Method and device for treating coking wastewater

A technology for coking wastewater and treatment method, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of slow reaction rate, high toxicity, poor biodegradability, etc., and achieve the effect of saving consumption, strong adaptability and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The treatment method of coking wastewater described in this embodiment specifically includes the steps of: in a subcritical state, add oxygen into 1L of coking wastewater as an oxidant, and then add catalyst K 2 CO 3 , to oxidize coking wastewater to produce hydrogen, wherein the reaction time is 60 s, the pressure is 25.00MPa, the temperature is 300°C, and the heating rate is 20°C / min;

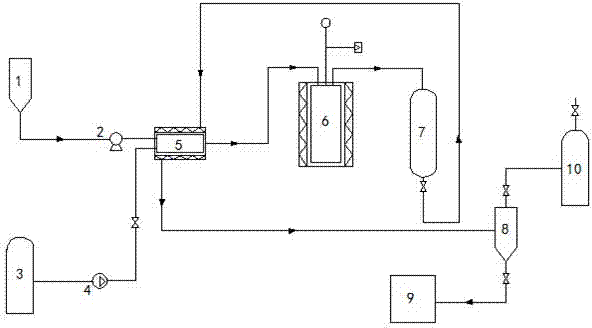

[0024] The reaction device for realizing the treatment method of coking wastewater described in this embodiment includes a coking wastewater storage tank 1, a high-pressure metering pump 2, an oxidant storage tank 3, a gas booster pump 4, a preheater 5, a supercritical reactor 6, Buffer tank 7, gas-liquid separator 8, liquid collection tank 9, gas collection tank 10, coking wastewater storage tank 1 and oxidant storage tank 3 are respectively connected to pre-heater 5 through high-pressure metering pump 2 and gas booster pump 4. The heater 5, the supercritical reactor 6, and the buffe...

Embodiment 2

[0031] The treatment method of coking wastewater described in this embodiment specifically includes the steps of: in a supercritical state, adding hydrogen peroxide into 1L of coking wastewater as an oxidizing agent, and then adding catalyst Na 2 CO 3 , to oxidize coking wastewater to produce hydrogen, wherein the reaction time is 400 s, the pressure is 23MPa, the temperature is 600°C, and the heating rate is 50°C / min;

[0032] The reaction device for realizing the treatment method of coking wastewater described in this embodiment includes a coking wastewater storage tank 1, a high-pressure metering pump 2, an oxidant storage tank 3, a gas booster pump 4, a preheater 5, a supercritical reactor 6, Buffer tank 7, gas-liquid separator 8, liquid collection tank 9, gas collection tank 10, coking wastewater storage tank 1 and oxidant storage tank 3 are respectively connected to pre-heater 5 through high-pressure metering pump 2 and gas booster pump 4. The heater 5, the supercritica...

Embodiment 3

[0039] The treatment method of coking wastewater described in this embodiment specifically includes the steps of: in a supercritical state, add oxygen into 1L of coking wastewater as an oxidant, then add a catalyst and then add catalyst K 2 CO 3 and Na 2 CO 3 mixture, where K 2 CO 3 and Na 2 CO 3 The mass ratio is 1:3 to oxidize the coking wastewater to produce hydrogen. The reaction time is 150 s, the pressure is 24.00 MPa, the temperature is 400°C, and the heating rate is 30°C / min;

[0040] The reaction device for realizing the treatment method of coking wastewater described in this embodiment includes a coking wastewater storage tank 1, a high-pressure metering pump 2, an oxidant storage tank 3, a gas booster pump 4, a preheater 5, a supercritical reactor 6, Buffer tank 7, gas-liquid separator 8, liquid collection tank 9, gas collection tank 10, coking wastewater storage tank 1 and oxidant storage tank 3 are respectively connected to pre-heater 5 through high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com