Energy-saving glass

A technology of energy-saving glass and glass, which is applied in windows/doors, building components, building structures, etc., and can solve problems such as complex structures, no heat preservation, and no use of marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

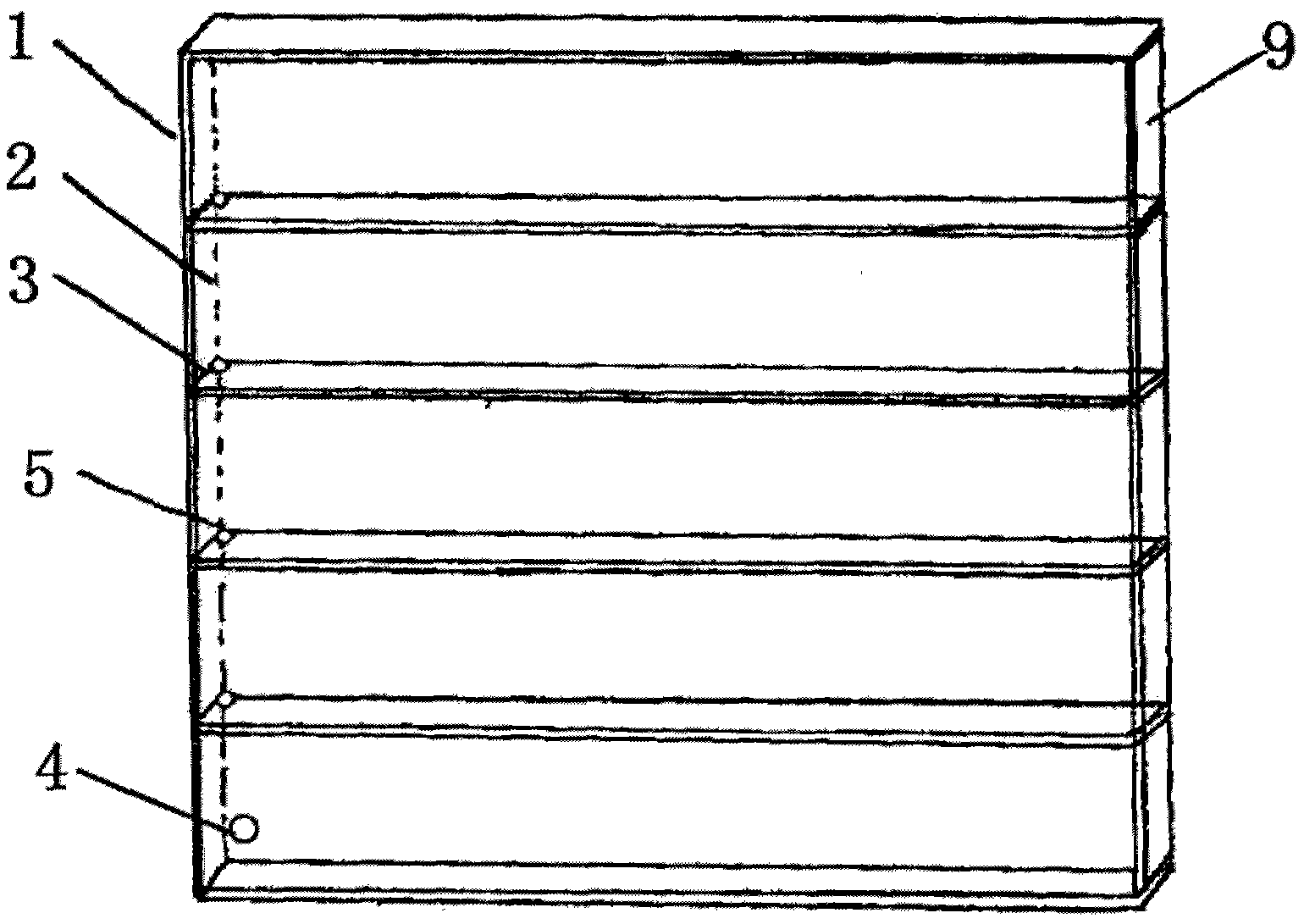

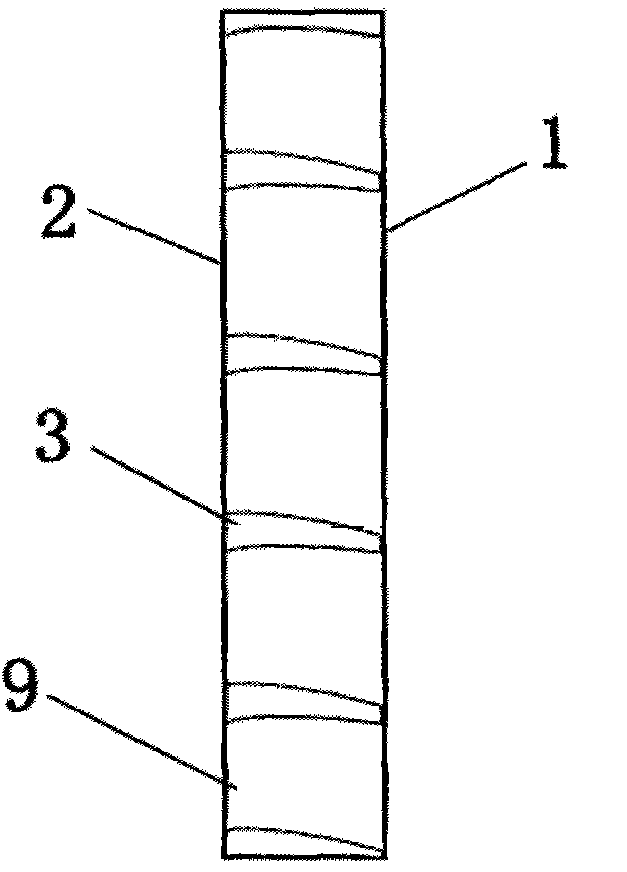

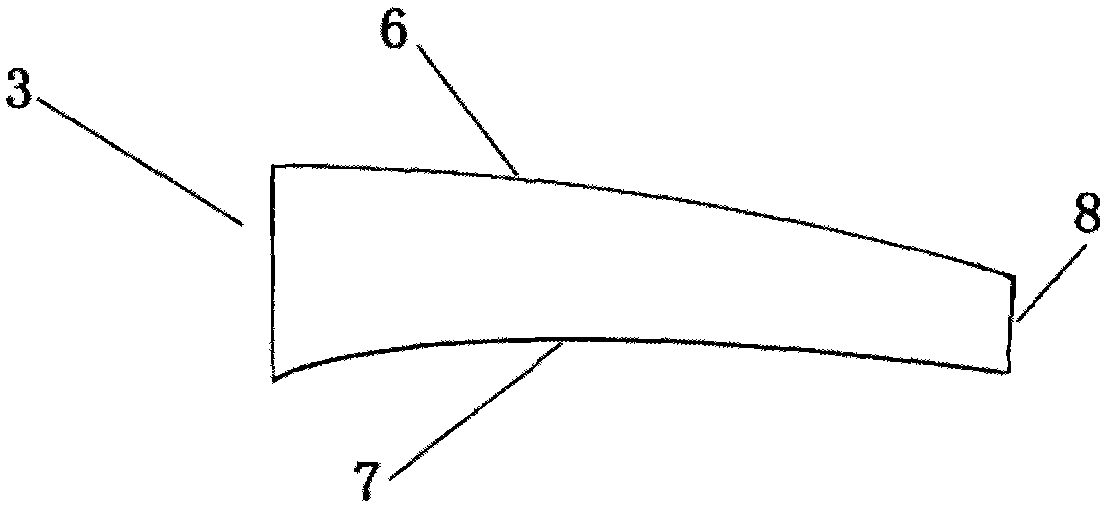

[0011] Such as figure 1 and figure 2 As shown, a kind of energy-saving glass is made up of outer glass 1 and inner glass 2; inner glass 2 is color-changing glass; A number of supporting ribs 3 are arranged in parallel between the layers of glass; air extraction holes 4 are opened on the outer layer of glass 1 (or inner layer of glass, edge-sealing glass). Such as figure 2 As shown, the inner and outer ends of the supporting rib 3 are respectively connected and fixed with the inner glass and the outer glass, and the left and right ends of the supporting rib are connected and fixed with the edge-sealing glass, and the inner and outer layers of glass are divided into several Chamber; such as Figure 4 As shown, there is a ventilation hole 5 on the longitudinal section of the supporting rib 3, which is located at one end of the supporting rib and is semi-cylindrical. The ventilation hole 5 connects the adjacent chambers. Such as image 3 and 4 As shown, the supporting rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com