Blocking edge for belt conveyor and belt conveyor

A belt conveyor and belt technology, applied in the field of belt conveyors with flanges, can solve the problems of high cost of corrugated flange belts, small conveying inclination angle, inability to transport vertically, etc., and achieve a wide range of conveying angles and low cost. , The effect of manufacturing and installation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

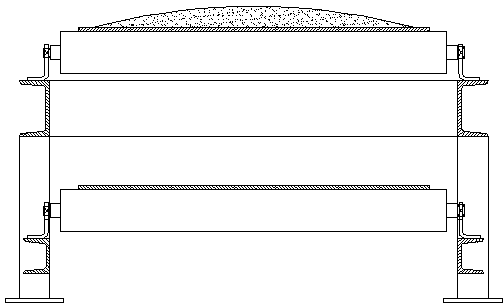

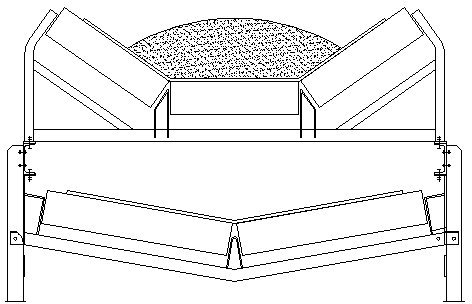

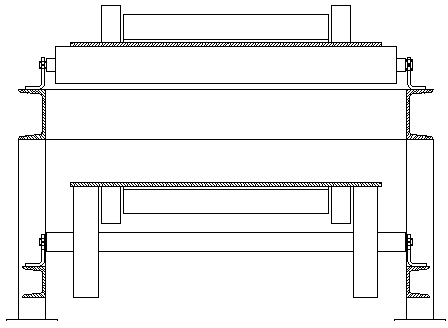

[0024] Such as Figure 6 As shown, the belt conveyor comprises a driven roller 1, a feed port 2, a flat idler roller 3, a plastic rib 5, a frame 6, a driving roller 7, a power unit 8 and a belt 9, and the belt 9 surrounds the driving roller 7 and The driven roller 1; the flat roller 3 is located at the lower part of the belt 9 between the driven roller 1 and the driving roller 7; the power device 8 drives the driving roller 7 to rotate, and the plastic rib 5 is evenly installed on the belt 9, and the scraping of the plastic rib The bottom surface 512 of the plate is flat against the plane of the belt 9, and the baffle rear portion 522 of the previous plastic rim and the plastic rim front 521 of the rear plastic rim partially overlap; the quantity of the installed plastic rim 5 should be enough to make the baffle The plate 52 completely covers both sides of the belt 9 .

[0025] When in use, start the power unit 8, the power unit 8 drives the driving roller 7 to rotate, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com