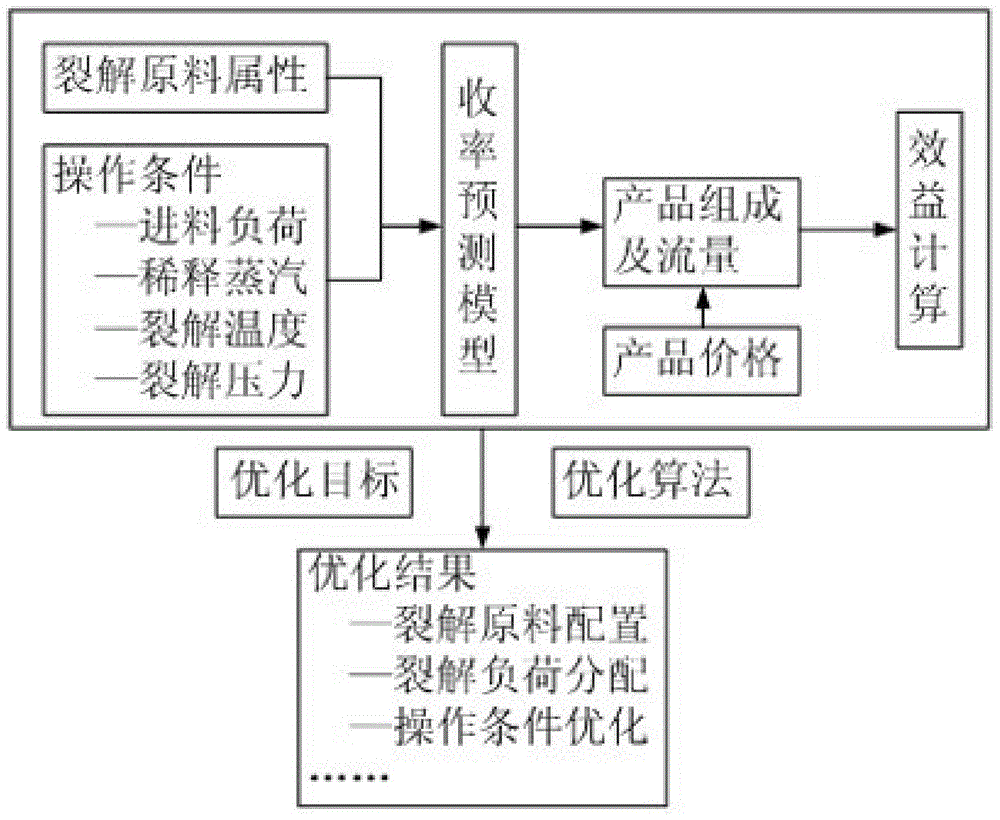

AI Technical Summary

Problems solved by technology

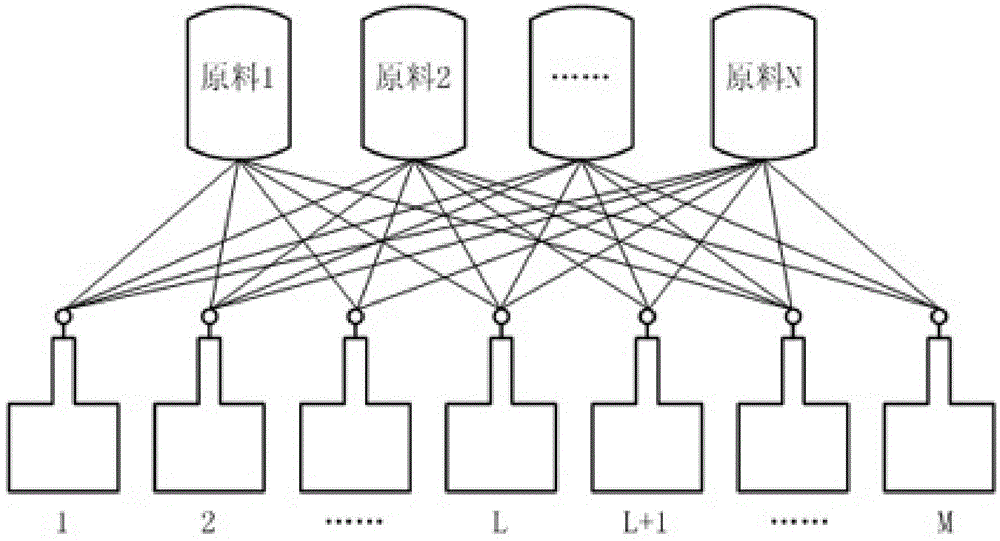

Method used

Image

Examples

Embodiment Construction

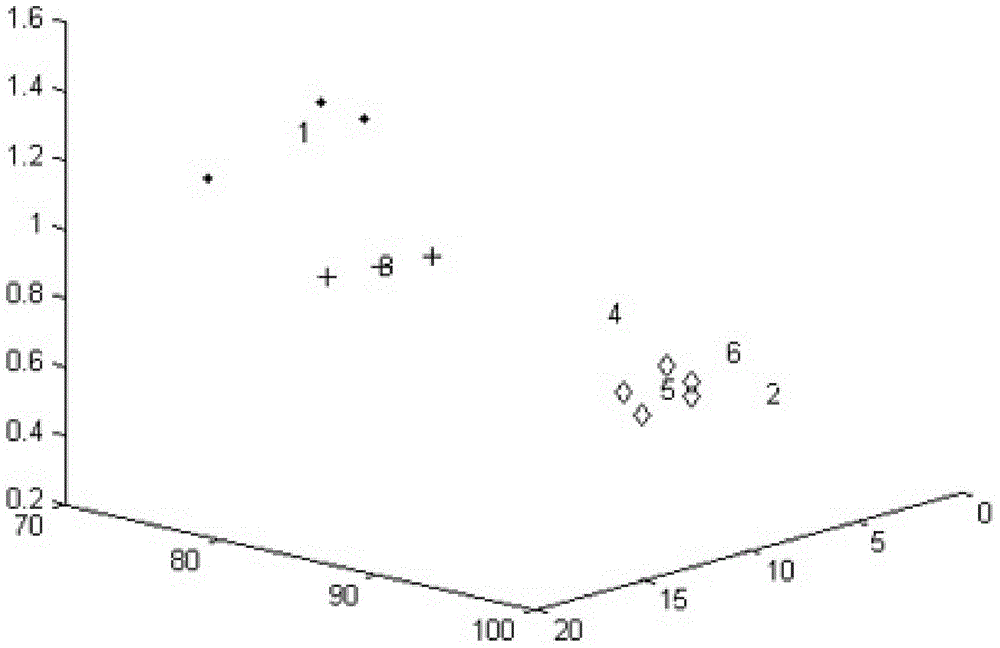

[0063] A method for predicting and optimizing the allocation of ethylene cracking raw materials in this specific embodiment is based on a cracking furnace group of a cracking device of a petrochemical company as an example, and calculates the ratio of raw material resources of all cracking furnaces. On the basis of the high yield of high-yield products, raw material supply price and product price, the optimization is carried out according to the demand for ethylene raw materials with the highest high-yield yield and the lowest equivalent ethylene cost of the ethylene plant. The specific calculation basis and optimized cracking raw material configuration results are shown in the attached Shown in Table 1 (this table shows the cracking raw material system and optimization results of the company in a certain month). The specific implementation steps are as follows:

[0064] 1 Actual industrial data acquisition and preprocessing

[0065] The hourly average on-site industrial data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com