Rotating wheel type fixed discharge device

A fixed unloading and wheel-type technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reducing belt life, belt damage, resetting, etc., and achieve the effect of complete unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

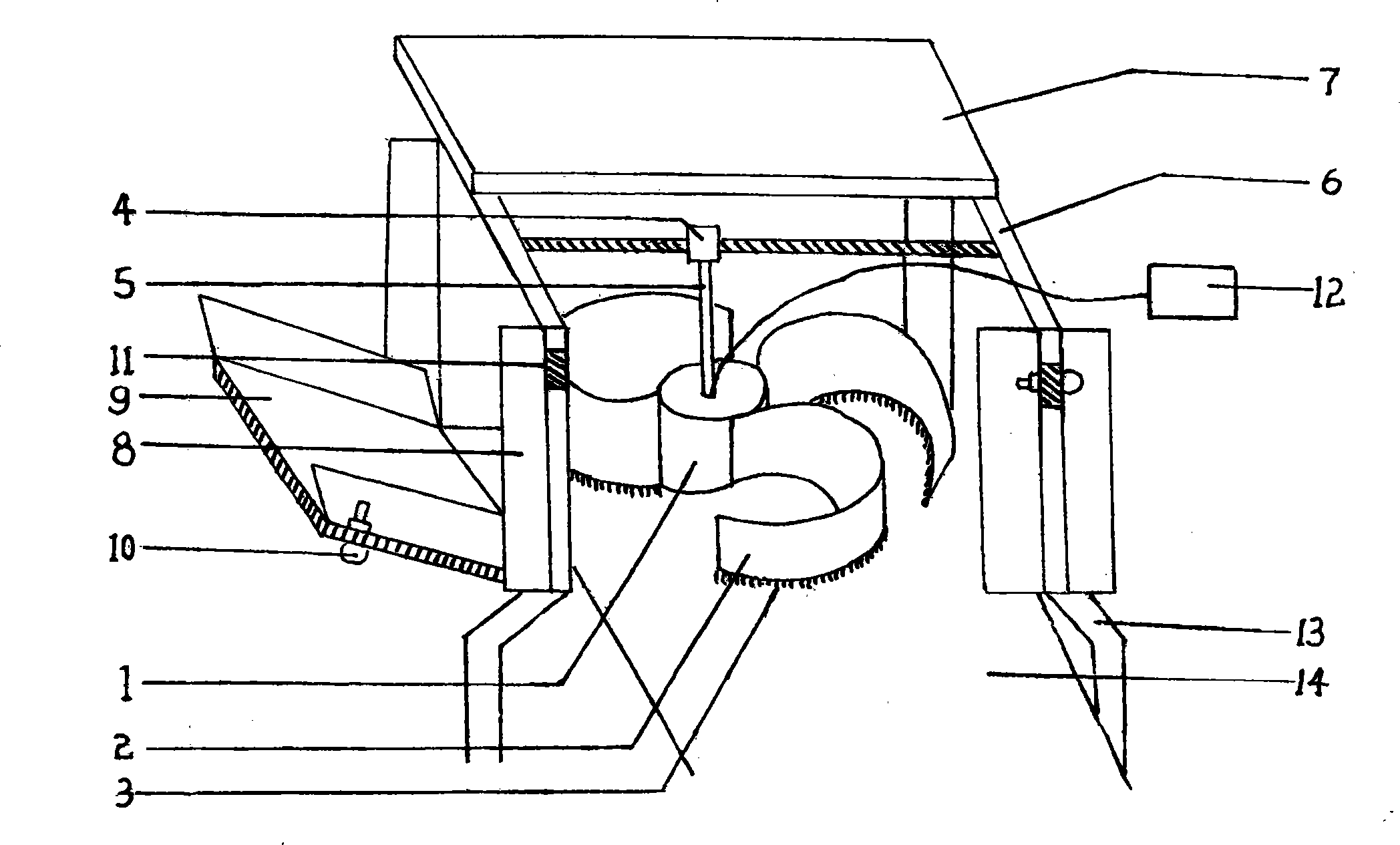

[0007] A rotary wheel type fixed unloading device, comprising a rotary wheel (1), a rotating sheet (2), a brush pad (3), a rotating shaft (4), a connecting rod (5), a frame (6), a sliding top plate ( 7), baffle plate (8), movable frame (9), bolt (10), bolt hole (11), runner driving device (12), bracket (13), belt (14), described runner (1 ) is provided with a rotating leaf (2), the rotating leaf (2) is provided with a brush pad (3), the upper part of the runner (1) is provided with a rotating shaft (4), a connecting rod (5), and the runner (1) Set in the frame (6), the frame (6) is provided with a sliding top plate (7), the frame (6) is provided with a bracket (13), and the two sides of the frame (6) are respectively provided with a baffle plate (8), a movable frame ( 9), the frame (6) side is provided with bolt holes (11), and the movable frame (9) is in the shape of a letter and a bolt (10) is established on one side, and the movable frame (9) passes through the bolt (10) ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com